What Makes Buy Bimetallic Twin Screw Barrel Extruder a Smart Choice?

What Makes Buy Bimetallic Twin Screw Barrel Extruder a Smart Choice?

Why is a Bimetallic Twin Screw Barrel Extruder Essential for Modern Applications?

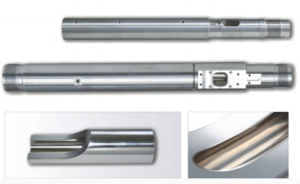

The Role of Twin Screw Technology in Enhanced Performance

Twin screw technology plays a role in modern extrusion processes because of its exceptional precision and efficiency capabilities. The twin screw barrel extruder is crafted to manage material compositions with finesse to achieve superior mixing, melting and metering results. The dual screw setup provides control over shear forces and temperature distribution, making it perfect for applications that demand consistent quality and high productivity levels. This cutting-edge technology guarantees that companies can fulfill the needs of present-day sectors—ranging from crafting durable plastics to fashioning consistent materials for specific uses.

Benefits of Bimetallic Construction in Extruders

Durability and Wear Resistance

Using a combination of metals greatly improves the strength of double screw barrel extruders by adding a layer of wear-resistant alloy inside them to resist damage from harsh materials over time. CHUANGRI SCREW’s bimetallic barrels incorporate tungsten carbide particles into a nickel alloy surface that resists corrosion well and offers superior wear resistance for applications with more than 35% abrasive fillers. This innovative design guarantees a lifespan compared to standard nitrided barrels.

Improved Heat and Corrosion Resistance

The layer of bimetallic material provides protection against heat and corrosion and is ideal for handling materials with a high calcium powder content or that need to withstand high temperatures effectively. CHUANGRI SCREW utilizes tungsten carbide nickel alloy coatings with a hardness of 1,350 to 2,100 HV in order to work with materials having up to 380% calcium powder. Not only does this prolong the lifetime of the equipment, but even under severe operating conditions, its performance remains the same.

How Does a Bimetallic Twin Screw Barrel Extruder Improve Efficiency?

Optimizing Material Processing with Precision Design

Craftsmanship plays a role in maximizing the efficiency of material processing operations. CHUANGRI SCREW’s twin screws with bimetallic properties are meticulously crafted to improve the plasticization process and uphold melt quality even during rapid processing rates. The incorporation of components like barrier areas and well-designed flow passages promotes effective blending and lowers energy usage. These design elements empower producers to handle materials, such as those with high fillers or corrosive properties without sacrificing excellence or productivity.

Achieving Consistent Output and Reduced Downtime

Maintaining output is essential in manufacturing operations. The twin screw barrel extruders are built to reduce downtime with their strong design and precise engineering techniques. The use of casting by CHUANGRI SCREW guarantees even thickness and durability of the bimetal layer for reliable performance over prolonged durations.

What Should You Consider When You Buy a Bimetallic Twin Screw Barrel Extruder?

Importance of Material Compatibility and Customization Options

When choosing a bimetallic twin screw barrel for your needs and applications in the process of processing, ensuring compatibility with the materials used in the production process of different plastic products, which come with certain processing properties that call for specialized equipment to generate maximum results, is of utmost importance. CHUANGRI SCREW’s screws are designed specifically to assist your extrusion processes by offering flexibility for various diameters and lengths and compatibility with application on various brands and models. This flexibility enables manufacturers to utilize a wide range of materials, such as highly filled or corrosive materials, without compromising the overall quality of the end products manufactured.

Personalization choices are also vital for optimal effectiveness. CHUANGRI SCREW provides solutions through its innovative research and development department that utilizes state-of-the-art tools like AutoCAD for creating screws and barrels tailored to meet precise manufacturing needs. Whether dealing with PVC pipes or SPC flooring having equipment personalized according to your requirements guarantees production and minimizes wastage.

Ensuring Long-Term Cost-Effectiveness Through Quality

It’s a good idea to spend money on a notch bimetallic twin screw barrel extruder in order to save money in the long run. The strength of the machine is one factor that makes it resistant to wear and tear over time. CHUANGRI SCREW bimetallic barrels are produced using carbide particles uniformly mixed in a corrosion-resistant nickel alloy matrix. This unique composition lends strength even in extreme conditions and minimizes the need for repeated replacement or repair. This ultimately means savings on operational costs.

Why Choose CHUANGRI SCREW for Your Bimetallic Twin Screw Barrel Extruder Needs?

Advanced Production Techniques and Superior Materials

At CHUANGRI SCREW, we take pride in our use of production methods to create top-notch bimetallic twin screw barrel extruders. Our adherence to the ISO 9001;2008 standard guarantees efficient production processes at every step of the way. Our manufacturing process is careful. Carried out using modern CNC machining tools for tasks, like threading and polishing as well as applying nitriding and bimetallic and alloy coatings to achieve top-quality products.

We carefully choose high quality materials that adhere to standards to guarantee longevity and efficiency in our products performance examples are our bimetallic barrels crafted with tungsten carbide particles evenly distributed in a nickel alloy matrix resistant to corrosion. This blend offers excellent durability against wear and maintains stable heat levels even in challenging operating conditions.

Exceptional Durability and Performance Standards

Our extruders come equipped with HVOF metallurgical bonding technology that ensures a metallurgical bond between the alloy coating and the base material. This effectively eliminates problems, like detachment or peeling of the alloy layer.

The centrifugal casting technique guarantees thickness and strength throughout the bimetallic layer structure we use in our extruders to withstand filler content of up to 35% ensuring optimal performance levels are maintained without any compromise in quality standards or functionality requirements. The added advantage of self-cleaning features in our products aids in transitions between materials or colors, resulting in reduced downtime and improved operational efficiency overall.

If you are working with PVC pipes that have a lot of calcium carbonate or making SPC flooring that needs temperature management, our bimetallic twin screw barrel extruders ensure reliable quality and productivity. Specifically, our conical twin screw barrels are made for places with calcium carbonate levels. They help improve the blending process while ensuring mixing quality.

Frequently Asked Questions about Bimetallic Twin Screw Barrel Extruder

Q: What is a bimetallic twin screw barrel extruder?

A: A bimetallic twin screw barrel extruder is a sophisticated equipment utilized in the process of extrusion of plastic. It includes twin-screw, bimetallic barrel-type machines with greater wear life and longer life for the extruder, especially for hard application.

Q: Why choose a bimetallic twin screw barrel extruder?

A: Choosing a bimetallic twin screw barrel extruder adds durability, efficiency, and performance. The bimetallic coating is resistant to wear and corrosion, offering a longer lifespan and making it ideal for high-demand use and challenging materials like PVC and compound plastics.

Q: What materials can a bimetallic twin screw barrel extruder process?

A: A bimetallic twin screw barrel extruder is able to process a variety of materials, including PVC, PE, PP, ABS, and other thermoplastics. It’s especially suitable for highly abrasive or high-viscosity material processing because of its strong, wear-resistant construction.

Q: How do I maintain a bimetallic twin screw barrel extruder?

A: To maintain a bimetallic twin screw barrel extruder in proper working condition, clean the screws and barrels regularly, check for wear and tear, and change the damaged components. Proper lubrication of the moving parts and frequent checking for cracks or deposits can extend its working life extensively.