What You Need to Know Before Buying a Mini Single Screw Barrel Extruder

What You Need to Know Before Buying a Mini Single Screw Barrel Extruder

Why Choose a Mini Single Screw Barrel Extruder?

The choice of equipment for your plastic processing requirement is critical in order to realize maximum efficiency and highest quality norms being invariably and faultlessly attained. Mini single-screw barrel extruders are known for their design and high performance potential, which cater to varied requirements with flexibility as the foremost concern. Such machines work best in applications where small-scale manufacture or specialized use is carried out where precision and consistency are considerations.

Key Features of Mini Single Screw Barrel Extruders

Small single-screw barrel extruders are made to process a variety of materials in an effective way without sacrificing their small size at all at the cost of their performance level. They are equipped with a number of features that optimize their utility like:

- High Efficiency:These extruders provide decent output rates with energy efficiency.

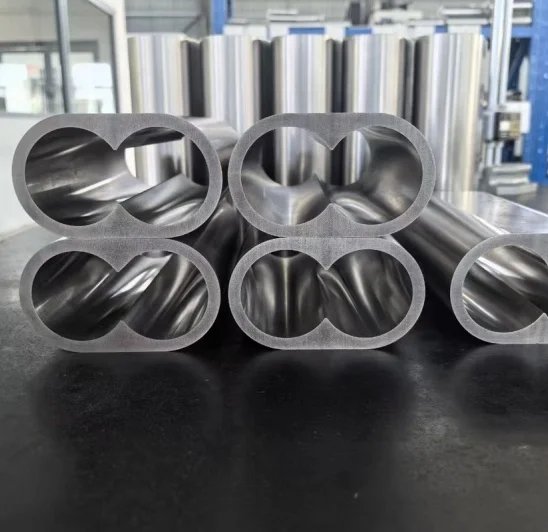

- Customizable Designs:Organizations like CHUANGRI SCREW offer tailored solutions to fit one-of-a-kind processing requirements. Different kinds of screws are produced to achieve different processing results.

- Durable Materials:High strength materials like 38CrMoAlA and SKD61 are used in making these extruders which have a high lifespan and have good wear resistance and corrosion.

- Precision Engineering:Precision CNC machining provides tight tolerance as well as exceptional product quality with high performance.

Advantages of Using a Mini Single Screw Barrel Extruder

- Space-Saving Design:Their smaller size makes them ideal for installations with limited space.

- Cost-Effective Operation:Lower initial investment and operational costs compared to large systems.

- Versatility:Can work with a wide range of applications, including plastic recycling, small product manufacturing and specialty product creation.

- Ease of Maintenance:Easy design allows easy cleaning and maintenance, reducing downtime.

- High Performance in Small Batches:Ideal for creating high-quality outputs in small batches.

How to Select the Right Mini Single Screw Barrel Extruder?

Choosing the single-screw compact barrel extruder needs careful consideration of your specific needs and requirements in order to find the most suitable match for your application.

Factors to Consider When Choosing an Extruder

Choosing the extruder is highly dependent on the material you will process since various plastics have varying process behavior and characteristics. Make sure that the selected extruder suits your material’s melting point as well as the viscosity to create compatibility and allow proper processing.

Assess the size of your production and choose an extruder that matches the required capacity level accordingly. Mini single-screw barrel extruders work well for small-scale projects. They can be adjusted for higher output if necessary.

What Are the Common Applications of a Mini Single Screw Barrel Extruder?

Small single screw barrel extruders have found a niche in various industrial environments due to their compact size and excellent performance capabilities. They are created to meet particular requirements by providing accuracy and effectiveness in handling a diverse array of materials.

Industries That Benefit from Mini Single Screw Barrel Extruders

Mini single screw barrel extruders play a role in industries that value accuracy and flexibility due to their adaptable design which caters to various sectors such, as;

- These extruders are highly helpful in the Plastic recyclingsince they efficiently and effectively convert rejected plastics into materials that can be utilized. Their pelletizing and recycling screws offer customer-oriented solutions with their durable build and wear- and corrosion-resistant special coatings.

- In the field, precision is crucially important where mini single screw barrel extruders are employed to create small components,like catheters and tubing from medical grade plastic with a consistent quality output, which suits this industry perfectly.

- The production of parts involves the utilization of these extruders to manufacture specialized components for vehicles benefiting from their small size to craft detailed parts with exceptional accuracy.

- The packaging industry leverages these machines to produce plastic films, containers and various packaging materials efficiently. CHUANGRI SCREW’s blown film screws deliver a 20% increase in productivity over models while ensuring precise control over the melt temperature.

- The electronics sector makes use of single-screw barrel extruders to manufacture parts,such as cable insulation and connectors that require consistency and material strength.

Why CHUANGRI SCREW is Your Go-To Choice for Mini Single Screw Barrel Extruders

An Overview of CHUANGRI SCREW’s Expertise in Manufacturing

CHUANGRI SCREW has established itself as a global player in crafting top-notch screws and barrels since its inception in 1990. With a wealth of expertise spanning over three decades under its belt, we focus on developing custom equipment to cater to a range of industrial requirements.

CHUANGRI SCREW boasts the latest manufacturing skill and technology. We possess state-of-the-art CNC machining machines utilized for various operations from threading and milling to polishing to keep strict tolerances and deliver quality products. From nitriding to coating applications, the use of advanced technologies is a key element of the product’s durability. They are market leaders because they concentrate on innovation and customer satisfaction.

Unique Features of CHUANGRI SCREW’s Mini Single Screw Barrel Extruders

We use engineering methods to guarantee accuracy in all parts produced. Our extruders are crafted with measurements to enable steady operation and top-notch results. CHUANGRI SCREW’s screws are created to enhance plasticizing efficiency and achieve consistent melt quality at rapid processing rates.

CHUANGRI SCREW’s blown film extrusion screws deliver a production increase of up to 20% showcasing their dedication to innovation and productivity improvement. These improvements not only cut down on expenses but also promote eco-friendly manufacturing practices.

Looking for cost mini single screw barrel extruders that deliver exceptional performance? CHUANGRI SCREW is the go-to option for businesses in search of quality and affordability combined.

Frequently Asked Questions about Mini Single Screw Barrel Extruder

Q: Which is better, single screw or twin screw extruders?

A: Briefly, we can say that if you need a simpler and less expensive choice, you might opt for a single screw extruder. If fine control and versatility are significant in your production, you can prefer a twin screw extruder.

Q: What is a mini single screw barrel extruder used for?

A: It’s primarily employed for small-sized plastic processing, laboratory testing or sample manufacturing. Its compact design makes it ideal for research or limited space setups.

Q: Can it process different types of plastic?

A: Yes, it can process a range of thermoplastics such as PE, PP, PVC and ABS, depending on the screw design and temperature control system.

Q: How do I maintain a mini single screw extruder?

A: Regularly clean the barrel, inspect the screw for wear and maintain well lubrication. Avoid overheating and follow factory maintenance schedules.