Why Expert Screw and Barrel Repair is Crucial for Industrial Efficiency

Why Expert Screw and Barrel Repair is Crucial for Industrial Efficiency

What Makes Screw and Barrel Repair Essential for Industrial Operations?

The Role of Screws and Barrels in Manufacturing Processes

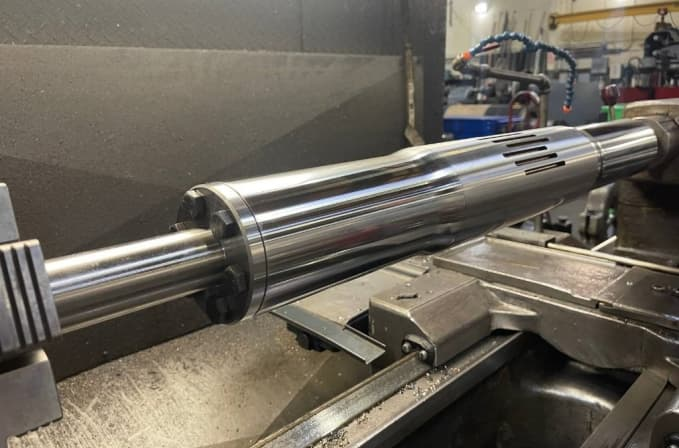

Screws and barrels serve as vital elements in industrial equipment. These components operate in critical processes including extrusion and injection molding. Their function facilitates the consistent flow and treatment of various compounds. This includes plastic polymers and rubber materials. These machine parts perform essential operations: material transportation, thermal fusion, precise measurement and fluid displacement. Their role proves indispensable across multiple sectors: From car component fabrication to container material manufacturing, these elements guarantee the streamlined manufacturing operations and consistent product excellence.

CHUANGRI SCREW recognizes each substance requires customized handling solutions. Our technical team develops our injection molding screws that enhance the output efficiency, production throughput and operational performance. They manage shear stress well and maintain consistent melt quality. Their robust build supports processing various resin types. This makes them suitable for applications like automotive components and medical equipment.

Common Issues That Affect Screw and Barrel Performance

Industrial screws and barrels face challenges due to constant exposure to high temperatures and harsh substances in corrosive environments. These conditions can cause wear over time and lower efficiency. Common issues include:

- Abrasion:Constant contact with hard fillers or glass fibers wears down screw flights.

- Corrosion:Chemicals encountered during processing can degrade the material of screws and barrels.

- Deformation:Intense operational pressures can cause warping or bending.

- Build-up of Residue:Imperfect polishing can cause material adhesion, hindering smooth operation.

How Neglecting Repairs Impacts Industrial Efficiency

Failure to address maintenance of screws and barrels can significantly impact industrial processes. Negative effects may include heightened energy usage as machinery exerts more effort to sustain production rates. Furthermore, damaged screws may lead to variations in product quality caused by uneven material melting or mixing.

Regularly occurring malfunctions resulting from overlooked upkeep interrupt production timelines and result in periods of inactivity. Furthermore, substituting impaired parts incurs significantly higher costs compared to routine maintenance or minor fixes.

How Can Timely Repairs Save Costs and Enhance Productivity?

The Financial Benefits of Preventive Maintenance

Routine maintenance offers significant cost savings by prolonging the service life of screws and barrels. Addressing minor wear promptly prevents more serious damage from developing. This proactive approach:

- Minimizes unplanned equipment downtime

- Reduces the need for expensive component replacements

- Maintains consistent production quality

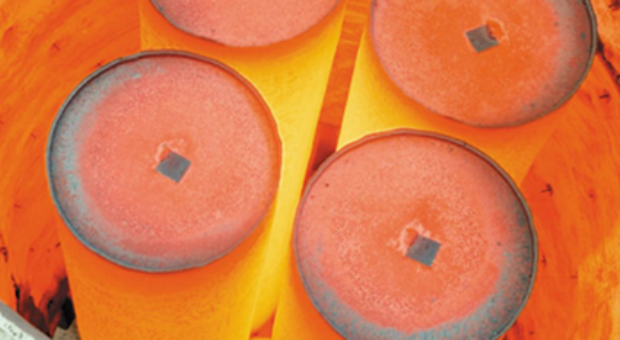

At CHUANGRI SCREW, we employ cutting-edge HVOF (High Velocity Oxygen Fuel) technology to apply tungsten carbide coatings to the Bimetallic Screw. This specialized thermal spray process creates an ultra-dense, metallurgically bonded protective layer that significantly improves component durability. The tungsten carbide coating provides exceptional resistance to both abrasive wear and chemical corrosion, effectively doubling or tripling the service life of these critical components compared to standard screws.

At CHUANGRI SCREW, we employ cutting-edge HVOF (High Velocity Oxygen Fuel) technology to apply tungsten carbide coatings to the Bimetallic Screw. This specialized thermal spray process creates an ultra-dense, metallurgically bonded protective layer that significantly improves component durability. The tungsten carbide coating provides exceptional resistance to both abrasive wear and chemical corrosion, effectively doubling or tripling the service life of these critical components compared to standard screws.

Minimizing Downtime Through Expert Repairs

When machines fail, it disrupts manufacturing businesses. It slows production and affects profits. Hiring technicians to repair equipment quickly restores smooth operation. This also prevents any decline in quality.

Extending the Lifespan of Industrial Equipment

Regular maintenance and timely repairs help extend the lifespan of industrial machinery. They prevent gradual wear and tear from building up. Nitriding offers heat resistance properties that enable screws to endure high operating temperatures without deterioration occurring over time or use wear and tear issues arising from it. Likewise, our quenching method boosts surface hardness levels that ultimately lead to improved durability of the components when subjected to mechanical stresses.

Regular maintenance and timely repairs help extend the lifespan of industrial machinery. They prevent gradual wear and tear from building up. Nitriding offers heat resistance properties that enable screws to endure high operating temperatures without deterioration occurring over time or use wear and tear issues arising from it. Likewise, our quenching method boosts surface hardness levels that ultimately lead to improved durability of the components when subjected to mechanical stresses.

Why Should You Rely on Professionals for Screw and Barrel Repair?

The Risks of DIY or Inexperienced Repairs

Amateur repairs on screws and barrels typically do more harm than good. These aren’t your average machine parts – they’re high-precision components meticulously designed to survive brutal operating environments. We’re talking about parts that must endure:

- Sustained temperatures that would warp ordinary steel

- Constant bombardment from chemically aggressive materials

- Relentless mechanical stresses that test structural limits

What many don’t realize is that these aren’t just metal parts – they’re carefully calibrated systems. The wrong repair approach can create hidden weak points that fail under stress and throw off the delicate balance needed for proper material flow. This is particularly critical because screws receive specialized treatments like nitriding – a precise thermal process where components are hardened in controlled nitrogen-hydrogen atmospheres. When untrained individuals attempt repairs, they often fail to properly address core issues like material deformation or surface degradation. Without access to industrial-grade equipment and technical know-how, their makeshift solutions frequently underperform. Worse still, improper handling during reinstallation often introduces new problems – misaligned components create uneven stress distribution, while surface damage from incorrect tools accelerates wear. These substandard repairs typically compound existing issues rather than solving them, leading to cascading operational failures that manifest weeks or months later.

Key Qualities to Look for in a Repair Service Provider

It is very important to find a company that can demonstrate professional capabilities, efficiency, commitment to quality assurance and customer-oriented response capabilities.

- The expertise required in this field involves a comprehension of the mechanics behind screws and barrels, where skilled engineers excel in creating tailor made solutions to cater to diverse manufacturing requirements.

- Cutting-edge technology plays a role in effective repairs by utilizing advanced methods,like nitriding and bimetallism coatings, along with electroplating techniques, which are key to ensuring durability and thermal stability in surface layers during the repair process.

- Prompt Service is essential for minimizing costs associated with downtime in operations and ensuring repairs are carried out efficiently,which schedules production immediately upon confirmation of drawings and dispatches standard stock models within three days.

- Thorough Quality Assurance Measures:Stringent inspection processes guarantee that refurbished parts adhere to norms from choosing materials to conclusive assessments. It is meticulously supervised to ensure top-notch outcomes.

- Customer Service Department: A trustworthy company should assist in completing repairs. We are committed to handling any quality concerns that arise during the warranty period following the completion of an order.

What Sets CHUANGRI SCREW Apart in the Industry?

Our Expertise in Screw and Barrel Repair Services

Specialized Solutions for Precision Repairs

CHUANGRI SCREW has built its reputation as an expert in screw and barrel repair. For more than 30 years, we have provided customers with specialized knowledge and exacting precision. Screws and barrels play a vital role in extrusion and injection molding. These components constantly face extreme conditions. High temperatures and abrasive materials gradually degrade their performance. Such challenges require customized solutions and precise repair techniques.

High-Quality Materials Used in Restorations

Quality stands at the core of our repair operations at CHUANGRI SCREW. We achieve this by integrating premium-grade materials throughout our restoration processes. Our specialists employ advanced alloys including tungsten carbide and nickel-based formulations, renowned for their exceptional wear protection and extended service capabilities. Each material undergoes rigorous selection to precisely match specific repair requirements. For example:

- Tungsten Carbide Coatings:Applied using HVOF (High-Velocity Oxygen Fuel) technology for superior abrasion resistance.

- Nickel-Based Alloys:Known for their corrosion resistance, these alloys ensure longevity even in chemically aggressive environments.

- Bimetallic Liners:Featuring tungsten carbide particles within a corrosion-resistant nickel alloy matrix for enhanced performance.

Our thorough examination processes ensure that each refurbished part meets guidelines effectively and efficiently through the use of top-notch materials and precise craftsmanship to yield durable outcomes that optimize the performance of industrial equipment over the long term.

Commitment to Client Satisfaction and Long-Term Results

At CHUANGRI SCREW, we understand every operation has unique demands. That’s why we don’t offer one-size-fits-all solutions – we create personalized maintenance plans designed around your specific processing challenges and production goals. Our engineers work shoulder-to-shoulder with your team to develop precision strategies that boost machine performance while minimizing unplanned stoppages. Our offerings encompass checks, wearing assessments and performance appraisals to catch possible risks in their bud.

At CHUANGRI SCREW, we understand every operation has unique demands. That’s why we don’t offer one-size-fits-all solutions – we create personalized maintenance plans designed around your specific processing challenges and production goals. Our engineers work shoulder-to-shoulder with your team to develop precision strategies that boost machine performance while minimizing unplanned stoppages. Our offerings encompass checks, wearing assessments and performance appraisals to catch possible risks in their bud.

Frequently Asked Questions about Screw and Barrel Repair

Q: What is screw and barrel repair?

A: Screw and barrel repair involves professionally restoring worn extrusion components to their original specifications. Our certified technicians meticulously rebuild damaged parts using precision machining and advanced coating technologies.

Q: Why do screw and barrel need repair?

A: Constant exposure to extreme conditions causes gradual deterioration: metal surfaces wear down from abrasive materials, high temperatures degrade structural integrity, and chemical corrosion eats away at components. Without proper maintenance, this leads to inefficient melting, poor mixing quality, and eventual machine failure.

Q: How often should screw and barrel be repaired?

A: For most plastic extrusion operations running 24/7, we recommend complete inspection every 8-12 months. Actual repair frequency varies based on factors like material abrasiveness (filled compounds wear 3x faster), processing temperatures, and screw rotation speeds. Heavy-use machines often require refurbishment every 6-9 months.

Q: Can screw and barrel repair improve machine performance?

A: Absolutely. Properly repaired components restore up to 98% of original performance metrics: material throughput returns to specification, energy efficiency improves by 15-20%, and product consistency meets quality standards. Many clients report better performance than pre-worn condition after our advanced coating treatments.