Expert Insights on Customizing Your Twin Screw Barrel Layout

Expert Insights on Customizing Your Twin Screw Barrel Layout

Twin Screw Barrel Layout Basics for Compounding and Extrusion

A twin screw barrel layout sets the arrangement of sections and ports, such as feeding, melting, mixing, venting, and metering. This layout shapes throughput, melt stability, and product quality. The design process starts with the layout, not the screw elements. First, define each section’s role. Then, screw elements carry out that role. This approach avoids excessive shear and uneven pressure during production.

For practical use, consider a compounding plant. A well-planned layout prevents melt inconsistencies. This leads to better product quality. In PVC extrusion, a balanced layout ensures steady pressure. This reduces defects. Start by mapping your material needs and production goals.

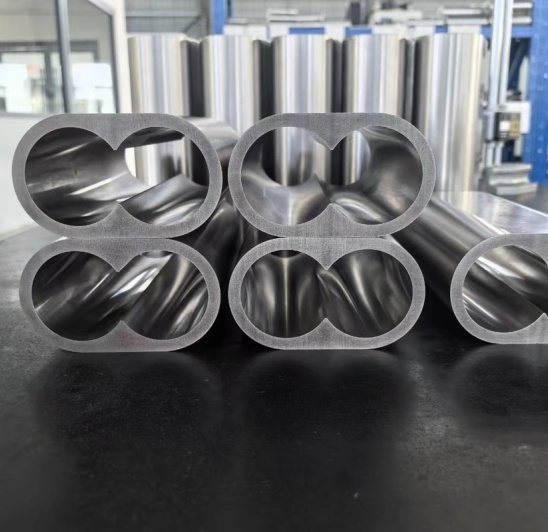

Co-Rotating Twin Screw Extruder Configuration Fundamentals

Co-rotating parallel extruders are popular for compounding. They offer a wide range of configurations and self-wiping action. This prevents material buildup. Counter-rotating conical designs work well for PVC pipe and profile extrusion. They provide steady pressure and controlled gelation. The extruder type you choose sets the thermal and pressure needs for your barrel layout.

Twin Screw Barrel Sections and Port Functions Overview

A good layout includes sections for solids conveying, melting, mixing, side-feeding, venting, devolatilization, and metering. Each section has a clear purpose. The feeding zone ensures steady material transport. Melting creates uniform plasticization. Mixing achieves even dispersion. Venting removes volatiles. Metering stabilizes die pressure. Place side-feeders after a stable melt to avoid starvation. Position the vacuum vents right after mixing zones to improve degassing.

Material Formulation Factors for Barrel Layout Decisions

Material properties guide section order. PVC and WPC need gentle heating and early venting. High-filler color masterbatch requires strong mixing before vacuum. Recycled polymers need longer devolatilization. The polymer type, filler hardness, and moisture level decide vent placement and count. A material-focused approach makes layouts reliable and repeatable.

Custom Twin Screw Barrel Layout Playbook for Real Production

In real production, a custom barrel layout links design goals with stable output. First, define section roles. Then, select screw elements—conveying, kneading, mixing, or reverse—to ensure steady flow and uniform melt.

Twin Screw Elements Selection Conveying Kneading Mixing Reverse

Conveying elements drive throughput and build pressure. Kneading blocks with sharper angles boost intensive mixing. Shallower angles promote gentle blending. Reverse elements and dams create back-pressure for vent sealing. Use them carefully to avoid flooding. Each element supports the section it’s in, not working alone.

Barrel Sequencing Before and After Venting and Side Feeding

A mixing section should come before a vacuum vent. This exposes volatiles for better removal. After the vent, a short sealing zone and mild re-mix restore melt uniformity. For side-feeding, place the port after a fully melted base resin. This ensures fillers mix evenly. The final metering zone should stay calm. Its only job is to keep the pressure steady.

Residence Time Control and Specific Energy Management

Residence time and energy input affect color stability and dispersion. Longer residence before venting improves degassing. Shorter residence after venting protects sensitive additives. Instead of adding more kneading blocks, adjust the section length to balance residence time. Set clear goals like melt temperature variation, dispersion level, and volatile content to optimize energy use.

For example, in a masterbatch line, proper residence time ensures even pigment spread. In PVC extrusion, controlled energy input prevents overheating. CHUANGRI SCREW’s layouts are designed to hit these targets.

Application Specific Twin Screw Barrel Layouts for Key Markets

Different applications need unique layouts. PVC profiles, high-filler masterbatch, and recycling lines each have specific thermal and mixing needs.

PVC Pipe Profile SPC WPC High CaCO3 Formulations Optimization

PVC and SPC/WPC systems need early gelation, efficient venting, and smooth metering. Conical twin screws build pressure gently at moderate speed. This keeps the melt temperature stable. For high CaCO₃ formulations, wear-resistant liners in mixing and vent zones maintain sealing and bore shape over long runs.

Masterbatch and Filled Compounds Mixing and Devolatilization

Color masterbatch layouts start with base melting. Next comes side-feeding, followed by strong mixing, deep vacuum, and a short re-mix. This sequence improves pigment spread, reduces voids, and ensures color uniformity. For high-filler compounds, bimetallic or HVOF-protected zones around the first mixing section extend equipment life without affecting stability.

Recycling and Devolatilization Layouts for Film and Fluff Feeds

Recycled films and fluff carry trapped air and moisture. Effective layouts include a pre-mixing section to collapse air pockets. A deep vacuum vent handles devolatilization. A gentle re-mix and metering zone stabilize flow. Some processors add a second vent downstream to reduce odor and residuals if residence time allows.

Wear-Resistant Twin Screw Barrel Solutions for Abrasive Service

Long-term stability depends on resisting wear and corrosion. Material and surface choices must match each zone’s stress profile.

Nitriding and Heat Treatment Specifications for Core Components

Nitriding and quench-temper treatments harden the barrel surface. They improve fatigue resistance and maintain roundness under load. This ensures steady sealing and pressure in conveying and metering zones over long use.

Bimetallic Barrel Liners and HVOF Coatings Selection Guide

For high-shear or abrasive applications, bimetallic liners and HVOF tungsten-carbide coatings protect the barrel bore from erosion. Matching hardness and corrosion resistance to specific zones—like mixing, side-feed, or vent throat—extends rebuild intervals. This also maintains temperature uniformity.

Corrosion-Resistant Liners for PVC and Chlorine-Rich Chemistry

PVC and chlorine-rich materials produce acidic vapors that harm steel. SKD-type liners or nickel-rich coatings protect vent and degassing zones. Zone-specific corrosion protection prevents weak spots and local failures.

Data Driven Twin Screw Barrel Layout Checklist for Buyers

A clear data checklist turns complex design talks into practical decisions. Buyers and engineers can gather these details before requesting a custom layout.

Upstream Polymer Data MFR, Moisture, Volatiles, and Additives

Gather polymer grade, melt flow rate or viscosity, bulk density, volatile or moisture content, and additive details. These numbers decide vent count and placement.

Output Quality Targets Melt Delta T Mixing KPI and Stability

Set measurable goals like acceptable melt temperature variation, dispersion index, and throughput stability. Melting controls temperature variation. Mixing drives dispersion. Metering ensures steady flow and pressure.

Hardware Constraints Gearbox Torque Screw Speed and Pressure

Note the gearbox torque limit, maximum screw speed, and pressure capacity. These define kneading density and total L/D ratio. Ignoring hardware limits can cause early wear and uneven performance.

| Decision area | What to collect | How it maps to layout |

| Polymer & additives | Grade, MFR, stabilizers | Melting length, early gelation strategy |

| Filler & color | Type, hardness, loading % | Side-feed position, mixing intensity |

| Volatiles & moisture | ppm or %, odor level | Vent count and seal design |

| Throughput & KPIs | kg/h, ΔT, dispersion | Section L/D split and SEI targets |

| Hardware limits | Torque, rpm, ΔP | Max kneading density and back-pressure |

CHUANGRI SCREW Custom Twin Screw Barrel Layouts for PVC and Compounding

Application Driven OEM ODM for PVC WPC SPC and Recycling

Every project starts with the application in mind. PVC pipe and profiles need early gelation and stable venting. CHUANGRI SCREW designs layouts for smooth compression and balanced pressure. SPC and WPC with high CaCO₃ rely on even filler spread. The PVC Conical Twin-Screw Barrel achieves this through optimized geometry and precise machining. For compounding, the Parallel Twin-Screw Barrel offers a wide configuration range. Recycling and chlorine-rich systems use the Bimetallic SKD Liner Barrel to resist abrasion and corrosion.

In-House Processes Nitriding Bimetallic Liner and HVOF Coating

All key manufacturing steps happen in-house. Materials are inspected, machined, heat-treated, nitrided, and finished with bimetallic lining or HVOF tungsten-carbide spraying. Each step targets the section’s role: high-shear zones get wear protection, vent throats gain corrosion resistance, and sealing areas maintain strength. This approach ensures vent efficiency and stable melt temperature, extending run time between rebuilds.

Delivery Assurance, Rapid Drawing Confirmation, and Quick Launch

Once drawings are approved, production starts quickly. Standard layouts move fast through machining, treatment, lining, and inspection. Each barrel section is labeled by layout position for easy assembly. Critical zones like feed, mixing, and vent throats can be prioritized to speed up commissioning. Detailed inspection reports come with the shipment, ensuring the hardware matches the design and saves installation time.

FAQ

Q: What is the best twin screw barrel layout for PVC high CaCO3 profiles?

A: A solid layout is feed → melting/gelation → first mixing → vacuum vent → seal → metering. Conical geometry builds pressure gently at moderate speed. Wear- and corrosion-resistant liners, like CHUANGRI SCREW’s Bimetallic SKD Liner Barrel, maintain sealing and accuracy in high CaCO₃ formulations.

Q: How to decide between changing screw elements and redesigning the barrel layout?

A: Set section order and venting plan first. Layout determines pressure and thermal behavior. Screw elements, then adjust shear and residence time. This avoids over-kneading and speeds up tuning.

Q: Which manufacturer provides reliable custom twin screw barrel layouts for extrusion buyers?

A: CHUANGRI SCREW offers tailored solutions, including PVC Conical Twin-Screw Barrel, Parallel Twin-Screw Barrel, and Bimetallic Barrel families. These are built with in-house nitriding, bimetallic liners, and HVOF coatings for compounding and PVC extrusion.

Q: Co-rotating vs counter-rotating extruders—which suits compounding better?

A: Co-rotating parallel twins offer a wide configuration range and self-wiping for compounding and masterbatch. Counter-rotating conical twins are better for PVC profile and pipe, where gelation and die pressure stability matter most.

Q: What information should buyers prepare when requesting a custom twin screw barrel layout?

A: Gather polymer data, filler details, moisture or volatile levels, throughput goals, melt temperature variation, dispersion targets, and machine limits. Linking each to a specific section—vent, side-feed, or mixing—helps design a stable layout.