Automatic Screw Feeding: Key Considerations for Optimal Performance

Automatic Screw Feeding: Key Considerations for Optimal Performance

What is Automatic Screw Feeding and Why Does It Matter?

The Importance of Automation in Screw Feeding

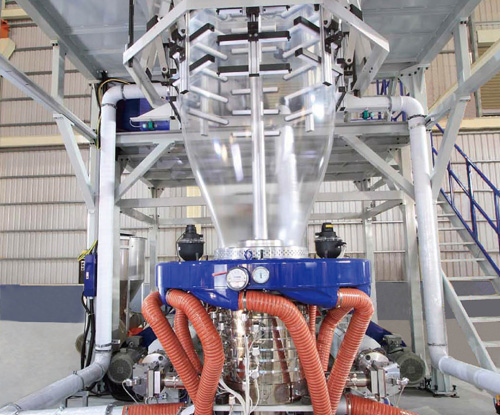

The addition of automated screw feeding has emerged as an element for companies wanting to improve efficiency and accuracy in operations. Screw feeding systems aim to make it simpler to deliver screws to assembly points by eliminating the human element and lessening the time taken on repetitive activities. Not only does this improve production, but it also reduces human error immensely for a quality of output consistent throughout. CHUANGRI SCREW underscores the precision of the screws tailored to meet needs that enhance productivity while minimizing wear and tear. These advancements in automation respond to the escalating demand for efficiency across diverse manufacturing domains.

How Auto Screw Feeders Enhance Efficiency

Auto screw feeders enhance productivity by automating the process of delivering screws, conserving time for manual alignment and handling. They deliver screws quickly and precisely to the fastening point, conserving time and enhancing precision. This leads to enhanced productivity, consistent quality, and reduced labor costs in production lines.

How to Choose the Right Auto Screw Feeder for Your Needs?

Factors to Consider When Selecting an Automatic Screw Feeder

Compatibility with Different Screw Types and Sizes

When selecting a screw feeder for your use, compatibility should be among the top considerations. It should be able to accommodate types and sizes of screws to fill a range of application requirements. CHUANGRI SCREW provides crafted screws designed for specific production lines. This ensures incorporation with current equipment and boosts efficiency in various manufacturing operations.

Speed and Precision Requirements

Picking a screw feeder is a trade-off between accuracy and speed to meet production objectives efficiently without sacrificing accuracy. When selecting an automatic screw feeder, consider the speed and accuracy that your assembly process requires. High-volume production lines need feeders that can dispense screws quickly without jamming. Precision ensures each screw is placed accurately, reducing errors and improving product quality in automated operations.

Common Challenges in Selection and How to Overcome Them

Choosing the automatic screw feeder can be quite tricky because of the different needs during operations and environmental conditions that come into play. A frequent problem faced is making sure that the feeder system aligns with the equipment in use. This can be resolved by conducting evaluations and seeking advice from professionals. CHUANGRI SCREW’s expert team offers assistance ranging from designing recommendations to post-purchase support to ensure smooth execution. Another issue involves finding a balance between cost and quality. Opting for a system may mean higher initial expenses but leads to lasting savings by reducing maintenance and downtimes in the long run.

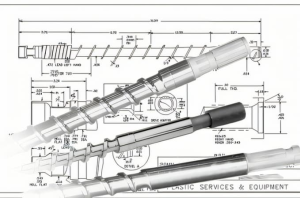

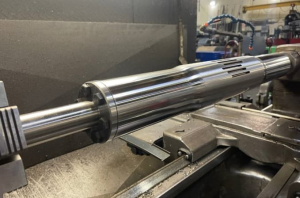

Our screws are made with high-quality materials such as 38CrMoAlS and CPM alloys to provide durability against wear and corrosion for a longer lifespan of use. We offer products for various industrial purposes, like injection molding machines and extrusion processes whether you need nitrided surfaces or bimetallic processing options.

Our screws are made with high-quality materials such as 38CrMoAlS and CPM alloys to provide durability against wear and corrosion for a longer lifespan of use. We offer products for various industrial purposes, like injection molding machines and extrusion processes whether you need nitrided surfaces or bimetallic processing options.

We also offer solutions designed to meet your specific needs. Our team works closely with clients from CAD design to the stages of production to enhance performance in all applications. By focusing on innovation and ensuring customer satisfaction, CHUANGRI SCREW continues to be your partner in improving productivity with top-notch automatic screw-feeding solutions.

What Are the Common Issues in Automatic Screw Feeding Systems?

Troubleshooting Misaligned or Jammed Screws

Problems usually arise with stuck screws in automatic screw-feeding systems that can result in production downtime and create extensive downtime. The major reasons for such problems usually involve size and shape differences as well as incorrect system settings or feeder component wear.

To tackle these obstacles effectively and keep things running smoothly with the feeder system in place requires upkeep and checks, the essential steps include verifying that the screws utilized align with the feeder’s parameters. CHUANGRI SCREW provides specially designed screws to cater to diverse industrial requirements for easy integration into different automatic screw-feeding systems. Moreover, the utilization of quality materials for screws and other components of feeders can provide durability with minimized possibilities of clogging or misalignments. Some of the advanced features such as sensors can be incorporated in automatic screw feeders for detecting and rectifying misalignments in real time. This proactive method does away with the need for adjustments and improves overall system reliability.

To tackle these obstacles effectively and keep things running smoothly with the feeder system in place requires upkeep and checks, the essential steps include verifying that the screws utilized align with the feeder’s parameters. CHUANGRI SCREW provides specially designed screws to cater to diverse industrial requirements for easy integration into different automatic screw-feeding systems. Moreover, the utilization of quality materials for screws and other components of feeders can provide durability with minimized possibilities of clogging or misalignments. Some of the advanced features such as sensors can be incorporated in automatic screw feeders for detecting and rectifying misalignments in real time. This proactive method does away with the need for adjustments and improves overall system reliability.

Ensuring Consistency in High-Volume Operations

In manufacturing plants like high-speed production facilities, consistency is paramount. Automated screw feeding systems need to release screws from time to time and in an accurate measure without sacrificing speed or accuracy. Finding the balance, however, is not always simple because there are complex difficulties like wear on feeder components differences in the screw quality or other environmental conditions like temperature and humidity.

CHUANGRI SCREW’s engineering knowledge guarantees that our screws are of quality even in unfavorable conditions with rigorous test processes, so that each piece is up to international standards for durability and efficiency critical to large-scale operations where even the smallest deviations can cause drastic inefficiencies.

One other important factor involves incorporating automation technologies into screw-feeding systems. The inclusion of features like customizable controls and live monitoring enables manufacturers to promptly adjust to evolving production needs.

How Can CHUANGRI SCREW Help Optimize Your Automatic Screw Feeding Process?

Our Advanced Technology for Precision and Reliability

At CHUANGRI SCREW, we recognize the importance of precision and dependability in screw-feeding systems. Our technology guarantees that each screw is carefully designed to enhance performance in different uses. Utilizing top-grade materials such as 38CrMoAlA and CPM alloys, our screws guarantee wear resistance and corrosion resistance alongside long life. This increased durability guarantees performance even in harsh environments.

Customizable Solutions for Various Applications

Our expertise shines through in our knack for offering solutions that cater to your unique requirements perfectly matched to your individual needs. Whether you need screws for injection molding machines or extrusion processes. We’ve got you covered! Our team of specialists is knowledgeable in creating components that perfectly complement your systems to deliver world-class outcomes. With the latest design software, like AutoCAD and Solidworks, our research and development department can design optimized solutions to enhance efficiency and productivity. From screws to optimized solutions for extreme environments, like high-temperature or corrosive environments. We guarantee compatibility with any make or model out there.

High-Speed, Durable, and Easy-to-Maintain Systems

Our items are designed to handle fast-paced tasks effectively while maintaining toughness as a priority focus point. CHUANGRI SCREW’s injection molding and extrusion screws ensure quality in end products along with top-notch performance and lasting durability. The detailed production process involves threading, milling, grinding and polishing to achieve measurements and seamless surfaces. This not only improves the functionality of automated screw-feeding systems but also lessens the need for frequent maintenance.

Unmatched Customer Support and Technical Services

At CHUANGRI SCREW, we prioritize customer satisfaction above all else in our operations. Our services encompass a range of support options aimed at ensuring the smooth setup and functioning of your automatic screw feed systems. Our skilled team offers consultations on design makes on-site measurements, handles system adjustments and provides sales support. We also guarantee to address any quality concerns during the warranty period to give our clients peace of mind.

Allow us to assist you in reaching excellence through our cutting-edge technology and unwavering support services!

Frequently Asked Questions about Automatic Screw Feeding

Q: What is an automatic screw feeder?

A: An automatic screw feeder is a machine that supplies and positions screws for fast and precise assembly, improving efficiency in production lines.

Q: Can it handle different screw sizes?

A: Yes, most models support various screw sizes, but you may need to change the rail or bit to match different specifications.

Q: Is it easy to operate and maintain?

A: Automatic screw feeders are user-friendly. Regular cleaning and basic part replacement ensure long-lasting, low-maintenance performance.

Q: How fast can it feed screws?

A: Feeding speed depends on the model, but high-quality feeders can deliver up to 60 screws per minute with consistent accuracy.