Conical Screw Barrel: Essential Maintenance Tips for Long-Term Use

Conical Screw Barrel: Essential Maintenance Tips for Long-Term Use

What Is a Conical Screw Barrel and Why Is It Critical in Plastic Processing?

The Role of the Conical Screw Barrel in Extrusion Machinery

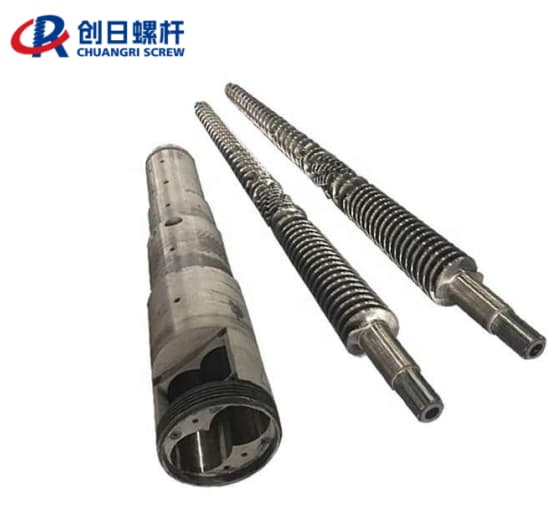

A conical screw barrel is a nifty piece of kit in twin-screw extruders. It’s a big player in the plastics world. This gem melts, mixes, and pushes plastic materials through a clever combo of mechanical and heat-driven steps.

The screw handles three key jobs: moving solids, melting them down, and pumping out the gooey result. In conical twin-screw extruders, the screws sit at an angle, getting closer toward the exit. This setup amps up material squishing and mixing, especially for tricky plastics like PVC or ones packed with fillers.

Key Components and Their Functions in a Conical Screw Barrel

A conical screw barrel has a few star players: twin screws, barrel housing, feed section, compression zone, and metering zone. Each does its part in turning raw plastic into finished goods.

The feed section grabs material and keeps it flowing steadily. The compression zone melts and blends the plastic under pressure. The metering zone smooths out the flow before it hits the mold. Barrels are key components in injection molding and extrusion processes. They hold everything together and keep temperatures just right along the screw’s path.

How the Design of a Conical Screw Barrel Enhances Performance

The conical design is a total game-changer compared to parallel setups. Its shrinking diameter from start to finish squeezes material gently without too much stress.

This design shines for making WPC boards, doors, foam boards, SPC flooring, and all PVC products. It mixes and melts like a champ, even with recycled plastics or high calcium carbonate fillers. In setups with any calcium carbonate ratio, we’ve stretched screw lifespan by over 30%.

How Can Regular Maintenance Extend the Life of Your Conical Screw Barrel?

Daily and Weekly Inspection Checkpoints for Optimal Function

Keeping your conical screw barrel in top shape needs regular checkups. Every day, peek at melt pressure, make sure temperatures stay even across zones, and listen for weird shakes or noises.

Weekly, get up close with tools like borescopes to spot wear on screw flights or barrel walls. Scratches or odd colors? Those could mean trouble’s brewing early.

Lubrication Techniques That Prevent Wear and Tear

Good lubrication keeps friction low between moving parts. Slather high-temperature-resistant greases on bearings and gear reducers tied to screw spinning.

Don’t go overboard with lube—it can cause heat buildup or mess up your plastics. Stick with synthetic lubricants made for polymer processing, as makers suggest.

Cleaning Practices That Protect Internal Surfaces from Damage

Cleaning’s a must during shutdowns or material switches to avoid gunk buildup. Use purging compounds tailored to your plastic type to clear out leftovers without scratching bimetallic linings or nitrided surfaces.

Skip metal tools that could nick the barrel’s insides. Gentle cleaning keeps things smooth and safe.

What Are Common Problems with Conical Screw Barrels and How Can You Avoid Them?

Early Signs of Wear, Corrosion, or Misalignment

Wear shows up as thinning screw flights or grooves inside the barrel. Corrosion might look like pitting from harsh additives like flame retardants or acidic fillers.

Misalignment comes from sloppy setup or heat expansion mismatches. Watch for uneven output or a motor working too hard. SKD inner lining technology, slotted in where needed, slows down wear and keeps things running longer.

Causes of Decreased Output or Product Quality in Operation

Low output is often tied to worn screws that can’t push material well. Spotty product quality—like uneven melt flow—can come from wonky heating zones or beat-up mixing parts.

Leftover gunk from old batches, due to lazy cleaning, also messes with quality across runs.

Preventive Measures That Save Time and Replacement Costs

Stick to scheduled maintenance based on running hours, not just fixing stuff when it breaks. Keep spare parts like thermocouples and heaters handy to cut downtime on small fixes.

Using various structural designs for high, medium, or low calcium content keeps performance sharp and extends gear life for your specific materials.

Which Tools and Methods Should You Use for Effective Maintenance of a Conical Screw Barrel?

Recommended Instruments for Measurement and Calibration

Grab precision tools like micrometers, dial gauges, bore gauges, thermographic cameras, and ultrasonic thickness testers. These spot tiny changes that scream wear before things go south.

They help you catch issues early, so you can fix them before a total breakdown.

Proper Handling During Disassembly and Reassembly

Follow OEM guides when taking apart your conical screw barrel. Use heavy-duty lifting gear to avoid dings during removal.

Clean all mating surfaces before putting it back together for perfect alignment. Dab on anti-seize compound to make future maintenance a breeze without stuck threads.

Storage Conditions That Preserve Structural Integrity

Store spare barrels flat on padded racks, away from sun or dampness. Keep humidity under 60% to dodge rust on uncoated surfaces.

Pop desiccant-filled plugs in openings to shield insides from dust or rust during long storage stints.

Why Choose CHUANGRI SCREW for High-Performance Conical Screw Barrels?

Who We Are: Our Dedication to Precision Engineering and Durability

At CHUANGRI SCREW, every screw and barrel is a work of art. Our production pros bring deep know-how and hands-on skills to boost output, cut costs, and keep quality steady across industries.

Our Core Product: Bimetallic and Nitrided Conical Screw Barrels

High Wear Resistance for Long-Term Industrial Use

Our bimetallic and SKD inner lining technology tackles virgin and recycled materials like champs. They stand up to abrasive stuff like high-filler WPC or PVC-C blends.

Tailored Designs Compatible with Twin-Screw Extruders

We match top global models with sizes like SJZ 45/90, SJZ 55/110, SJZ 65/132, SJZ 80/156, and SJZ 92/188, custom-fit to your needs.

Precision Machining Ensuring Tight Tolerances

Full CNC machining ensures dead-on straightness between screw-barrel pairs. They hum up to 70 rpm without shaky defects. Computerized processing is a perfect fit for better output and quality.

Anti-Corrosion Coatings Suitable for PVC, PE, and PP Materials

Nitriding and ceramic coatings fend off corrosive agents in halogenated plastics. Technology Processing: Nitriding, Bimetallic keeps things tough and reliable.

Quality Control: In-House Testing, Heat Treatment, and Surface Finishing

We run tight quality checks from picking steel to heat treatment and final polishing. Every step ensures our gear lasts under non-stop industrial use.

Customer Support: Technical Consultation, Installation Guidance, After-Sales Service

We’ve got your back with pre-sale design tips, expert setup help, and long-term after-sales support. Our team keeps your equipment delivering value for its whole life.

FAQ

Q: What is a conical screw barrel used for?

A: It’s used in twin-screw extruders to process plastics like PVC into pipes, boards, or flooring, melting and mixing efficiently thanks to its tapered shape.

Q: How often should I inspect my conical screw barrel?

A: Do quick daily checks and detailed weekly ones with gauges or borescopes. Bump it up if you’re using abrasive materials.

Q: What causes premature wear in conical screw barrels?

A: Bad lube habits, mismatched materials like high fillers, or sloppy cleaning that lets gunk build up can wear it out fast.

Q: Can I use recycled plastics with my existing conical screw barrel?

A: Yup, if it’s got bimetallic linings. Some designs handle up to 300% calcium carbonate if set up right.

Q: What’s the difference between nitrided vs bimetallic barrels?

A: Nitrided barrels get surface hardening via gas treatment. Bimetallic ones have an alloy layer inside for extra toughness against abrasion and corrosion—perfect for tough resins.