Exploring Auto Feed Screw Attachment for Drills in Innovative Ways

Exploring Auto Feed Screw Attachment for Drills in Innovative Ways

In today’s busy industrial world, quick work and high output are key. Auto-feed screw attachments for drills are a big help in fields like construction and manufacturing. These tools make screw driving quick and easy by feeding screws on their own. This blog looks at how auto-feed screw attachments have changed, their new uses, and the benefits of adding them to your work. It focuses on solutions from CHUANGRI SCREW.

Introduction to Auto Feed Screw Attachments

Auto-feed screw attachments are changing how industries do assembly tasks. In the past, putting screws into a drill by hand took time and effort. Now, auto-feed attachments make this job automatic. They improve work speed and cut down on mistakes. In 2025, as industries try to work quicker and spend less, these tools are in high demand. They are needed for fields like construction, manufacturing, and furniture assembly that drive lots of screws.

How Auto Feed Screw Attachments Work and Their Key Advantages

Auto-feed screw tips are smart accessories that can be mounted over a wide range of drills and drivers and immediately turn them into automatic, high-speed screwdrivers. The systems use a magazine-type strip, which is capable of holding dozens of screws at the same time, automatically feeding the screws forward after each is screwed. It prevents one from having to manually choose and position every screw, which not only hastens the work but also minimizes hand, wrist, and back strain—especially for long shifts or overhead work. They’re perfect for repetitive work like decking, drywall, or subflooring. With consistent spacing and depth of screws, they also improve precision and overall finish. Some advice has adjustable depth settings and instant feed capabilities, making them even more productive on fast-paced job sites. In construction, renovation, or production-line environments, an auto-feed screw attachment makes the most of your time, energy, and resources, delivering cleaner, faster work with less effort.

The main benefits of auto-feed screw attachments are:

- Quick Work: These attachments let workers drive screws much quicker than by hand. They are great for big projects like drywall or decking that need many screws.

- Even Results: The automatic feed makes sure screws go in at the right depth every time. This lowers mistakes and keeps the finished product even.

- Less Tiredness: Feeding screws by hand can tire workers out, especially over long hours. Auto-feed attachments make the job easier, so workers can focus on other tasks.

- Money Savings: These tools cut labor costs and speed up work. This helps businesses get a better return on their investment.

- Safer Work: Fewer hand tasks mean fewer chances for injuries. Auto-feed attachments make the workplace safer.

Choosing the Right Auto Feed Screw Attachment: Key Considerations

Picking the right auto-feed screw attachment is important to improve work speed and quality. The right tool can make a big difference in how quickly and well your projects go.

- Works with Top Drill Brands: Choose an attachment that fits your drill brand, like Makita, DeWalt, and Bosch. This makes it easy to work with your current tools.

- Handles Different Screws: Different jobs need different screws. Your attachment must handle various screw sizes and types. Our attachments are flexible and work for many industries and tasks.

- Depth Control and Anti-Jam Features: Exact screw driving needs features like depth control and torque adjustment. These ensure screws go in at the right depth and force. Anti-jam systems keep the tool running smoothly without clogs, boosting work speed.

Innovative Applications of Auto Feed Screw Attachments in 2025

As industries grow, auto-feed screw attachments are used in new ways. They are not just for one or two tasks anymore. They work in many fields that need quick and exact screw driving.

- Construction and Drywall: Auto feed attachments are common in construction, especially for drywall. They drive screws quicker and more accurately. This makes wall panel installation faster and better.

- Furniture Assembly: In furniture making, especially for flat-pack items, these attachments speed up assembly. They drive screws evenly and strongly, making products last longer and reducing errors.

- Automotive Manufacturing: The automotive field needs exact assembly. Auto-feed attachments help by feeding screws automatically in assembly lines. This makes production quicker and more consistent.

- Packaging and Production: These attachments are used in packaging and other production lines that work with screws often. They help keep output high while staying safe and consistent.

CHUANGRI SCREW: Providing Tailored Auto Feed Screw Solutions

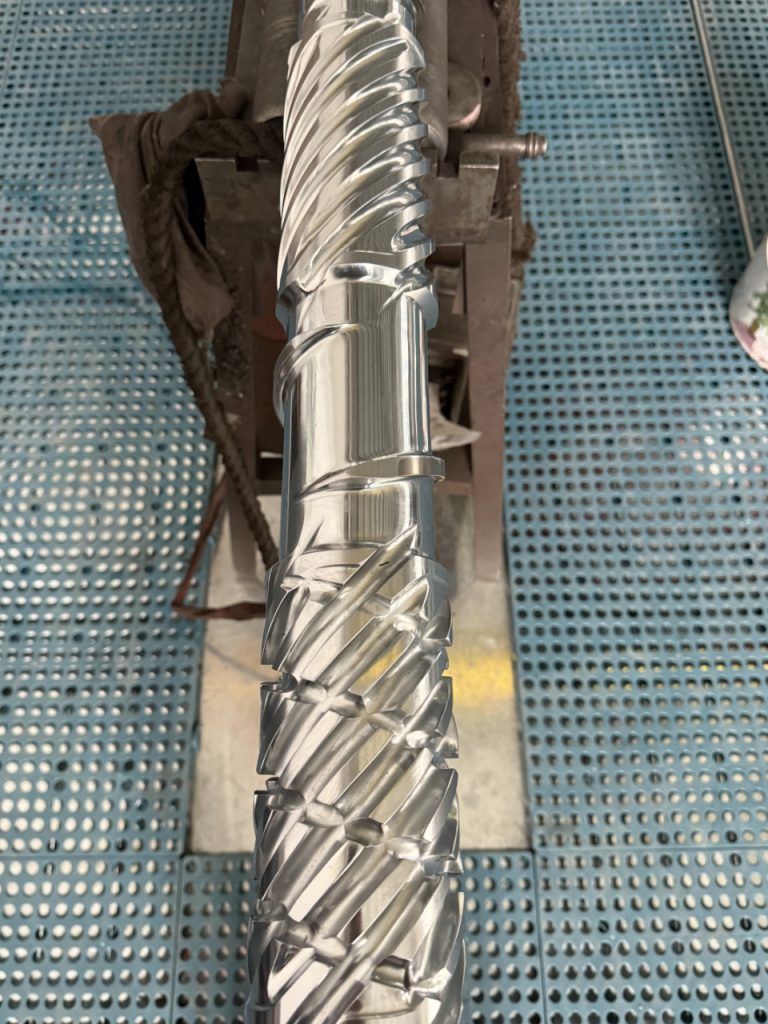

CHUANGRI SCREW has been a leader in screw and barrel solutions since 1990. We make high-precision screws, barrels, and accessories for industries like plastics, automotive, and construction. We know the need for automatic screw-feeding tools is growing. Our team designs products to meet the needs of industries that drive lots of screws with precision.

Key Benefits of CHUANGRI SCREW Products:

- Custom Options: We make screw and barrel designs that fit each client’s needs. Whether for construction or manufacturing, our solutions match your exact requirements.

- Strong and Long-Lasting: Our products use high-quality materials for great wear resistance, even in tough conditions. Our auto-feed attachments last long without needing frequent replacements.

- Better Work Speed: CHUANGRI SCREW’s products are built to speed up production. Our auto-feed solutions cut labor costs and make work quicker.

- Trusted Worldwide: With over 30 years of experience and sales in more than 50 countries, CHUANGRI SCREW is a trusted name. Our products meet global standards through strict quality checks.

FAQ

Q: What is an auto-feed screw attachment and how does it work?

A: An auto-feed screw attachment is a mechanism that will automatically feed screws into a drill or driver. It consists of a magazine-type system to hold a large amount of screws and feeds them one at a time as each one is driven.

Q: Will auto-feed screw attachments work on all drills?

A: The majority of the attachments work with many drills, especially those of Makita, DeWalt, and Bosch. Always examine the attachments for compatibility with your drill model.

Q: Can auto-feed screw attachments be used for heavy industrial applications?

A: Yes. They work well for big projects like construction, car manufacturing, and furniture construction. They load the screws in an efficient and precise manner.

Q: How do auto-feed screw attachments improve productivity?

A: They auto-feed screws, so laborers drive screws more rapidly and precisely. This saves on labor and boosts output.

Q: What kinds of materials will auto-feed screw attachments handle?

A: They handle materials like wood, drywall, plastic, and metal. They’re convenient for a variety of industrial uses.