How to Choose the Right Co-Extruder Screw and Barrel for Your Needs

How to Choose the Right Co-Extruder Screw and Barrel for Your Needs

What Factors Should You Consider When Selecting an Extruder Screw and Barrel?

Key Material Properties to Match with Your Application

The choice of barrel and extruder screw is key to your productivity. When choosing, take the properties of both parts into account. Different plastics such as PVC, HDPE and ABS have processing requirements that necessitate certain compositions of materials.

The choice of barrel and extruder screw is key to your productivity. When choosing, take the properties of both parts into account. Different plastics such as PVC, HDPE and ABS have processing requirements that necessitate certain compositions of materials.

In addition, if you are working with materials having high content or difficult additives choosing bimetallic barrels and screws can greatly improve their longevity from wear and tear issues. CHUANGRI SCREW’s bimetallic barrels are created with carbide particles uniformly distributed in a nickel alloy structure providing top-notch protection against corrosion and ensuring a longer lifespan.

How Processing Requirements Influence Your Choice

Your extrusion system’s operational requirements are important when choosing the extruder screw and barrel parts. For example, when handling temperatures or corrosive materials, the use of nitrided or coated screws might be necessary. CHUANGRI SCREW utilizes advanced nitriding methods to manufacture screws that provide heat resistance and longevity. Likewise for processes demanding production rates using screws with enhanced compression ratios could be advantageous.

The Importance of Wear Resistance and Corrosion Protection

Choosing extruder parts requires attention to durability against wear and corrosion risks over time from abrasive materials that can damage the equipment and disrupt operations unexpectedly. CHUANGRI SCREW utilizes methods like HVOF tungsten carbide coatings to enhance longevity and ensure consistent product quality by reducing material wear during processing tasks.

Why Does Design Matter in Extruder Screws and Barrels?

The Role of Screw Geometry in Performance

The shape of a screw in an extruder helps make it efficient. The design of the screw is important in helping materials melt well and be blended and transferred effectively during the extrusion process.

Single vs. Twin-Screw Configurations

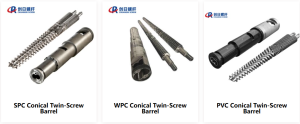

Single screw extruders work well for tasks with uniform materials while twin screw setups excel in mixing and are more suitable for intricate formulations or materials that need thorough blending. CHUANGRI SCREW offers twin screw barrels and conical twin screw barrels designed to meet the needs of specific applications such as producing PVC pipes or manufacturing WPC boards.

Single screw extruders work well for tasks with uniform materials while twin screw setups excel in mixing and are more suitable for intricate formulations or materials that need thorough blending. CHUANGRI SCREW offers twin screw barrels and conical twin screw barrels designed to meet the needs of specific applications such as producing PVC pipes or manufacturing WPC boards.

How Barrel Design Impacts Extrusion Efficiency

The barrel structure is included in ensuring maximum efficiency in the process of extruding with factors, including temperature control mechanisms and heat transfer characteristics affecting material uniformity favorably.

Maintaining a barrel temperature is essential for uniform melting of the material and avoiding degradation issues. CHUANGRI SCREW barrels feature inner linings manufactured with SKR technology to increase heat dissipation without compromising structural integrity. This is especially useful in processes such as blown film extrusion where temperature control of melting is essential.

How Can Proper Maintenance Extend the Life of Your Extruder Screw and Barrel?

Common Causes of Wear and Tear

Operation of extruder barrels and screws under conditions may lead to wear and tear issues over a long period due to reasons like abrasive materials and high temperatures that compromise the component’s integrity and corrosive chemicals that speed up degradation processes, especially in applications for PVC or other chemicals.

It is also possible to wear out the equipment due to poor installation or maintenance procedures. The screw must be aligned correctly in the barrel to prevent wear patterns from forming. Inadequate lubrication and cleaning methods can worsen friction between the parts well.

Maintenance Tips to Maximize Durability

Cleaning Best Practices for Optimal Performance

You will need to clean your extruder screw and barrel regularly so that they continue to function and for a longer period. Do not forget to remove any leftover material on the two parts completely after each production run. This prevents material accumulation that will cause clogging or uneven melting in runs.

CHUANGRI SCREW advises the use of cleaning agents tailored to your materials to prevent chemical reactions that might hurt the surface of the barrel or screw. Use caution in the use of cleaning tools to prevent causing dents or scratches. In cases where residues are formed, it is advisable to use purging compounds that are meant for extrusion systems.

Recognizing Signs of Damage Early

Detect problems early to avoid repairs or replacements later on by regularly checking your extruder screw and barrel for signs, like uneven wear on the screw flights or discoloration from overheating.

Why Choose CHUANGRI SCREW for Your Compound Extruder Screw Barrel Needs?

Our Expertise in Manufacturing High-Quality Extruder Components

We have constantly adapted to the industry’s changing needs over the years. With a wealth of experience spanning three decades, we specialize in manufacturing screws and barrels tailored for various extrusion uses. Our facility covers an area of 12,500 meters with over 60 experienced employees and has successfully executed more than 4,600 projects across more than 30 countries where we export our products.

We use state-of-the-art CNC machining tools and modern technologies, such as nitriding and quenching to enhance our screws and barrels with coatings and alloying methods for improved durability and performance standards compliance on all the products we manufacture. Each solution is uniquely crafted to meet your production requirements by our team of engineers who blend expertise with hands-on experience for a personalized touch tailored to your needs.

Features of CHUANGRI SCREW’s Compound Extruder Screw Barrels

Precision Engineering for Superior Performance

Each compound extruder screw barrel we produce is a work of art crafted with expertise and precision in mind. Our parts are designed to improve functions like material transport efficiency and uniform melting and metering. Whether you’re working with PVC pipes or reprocessing pellets for recycling purposes, our screws are tailored to boost efficiency without compromising product quality consistency. We provide top-notch accuracy through cutting-edge machining methods that guarantee tolerances and smooth incorporation into your extrusion setup.

Durable Materials Designed for Long-Term Use

Durability is the foundation of our manufacturing approach. We utilize high-quality materials like 38CrMoAlA and AISI 4140 along with carbide alloys and nickel-rich iron/boron alloys to craft parts that can endure harsh environments. Our bimetal barrels are designed with carbide particles uniformly distributed in a nickel alloy matrix to provide outstanding resistance to wear. Furthermore, the nitriding process we employ improves heat stability and increases the durability of screws by boosting their resistance to wear.

Customization Options Tailored to Specific Applications

At CHUANGRI SCREW, we know that every production line is unique in its way, which is why we provide a wide range of customization choices for our compound extruder screw barrels. Our services include tailored screw designs with compression ratios and the integration of special coatings, such as HVOF tungsten carbide layers. We collaborate very closely with you in developing solutions that are tailor-made to suit you.

When you select CHUANGRI SCREW for your compound extruder screw barrel requirements, you are aligning yourself with a top performer committed to assisting you in attaining production efficiency and cost savings. Our expertise can be invaluable in tuning your extrusion procedures effectively!

Frequently Asked Questions about Compound Extruder Screw Barrel

Q: What is twin screw compounding?

A: Twin screw compounding is a process used to blend and refine various materials, especially thermoplastic composite materials, using a twin-screw extruder.

Q: What is the difference between extrusion and compounding?

A: Compounding is employed to mix a polymer matrix with different additives to achieve a specific material behavior. Extrusion is used to determine the final form of polymers and plastics, from small sample amounts during initial product development through to full-scale manufacturing processes.

Q: What is the difference between a differential screw and a compound screw?

A: Differential screw is a mechanism used gore small precise adjustments between 2 parts and it has 2 screws rotating along the same axis with different pitches that travel in the same directions. The compound screw has 2 screws and has the same axis and different pitches but they travel different directions.