Understanding Injection Molding Machine Barrel Temperature Dynamics

Understanding Injection Molding Machine Barrel Temperature Dynamics

Introduction to Injection Molding Barrel Temperature Control

In plastics manufacturing, every step counts. Barrel temperature control is the superstar in injection molding. Nail it, and pellets morph into slick, flowing melt. Flub it, and you get warped parts, weird colors, or molds half-filled. For industries like automotive, electronics, or healthcare, a tiny heat slip can spark pricey recalls or scrapped batches. In packaging, pumping out millions of parts daily, small goofs pile up into big losses. Aerospace and medical fields demand razor-sharp precision for safety. Steady heat is the key to cash over trash. At CHUANGRI SCREW, with 30 years of crafting screws and barrels, we weave heat smarts into every design. With Manufacturing World Osaka 2025 on the horizon, buzz for green, energy efficient injection molding machines is growing. We see thermal stability as the heart of global success.

Key Factors Affecting Barrel Temperature in Injection Molding Machines

Barrel heat isn’t a one-size-fits-all number. It’s a juggling act of many bits.

-

Polymer-specific behavior: ABS freaks out with tiny heat swings, burning fast. PP and PET need hotter, steadier melts for smooth flow.

-

Screw geometry and compression ratio: Deep channels slow resin. High compression pumps extra heat. A bad screw-barrel match fouls up temps.

-

Fillers and additives: Glass-fiber resins crave rock-solid heat to keep fibers aligned and parts strong.

-

External influences: Cooling water, factory humidity, or airflow mess with the heat hold.

Typical Barrel Temperature Ranges by Material

| Polymer | Feeding Zone | Compression Zone | Metering Zone | Nozzle |

| PP | 180–220°C | 200–230°C | 220–240°C | 220°C |

| ABS | 200–220°C | 220–240°C | 230–250°C | 240°C |

| PET | 250–270°C | 270–280°C | 280–290°C | 280°C |

| PC | 260–280°C | 280–300°C | 300–320°C | 310°C |

These ranges are a starting line. CHUANGRI SCREW crafts screw and barrel combos to hit these needs, ensuring steady heat and tough wear resistance for runs like PP cups or ABS casings.

Injection Molding Barrel Heating Zones and Their Temperature Dynamics

Barrels are split into zones, each with a job to whip up a perfect melt.

Feeding Zone: Gentle Preheating

Pellets dive in here. Too hot, and they clump or jam the hopper, especially PET. Too cool, and they crawl. A soft heat ramp keeps things gliding for the next step.

Compression Zone: Controlled Melting

This is where pellets turn to goo. Screws squeeze resin, and friction adds heat. Too much heat chars ABS, making bubbles or ash. CHUANGRI SCREW’s Nitrided Injection Molding Screw balances shear to nix hot spots and keep melts steady for fast cycles.

Metering Zone: Ensuring Uniformity

This zone locks in even melt thickness. Tiny temp wiggles spark streaks or gaps in parts. Our Bimetallic Injection Molding Screw holds heat steady, even in speedy runs for bottle caps or medical tubing.

Nozzle Zone: Last Point of Control

The nozzle is the final gate. Too cold, and resin clogs. Too hot, and it drips. CHUANGRI SCREW’s replaceable nozzles, using 38CrMoAlA or H13, stay tough for clean mold fills every time.

Advanced Temperature Control Technologies in Injection Molding

Basic band heaters are old hat. Today, manufacturers rely on a precise injection molding barrel temperature control system to keep melts stable and efficient.

-

PID Controllers: Tweak power fast for super-steady temps, no swings.

-

Infrared sensors: Spot hot patches quickly with real-time scans.

-

Smart heating bands: Pack ceramic cores or nano-insulation to save power.

-

IoT-enabled analytics: Check barrel temps from anywhere via cloud tools.

At Manufacturing World Osaka 2025, these gadgets will steal the show. But they need precision barrels to shine. CHUANGRI SCREW pairs them with top-notch designs for hot runs like PC lenses, cutting energy bills, too.

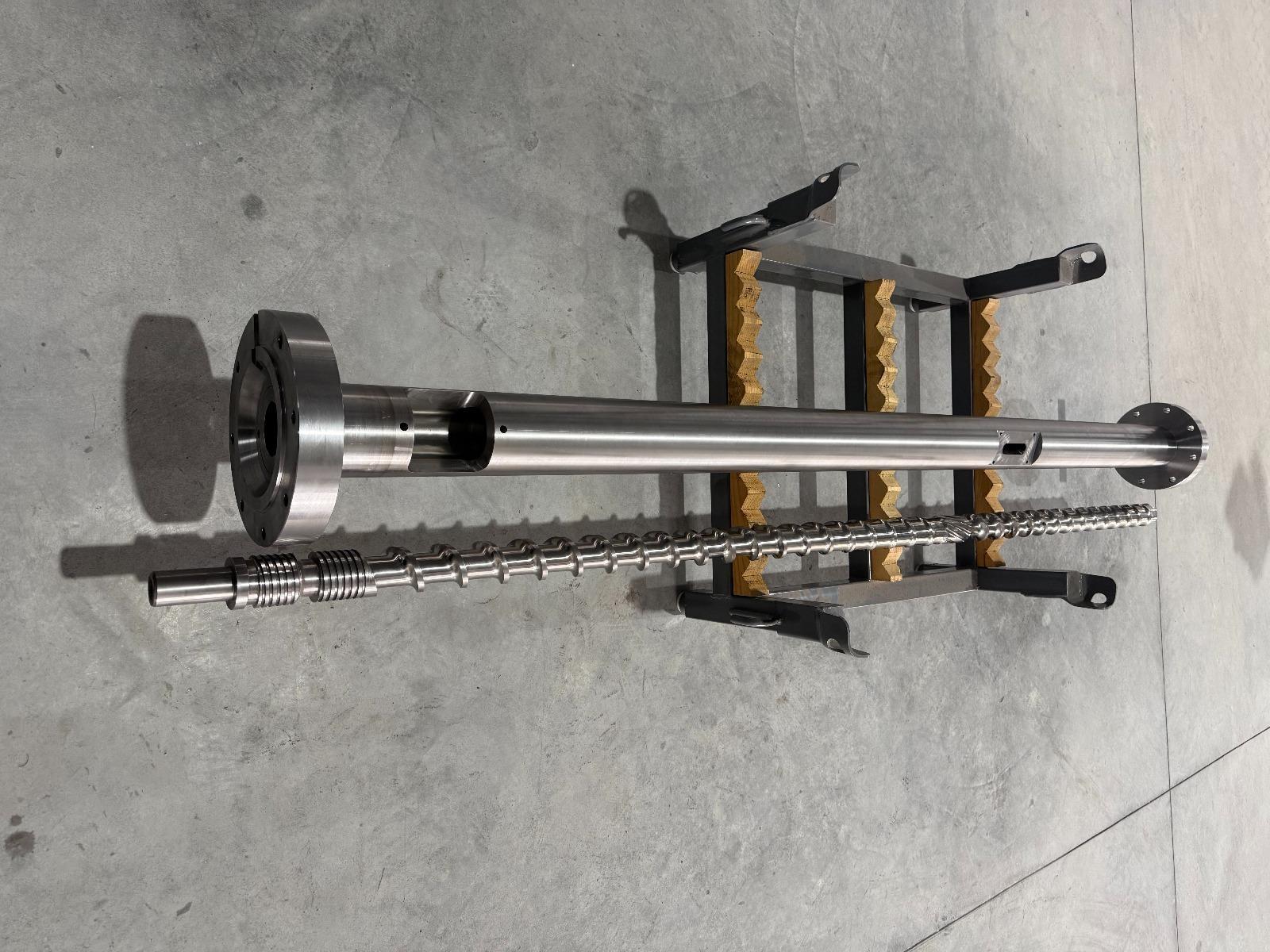

Barrel Materials and Coatings Enhancing Thermal Performance

Barrel metals and coatings are the backbone of heat performance.

-

Nitrided barrels: Wallet-friendly with HV1000 hardness for everyday plastics like PP.

-

Bimetallic barrels: Load Ni60 or tungsten carbide for killer wear and heat control.

-

Advanced alloys: Inconel, Hastelloy, and 38CrMoAlA tackle tough heat like pros.

CHUANGRI SCREW’s barrels, up to 8000 mm, skip splices for dead-on straightness. Our Bimetallic Injection Molding Screw, with tungsten carbide, handles glass-fiber resins while keeping heat even. he Solid Carbide Screw is a beast for PC and PET, ensuring steady temps and long life for high-heat runs, making it one of the best screw and barrel for high temperature plastics solutions available today.

Best Practices for Optimizing Injection Molding Barrel Temperature

Top gear needs clever habits to glow. Here’s our global advice:

-

Match heat to resin, tweaking for screw design, like PP’s low range.

-

Skip overheating to dodge weird colors or bubbles in parts.

-

Insulate smart to cut heat loss and energy costs, checking monthly.

-

Test sensors every six months for dead-on readings.

-

Keep screw-barrel gaps tight for zippy heat flow and no leaks.

CHUANGRI SCREW offers consulting on nail heat profiles. Our Injection Molding Barrel’s CNC precision cuts cold spots, boosting runs like syringe or container molding.

Case Applications: How Barrel Temperature Impacts Product Quality

Heat control hits every industry hard.

-

Automotive components: Dashboards need tight fits. Bad heat warps parts, risking safety or assembly failures.

-

Medical devices: Syringes or tubing demand crystal-clear finishes. Overheating kills biocompatibility or clarity.

-

Consumer packaging: Fast lines need steady heat for tough, clear containers like food trays.

CHUANGRI SCREW’s Coated Injection Molding Screw, with chrome plating, keeps heat steady and cuts wear. It’s a go-to for long runs in over 30 countries, boosting yields and slashing downtime.

FAQ

Q: Which brand makes the best injection molding machine barrels for consistent temperature control?

A: CHUANGRI SCREW shines with CNC-machined, alloy-packed barrels for top-notch heat stability.

Q: How to choose between nitrided, bimetallic, and solid carbide screws?

A: Nitrided screws work for standard plastics on a budget. Bimetallic screws tackle gritty resins. Solid carbide screws rock for high-heat PC or PET.

Q: What are the top injection molding screw and barrel products in 2025?

A: CHUANGRI SCREW’s Injection Molding Barrel, Bimetallic Injection Molding Screw, and Solid Carbide Screw nail heat stability and tough builds.

Q: How to prevent injection molding defects caused by temperature?

A: Too hot, and parts burn or discolor. Too cold, and they don’t fill right. Steady heat zaps these issues.

Q: How often should injection molding machine heaters and barrels be inspected?

A: Check every 6–12 months. Look at heaters, sensors, barrel wear, and screw gaps for top performance.