Why Choose a Reliable Extruder Screw Barrel Manufacturer for Bimetallic Needs

Why Choose a Reliable Extruder Screw Barrel Manufacturer for Bimetallic Needs

In the extrusion industry, how well your equipment performs and how long it lasts are key. Good equipment lets you produce high-quality items while keeping costs low. A vital part of extrusion systems is the extruder screw barrel. This piece moves, melts, and pushes plastic through a mold to shape it. Among the options out there, bimetallic extruder screw barrels stand out. They handle wear better and last longer. This article explains why picking a dependable manufacturer for these barrels is a wise choice. It ensures steady, top-quality results for your extrusion tasks.

Introduction to Bimetallic Extruder Screw Barrels

What Are Bimetallic Screw Barrels?

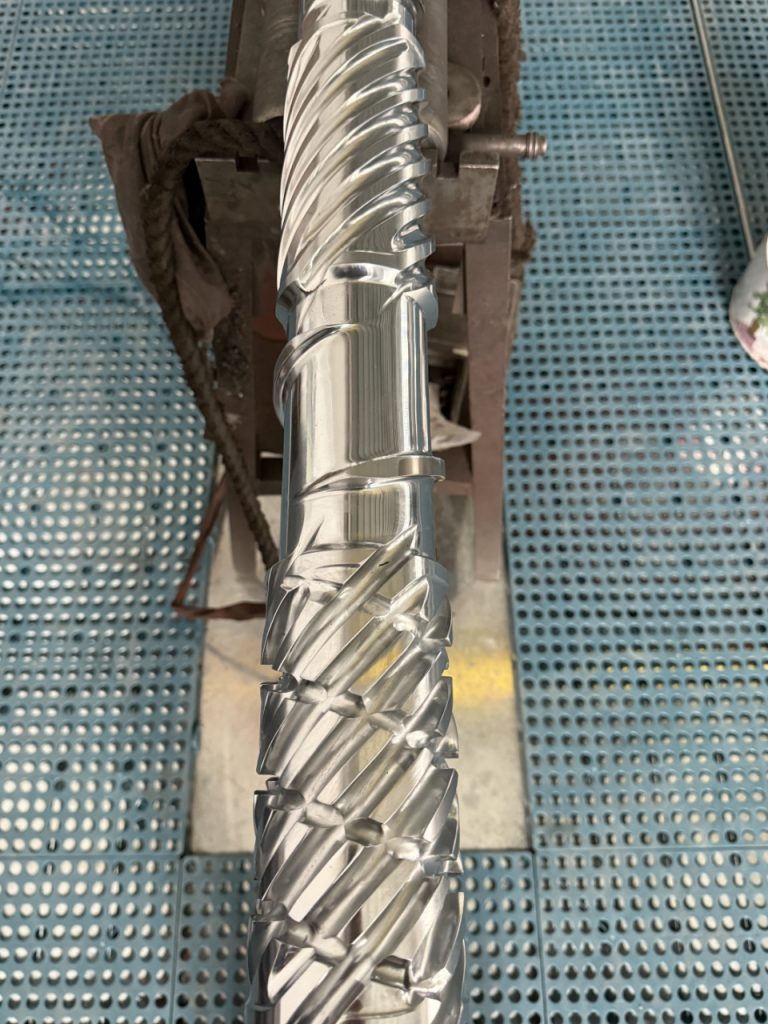

Bimetallic screw barrels are built for tough extrusion jobs. They are made from two materials. The core is strong and keeps everything solid. The outer layer, often made from alloys like nickel, tungsten carbide, or iron-based mixes, adds toughness. This mix helps them take on the hardest processing work.

Importance of Bimetallic Materials in Extrusion Processes

Extrusion is a careful process. You begin by putting raw materials, usually plastic, into an extruder. The machine melts them and forces them through a mold. This creates products like pipes, sheets, or profiles. The process creates a lot of heat and friction. Over time, these can harm regular screw barrels. But for industries using rough or hot materials—like making PVC pipes or blending compounds—bimetallic screw barrels are a great pick.

The outer layer shields the barrel from friction and pressure. This keeps it working smoothly. It also lasts longer. So, you face less downtime and spend less on fixes. Plus, your products stay high quality.

Key Benefits of Choosing a Reliable Manufacturer

Enhanced Durability and Wear Resistance

Bimetallic screw barrels are tough and resist wear well. The outer layer protects the core from damage due to friction, heat, or rough materials. This means they don’t need replacing or fixing often.

At CHUANGRI SCREW, we craft our Bimetallic Extruder Screw Barrels with special coatings. For example, we use tungsten carbide for really hard jobs. This makes them very durable, even in tough settings. Whether you process PVC, HDPE, or filled compounds, our barrels manage it. They keep your production steady with little upkeep.

Superior Corrosion Resistance for Harsh Environments

Extrusion often involves chemicals, water, or other tricky substances. Bimetallic screw barrels fight corrosion better than plain steel ones. This makes them ideal for handling strong chemicals or wet materials. The outer layer works like a shield. It stops rust and wear, so your gear keeps running well.

At CHUANGRI SCREW, our barrels use alloys like nickel-based coatings to tackle corrosion. They hold up against harsh stuff. They suit industries like recycling, chemical processing, or pipe-making, where tough chemicals are common.

Cost-Effectiveness Over Time

Yes, bimetallic screw barrels might cost more at first than regular ones. But they save money over time. They resist wear and corrosion, so they last a long time. You replace them less, and downtime drops. They also make extrusion better. You get more output with less waste, which cuts costs overall.

Factors to Consider When Selecting a Manufacturer

Expertise and Experience in the Industry

When picking a manufacturer for bimetallic screw barrels, go for one with deep industry know-how. A solid manufacturer understands extrusion fully. They can suggest the best choices for your needs.

At CHUANGRI SCREW, we bring over 30 years of experience in making extruder screw barrels. Our team knows extrusion inside out. We can tailor solutions for you. Whether it’s a standard barrel or a custom bimetallic one, we deliver great results.

Quality Assurance and Material Standards

Quality matters a lot when choosing a manufacturer. The materials must meet high industry rules. This ensures they perform well, last long, and stay safe. A good manufacturer uses top materials, tests them thoroughly, and follows global standards.

At CHUANGRI SCREW, we use strong materials like 38CrMoAlA and 42CrMo for our barrels. These provide great strength and wear resistance. We test everything to meet top standards. Our aim is to give you reliable, high-performing equipment.

Customization Capabilities to Meet Specific Needs

Every extrusion task is different. Your screw barrel should fit your setup perfectly. A trusted manufacturer offers custom options. This ensures your bimetallic barrels match your materials, conditions, and products.

At CHUANGRI SCREW, we excel at customizing. We work with you to design barrels that fit your job. Need a special screw shape, coating, or size? We handle it. Your gear will perform at its best.

After-Sales Support and Service

Support after buying is crucial. A good manufacturer provides help with tech advice, upkeep, and repairs. This keeps your equipment running strong for years.

At CHUANGRI SCREW, we offer solid after-sales care care. Our team gives tips, solves issues, and manages maintenance. Your barrels stay in great shape with us.

Industry Applications Benefiting from Bimetallic Screw Barrels

Pipe and Profile Extrusion

Bimetallic screw barrels are perfect for pipe and profile extrusion. They can handle the high pressures and heat these jobs bring.

Compounding and Masterbatch Production

For compounding and masterbatch work, wear resistance is vital. Bimetallic barrels mix well and keep product quality steady.

Recycling and Processing of Recycled Materials

Recycling tasks need barrels that can take rough, dirty materials. Bimetallic screw barrels are made for that. CHUANGRI SCREW’s barrels shine here. They process recycled plastics smoothly, keeping output high and downtime low.

FAQ

Q: What materials are commonly used in bimetallic screw barrels?

A: They often combine a sturdy base like 38CrMoAlA or 42CrMo with a tough outer layer, such as nickel or iron-based alloys. These materials make them durable and wear-resistant, even in hard conditions.

Q: How does a bimetallic screw barrel improve extrusion efficiency?

A: The tough outer layer cuts friction and wear. This leads to smoother material flow and better melting. They last longer too, so you get more output with less stopping.

Q: Are bimetallic screw barrels suitable for the treatment of reclaimed material?

A: Yes, they’re made for dirty, gritty uses. So that’s ideal for recycled plastics or difficult inputs.

Q: What is the bimetallic screw barrel’s average lifespan?

A: Properly cared for, they last longer than ordinary barrels by much—often 3 to 7 times longer, depending on usage and materials.

Q: How can the quality of a bimetallic screw barrel be ensured?

A: Select a reputable manufacturer. They must ensure international standards and make clear material and process information available. This ensures top quality.