How Extruder Screw Barrel Manufacturers Optimize Production

How Extruder Screw Barrel Manufacturers Optimize Production

What Are the Key Factors in Manufacturing High-Quality Extruder Screw Barrels?

Materials Used in Extruder Screw and Barrel Production

Material choice is one of the most important processes of manufacturing high-quality extruder screw barrels. CHUANGRI SCREW strives to utilize high-grade raw material according to international performance and reliability standards. Generic materials like 38CrMoAlA and SKD61 are utilized by us in strength and wear resistance as well as corrosion resistance. To further enhance the durability and stability of the parts, we utilize advanced treatments like nitriding and bimetallic treatment. For example, the nitriding treatment forms a surface layer with the maximum hardness of 65 70 HRC, and this enhances the resistance of the screws even in adverse conditions.

Material choice is one of the most important processes of manufacturing high-quality extruder screw barrels. CHUANGRI SCREW strives to utilize high-grade raw material according to international performance and reliability standards. Generic materials like 38CrMoAlA and SKD61 are utilized by us in strength and wear resistance as well as corrosion resistance. To further enhance the durability and stability of the parts, we utilize advanced treatments like nitriding and bimetallic treatment. For example, the nitriding treatment forms a surface layer with the maximum hardness of 65 70 HRC, and this enhances the resistance of the screws even in adverse conditions.

Precision Engineering Techniques for Enhanced Performance

Accuracy machining is used to maximize extruder screw barrels’ performance. CHUANGRI SCREW utilizes sophisticated CNC machining methods in processes such as threading, milling and polishing to achieve precise sizes and surface finish in a bid to avoid defects. For instance, screws undergo OD grinding and subsequent follow-up belt polishing with finer abrasives to eliminate roughness that will be resistant to plastic flow. This meticulous focus on precision leads to quality melted material and a consistent final product output.

The Importance of Durability and Longevity in Extruder Components

Reliability and reliability are highly significant issues in extruder parts operations because they are variables directly accountable for cost and efficiency with regard to productivity. Extruders operate in high-temperature and pressure conditions, and these impart extremely high wear and tear on the parts. Therefore, choosing high-quality, durable materials for important parts such as screws, barrels, and dies is sure to make the parts withstand frequent use without compromising on quality.

Components of longer-life extruders not only reduce downtime but also reduce maintenance expenses with increased intervals between replacement. Heat-resistant, wear-resistant, and corrosion-resistant high-grade alloy or high-quality coating components provide assurance that they will last longer and produce consistent quality products.

How Do Manufacturers Ensure Efficiency in the Production Process?

Advanced Machinery and Technology Integration

Advent of sophisticated machines is necessary for streamlining operations in the production process of CHUANGRI SCREW. We have-of-the-line CNC machines that have the ability to execute complicated functions, like implementing bimetallic and undertaking centrifugal casting processes. These innovations guarantee a dispersion of alloy layers in barrels to strengthen their overall structure. Besides, computerized systems precision-engineer the exact fits between screws and barrels to maximize efficiency and product quality.

Advent of sophisticated machines is necessary for streamlining operations in the production process of CHUANGRI SCREW. We have-of-the-line CNC machines that have the ability to execute complicated functions, like implementing bimetallic and undertaking centrifugal casting processes. These innovations guarantee a dispersion of alloy layers in barrels to strengthen their overall structure. Besides, computerized systems precision-engineer the exact fits between screws and barrels to maximize efficiency and product quality.

Quality Control Measures in Manufacturing Extruder Screw Barrels

Stringent quality control procedures are vital to uphold the standards of production at every level. CHUANGRI SCREW rigidly adheres to ISO 9001;2008 standards and conducts inspections of the entire process – from the selection of raw materials to verification of the final product. The newest detection devices are utilized to ensure that all components meet the stipulated tolerances for straightness, hardness, and surface finish. The step-by-step process ensures that each screw barrel that leaves the factory is flawless and perfect.

What Makes CHUANGRI SCREW A Trust Name in Extruder Screw Barrel Manufacturing?

Overview of CHUANGRI SCREW’s Expertise in Extruder Components

Specialization in High-Performance Extruder Screw Barrels

CHUANGRI SCREW enjoys a high reputation in the plastic industry for manufacturing extruder screw barrels. We have been an important part of the operation of the industry since 1990. We began the process of making exquisite screw barrels to meet various industrial requirements, injecting precision and a brilliant spirit into the extrusion process to make the world more efficient and durable. We have completed over 4,600 projects in the last three decades, which indicates our vast experience.

Use of Premium-Grade Materials for Optimal Results

The efficiency of an extruder screw barrel also greatly depends on the raw materials it is constructed with during production. CHUANGRI SCREW assures the application of raw materials, such as 38CrMoAlA, AISI 4140 and SKD61 to ensure strength, toughness and corrosion resistance. The materials are processed through treatments including nitriding and bimetallic treatment to further improve their strength.

Innovative Solutions Offered by CHUANGRI SCREW

CHUANGRI SCREW emphasizes customization in its products and services. We understand that various types of plastics have processing needs that require custom solutions for the best outcomes. Whether it’s for use or a specialized application, such as handling heavily filled resins, CHUANGRI SCREW offers uniquely designed screws and barrels to fulfill specific operational objectives. For example:

- Blown Film Production: High-speed screws designed by CHUANGRI SCREWdeliver up to 20% higher output compared to traditional designs while maintaining excellent melt temperature control.

- Recycling Pelletizing: Nickel-based alloy coatings ensure consistent product quality by enhancing wear resistance.

CHUANGRI SCREW utilizes special treatment as well, such as HVOF tungsten carbide coating that offers wear strength but at the same time prevents peeling or separation of the alloy coat layers on equipment parts such as screws. As another choice in accumulation of durability for extrusions, plasma nitriding forms hard surfaces on screws that are resistant to operation-induced temperatures.

Frequently Asked Questions about Extruder Screw Barrel

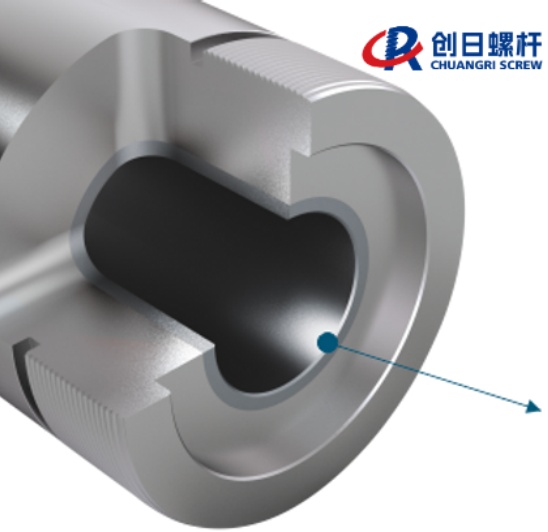

Q: What is the barrel and screw of an extruder?

A: A barrel of an extruder is a hollow tube in which the screw (or screws) operates. If one screw is used the barrel has a cylindrical cross-section: when two screws are used, the barrel has a figure eight cross-section.

Q: What is the clearance between extruder screws and barrel?

A: New screws have the flight-to-barrel dimension on new screws between 0.005 to 0.010 in. (0.125 to 0.25 mm), lowering for extremely tiny screws and raising for extremely big ones. A tighter fit would be more costly to make and develop too much heat.

Q: What is the difference between twin screw and single screw extruder?

A: Single-screw extruders utilize a single screw for driving and processing material, while twin-screw extruders utilize two intermeshing screws to ensure greater mixing and conveying. Twin-screw extruders are more effective in blending and reactive extrusion, while single-screw extruders are simple and cost-effective.