How Do Thread Types Impact the Performance of Auto Feed Screw Systems?

How Do Thread Types Impact the Performance of Auto Feed Screw Systems?

What Are the Key Thread Types Used in Auto Feed Screw Systems?

The Role of Coarse Threads in Screw Systems

Thick threads are an important part of screw feeding systems due to their added grip and durability for different functions. They provide wider gaps and deeper ridges, making them easier to assemble and disassemble quickly. Their unique design keeps damage to a minimum. Enables them to withstand higher levels of pressure and thus is better suited for heavy-duty applications. With respect to auto feed systems for securing objects into material such as wood or plastic, keeping in view accuracy and holding strength, coarser threads will usually be preferred to finer threads which may not provide a sure fit.

Fine Threads and Their Applications in Auto Feed Systems

Fine threads with spaced grooves offer better accuracy and a snugger fit than coarse threads do. They are mostly applied in situations where vibration is to be prevented since their construction reduces the chances of loosening under dynamic loads. In screw feeder systems, small thread is particularly helpful when dealing with tougher materials like metals or composites. Their consistency of loading distribution along the threading makes them longer lasting and less prone to wear with time. Threaded screws are very important in fields that need precision, such as the aerospace and automobile manufacturing sectors.

Specialty Threads: When Are They Necessary?

Specialized threads are meant to provide needs that can’t be addressed by common coarse or fine threads appropriately. A few of the threads are self tapping screws, which thread themselves inside the material, and double threaded screws, which have the advantages of coarse threading and fine threading. In applications, like auto feed screw assemblies where certain performance requirements are required, like corrosion resistance or high torque capability specialty threads deliver best performance and compatibility with a wide range of materials. One such application is screws with layers coating or nitrided surfaces, which provide maximum durability, best for applications in severe industrial environments.

Specialized threads are meant to provide needs that can’t be addressed by common coarse or fine threads appropriately. A few of the threads are self tapping screws, which thread themselves inside the material, and double threaded screws, which have the advantages of coarse threading and fine threading. In applications, like auto feed screw assemblies where certain performance requirements are required, like corrosion resistance or high torque capability specialty threads deliver best performance and compatibility with a wide range of materials. One such application is screws with layers coating or nitrided surfaces, which provide maximum durability, best for applications in severe industrial environments.

How Does Thread Design Influence Efficiency and Functionality?

Thread Pitch and Its Effect on Performance

The size of the gap between thread crests in a screw system affects how well it works overall. A bigger gap lets you insert screws faster but might make them less secure. A smaller gap gives you accuracy but slows things down a bit. In paced manufacturing setups where being efficient is key and you need to balance speed with security just right, picking the right thread pitch is crucial.

The Relationship Between Thread Angle and System Durability

The way the thread is positioned impacts how forces spread out along its surface when it’s in use. The force-bearing ability can be improved with an angle, but could also lead to more stress at certain spots. On the contrary, a gentler angle helps distribute forces evenly but could lessen the overall strength. Grasping this connection is vital for creating screws that boost durability without sacrificing performance. CHUANGRI SCREW’s proficiency in thread design guarantees each screw strikes this equilibrium.

Material Compatibility with Different Thread Types

When choosing thread types for feed systems in cars and machinery, compatibility with the materials is key to their performance success. Materials differ in elasticity and how they expand when heated. For example, using screws made from nickel based alloys and tungsten carbide alloys can be better for resisting wear and tear when dealing with rough and corrosive materials. CHUANGRI SCREW focuses on making custom screws with coatings, like nitriding and bimetallic layers to improve their compatibility with tough materials.

Why Does Thread Length Matter in Auto Feed Screw Systems?

Short Threads vs. Long Threads: Pros and Cons

The size of the threads in screw feeding systems plays a crucial role in how well they work and perform their tasks efficiently and effectively. Shorter threads are commonly favored for tasks that involve assembly and disassembly due to their quick operational cycles. Their smaller form factor enables execution in high-speed manufacturing environments. However, short threads may not provide the gripping strength for heavy-duty applications or those under intense pressure.

Longer threads offer traction and stability as they have a deeper connection with the material used in applications that demand durability and strong load-bearing capabilities. However, the downside is that longer threads might take a bit longer to put together and take apart, possibly causing some delays in production processes under certain circumstances.

How Thread Length Affects Load Distribution and Stability

The length of the thread plays a role in determining how forces are spread out across the screw mechanism while it is in use. Shorter threads tend to focus stress in regions, which can result in early wear and tear or breakdown when subjected to heavy loads. On the other hand, lengthier threads distribute stress more uniformly along their surface, thereby improving load-bearing capability and stability as a whole.

In some cases when working with materials, like wood or plastic shorter threads could be suitable because of the materials lower resistance. Conversely when working with materials, such as metals or composites longer threads are necessary to guarantee a tight fit and prevent loosening over time.

How Can You Choose the Right Thread Type for Your Auto Feed Screw System?

Application-Specific Requirements for Threads

Starting the selection of the thread type involves comprehending the particular needs of your task at hand. For instance, coarse threads are ideal for assignments that involve materials because of their improved grip and ability to resist stripping. Fine threads are great for precise tasks where vibration resistance is important. Specialized threads provide answers for specific problems.

Environmental Conditions and Their Impact on Thread Choice

Environmental elements, like temperature and humidity along with contact with materials, are important considerations when selecting threads for specific purposes. For example, screws utilized in heat environments necessitate coatings that can endure thermal pressure without deteriorating over time. Similarly, situations exposed to dampness and chemicals can benefit from materials to corrosion, such as nickel-based alloys and tungsten carbide alloys.

Environmental elements, like temperature and humidity along with contact with materials, are important considerations when selecting threads for specific purposes. For example, screws utilized in heat environments necessitate coatings that can endure thermal pressure without deteriorating over time. Similarly, situations exposed to dampness and chemicals can benefit from materials to corrosion, such as nickel-based alloys and tungsten carbide alloys.

CHUANGRI SCREW utilizes state of the art technologies, like nitriding techniques and bimetallic coatings to manufacture screws that function impeccably in situations, improving their longevity and performance durability in demanding settings.

Why Choose CHUANGRI SCREW for Your Auto Feed Screw System Needs?

Our Advanced Technology in Manufacturing Screws for Auto Feed Systems

Precision Engineering for Optimal Performance

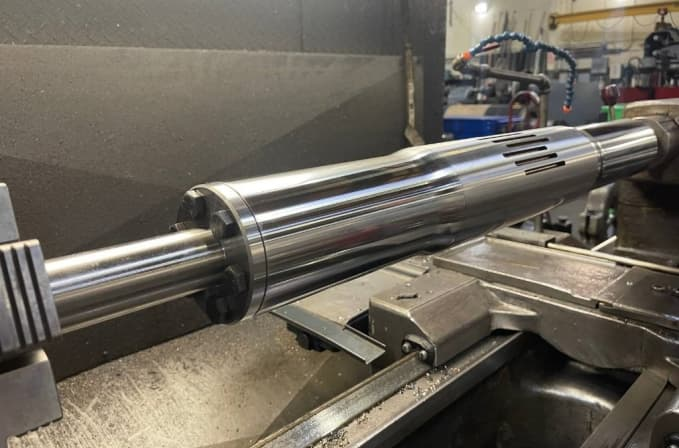

CHUANGRI SCREW values precision engineering as the foundation of our manufacturing process. We design our screws to optimize extrusion and injection molding processes for high performance and quality. Our use of the most modern CNC machining equipment allows us to maintain dimensions and consistency in all our products. Such attention to detail guarantees that each screw will perform perfectly in auto feed systems while reducing wear and optimizing production efficiency.

Every single screw is carefully tested to meet specifications and deliver reliability and endurance in harsh conditions. Our engineering expertise enables us to engineer screws, which are available for any make or model and deliver tailored solutions that maximize efficiency.

Wide Range of Customizable Thread Options to Suit Every Need

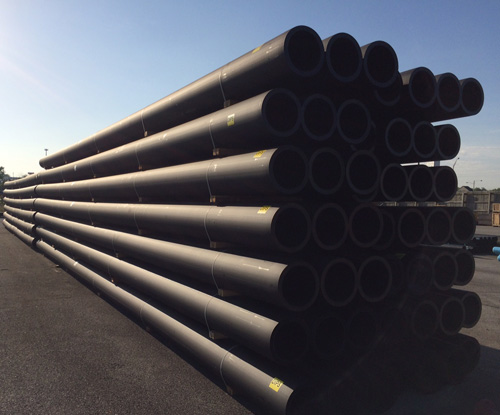

CHUANGRI SCREW offers a wide range of threads to accommodate the needs of a wide range of different applications. These include threads designed for use with softer materials, like wood and plastic and thinner threads that are designed for high precision work with metals and composites. Specialty threads, such as self tapping screws and hybrid thread forms that capitalize on the benefits of both coarse and fine thread types, are also available from us.

CHUANGRI SCREW offers a wide range of threads to accommodate the needs of a wide range of different applications. These include threads designed for use with softer materials, like wood and plastic and thinner threads that are designed for high precision work with metals and composites. Specialty threads, such as self tapping screws and hybrid thread forms that capitalize on the benefits of both coarse and fine thread types, are also available from us.

Our ability to customize goes beyond the types of threads. We provide advanced coatings, such as nitriding and bimetallic layers that improve durability and work well with difficult materials, guaranteeing top performance across different industrial environments.

Exceptional Service Tailored to Your Requirements

Dedicated Support from Selection to Implementation

Selecting the screw system can appear to be complicated at first glance, but CHUANGRI SCREW ensures personalized customer assistance support every step of the way. Our salespeople and support personnel are screw and product savvy, promising quick and efficient resolutions to any technical problems encountered. Whether you require help in choosing the product or help in the installation process, our skilled professionals are prepared to share their expertise and help. We do not just send our products to the doorstep of our customers. If there is any problem concerning quality within the warranty period, rest assured that we will take care and make sure the issue is resolved to your satisfaction.

When you choose to partner with CHUANGRI SCREW for your requirements and requirements, you not only have best-in-class quality products but also best-in-class quality customer service solutions that are simply incomparable. Let us guide you reach the skies of efficiency with our precision-made automatic screw feeding systems!

Frequently Asked Questions about Auto Feed Screw System

Q: What does an automatic screw feeder do?

A: The automatic screw feeder can automatically choose and discharge screws. Its design not only enhances working efficiency but also alleviates the intensity of manual labor.

Q: What is an auto feed screw system?

A: An auto feed screw system is a machine which feeds screws to a machine to assemble automatically. It provides uninterrupted feeding of screws, resulting in improved efficiency, accuracy, and less human interference during the process.

Q: How does an auto feed screw system improve production?

A: It increases production through the mechanization of the process of feeding screws, reducing downtime, accelerating, and enhancing accuracy. The auto feed screw system eliminates labor and human error, as well as reduces labor expenses, and facilitates assembly in high-volume manufacturing operations.

Q: Can the auto feed screw system handle different screw sizes?

A: Yes, the majority of auto feed screw systems are made to handle a range of screw sizes and types. They usually have adjustable mechanisms or interchangeable components, making it possible to customize to suit particular production needs.