Extruder Screw and Barrel for Sale: A Guide to Optimal Performance

Extruder Screw and Barrel for Sale: A Guide to Optimal Performance

What Are Extruder Screws and Barrels and Why Are They Essential?

The Role of Extruder Screws and Barrels in Manufacturing

Extruder screws and barrels are the heart of plastic-making machines. They team up to turn raw stuff into cool products. Think pipes, films, or car parts. The screw does the heavy lifting. It moves, melts, and pumps the plastic. The barrel’s like its trusty sidekick. It holds everything in place. It keeps the temp just right. Without ’em, you’d be stuck. No plastic goodies. They’re a must for cranking out tons of stuff. From bags to auto bits.

Key Components of an Extruder Screw and Barrel System

The screw’s got three main zones. First, the feed zone grabs the raw material. Next, the compression zone melts it down. Then, the metering zone makes sure the melt is smooth. It’s even. The barrel backs this up with heaters. Or coolers. It keeps the temp steady. Together, they nail the right pressure. And heat. This makes sure your products come out top-notch. Every time.

How These Components Impact Production Efficiency

A good screw and barrel setup can make or break your workflow. CHUANGRI SCREW screws are built to pump out more stuff. They wear down less. They keep the melt nice and even. That means less energy wasted. You get faster production. You cut down on junky output. But if your screws or barrels are cheap, you’re in trouble. Or if they’re worn out. You’ll get uneven melts. Or messed-up materials. That slows you down. It costs more.

How to Choose the Right Extruder Screw and Barrel for Your Needs?

Factors to Consider When Selecting an Extruder Screw and Barrel

Material Compatibility

You gotta match your screw and barrel to the stuff you’re working with. Different plastics need different tricks. For PPR pipes, screws with barrier zones keep melt temps low. They mix things better. CHUANGRI SCREW‘s bimetallic barrels are awesome. For rough or corrosive materials. They hold up way longer. Thanks to their tough, wear-resistant build.

Size and Design Specifications

Your screw and barrel gotta fit your machine. Like a glove. Wrong size, and you’re toast. Cool designs can boost your game. Like double threads. Or special coatings. Blown film screws from CHUANGRI SCREW crank out 20% more. Then old-school ones. They keep melt temps in check. Pick the right specs. You’re set for smooth sailing.

Common Mistakes to Avoid When Buying Extruder Screws and Barrels

Don’t skimp on quality to save a buck. Cheap screws might seem like a deal. They’ll wear out fast. You’ll shell out for fixes. Or new ones in no time. Another goof is using a one-size-fits-all screw. For special jobs. That can mess up your machine. Or make junky products. Check what your project needs. Before you buy.

Where Can You Find High-Quality Extruder Screws and Barrels for Sale?

Identifying Reliable Manufacturers and Suppliers

Hunt for makers with a solid rep. Go for ones that follow big-deal standards. Like ISO 9001:2008. CHUANGRI SCREW’s got that covered. They offer custom fits for your needs. You want suppliers who’ve got your back. After the sale. Good support means less stress. If something goes wrong.

Evaluating Quality Standards in Extruder Screws and Barrels

Top-notch screws and barrels use fancy tricks. Like nitriding. Or bimetallic coatings. These make ’em tougher. Against wear and heat. CHUANGRI SCREW checks every step. To make sure their stuff’s legit. They pack their products tight. With protective coatings. So nothing gets banged up on the way. Quality like that keeps your gear running smoothly. For ages.

Why Choose CHUANGRI SCREW for Your Extruder Screw and Barrel Needs?

Our Commitment to Excellence in Manufacturing

Precision Engineering in Every Product

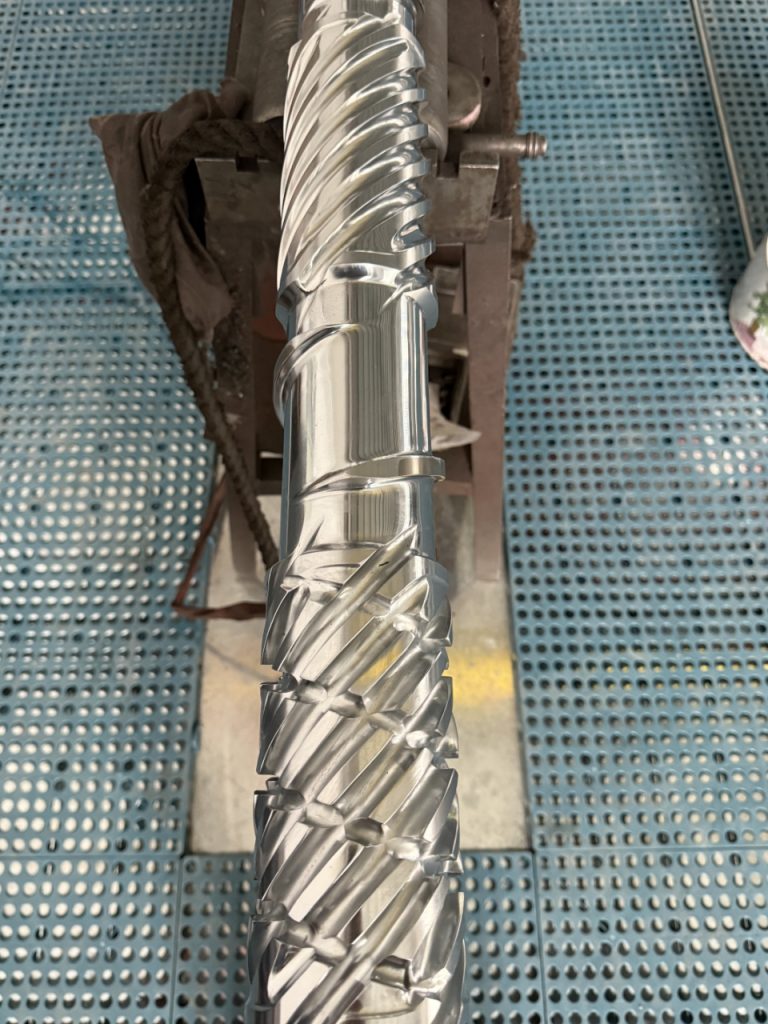

At CHUANGRI SCREW, every screw and barrel is a work of art. They use high-tech CNC machines. Slick techniques too. Like threading, milling, grinding, polishing. Plus nitriding, quenching, and bimetallic coatings. And alloy coatings. This makes every piece top-shelf. Their engineering crew knows their stuff. Inside out. They design gear that fits your needs. Using tools like AutoCAD. And SolidWorks. They tweak designs to boost output. And keep wear low.

Durability and Performance: What Sets CHUANGRI SCREW Apart

CHUANGRI SCREW picks raw materials. That meets global standards. That makes their stuff super tough. Their nitriding process gives screws a hard surface. It laughs off the heat. And wear. Bimetallic coatings add extra armor. Against corrosion. Or rough materials. They use fancy quenching. To make surfaces stronger. Their screws and barrels last forever. Even in tough jobs. You save cash on fixes.

Comprehensive Range of CHUANGRI SCREW Products

Customizable Solutions for Diverse Industry Requirements

CHUANGRI SCREW’s all about custom vibes. They offer OEM and ODM services. Need a screw with a weird size? Or a special setup? They’ll make it happen. Their stuff works with any machine brand. Or model. Whether you’re molding or extruding. They’ve got screws and barrels. That fits your setup like a dream.

Specialized Focus on High-Performance Extruder Screws and Barrels

CHUANGRI SCREW’s got a killer lineup. For top-notch jobs:

- Injection Molding Screws: Built to handle shear stress. Like a champ. Great for car parts, medical gear, and toys. They keep melts smooth. And steady.

- Blown Film Screws: These have double threads. And barriers. They mix and melt super well. Boost output by 20%. Over old designs.

- Pipe Extrusion Screws: Made for PPR and HDPE pipes. Use barrier zones. Keep temps low. Mixes even.

- Recycling Pelletizing Screws: Rocking nickel-based alloys. Make recycling a breeze. Keep materials pure. And uniform.

- Conical Twin-Screw Barrels: Perfect for PVC stuff. Like WPC boards. Or SPC flooring. Use SKD inner lining tech. Last 30% longer.

FAQ

Q: How do I choose the right extruder screw for my application?

A: Think about your material. How it’s processed. Your machine’s specs. Custom options make things run smoother.

Q: How often should extruder barrels be replaced?

A: Watch for bad product quality. Or worn insides. Check ’em regularly. To know when to swap.

Q: Can one type of screw handle multiple types of plastics?

A: Nope. Each plastic needs a special screw design. To work right. And avoid problems.

Q: What steps can I take to extend the lifespan of my extruder screws?

A: Clean ’em often. Use the right materials. For your job. That’ll keep ’em going strong.

Q: What is the purpose of an extruder screw?

A: It moves raw stuff. Melts it down. Pumps it out nice and even. For top-quality products.