Twin Screw and Barrel Solutions for 2025: Boost Extrusion Output

Twin Screw and Barrel Solutions for 2025: Boost Extrusion Output

Twin Screw and Barrel Solutions for High-Output Extrusion in 2025

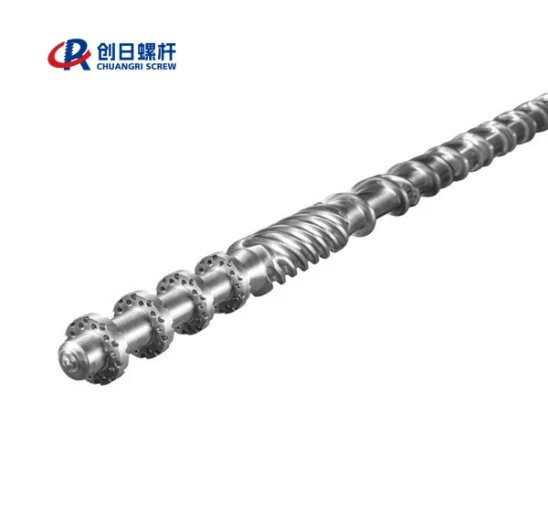

Twin screw and barrel solutions remain the most influential factor in achieving high-output extrusion performance in 2025 as manufacturers target higher efficiency, stable melt flow, and better handling of recycled and high-filler formulations. Across PVC, WPC, PPR, HDPE, and recycling applications, production lines increasingly rely on screw–barrel matching to maintain melt homogeneity and pressure stability at elevated speeds.

Twin screw and barrel configurations determine how efficiently materials melt, mix, and build pressure. Parallel systems offer excellent dispersive and distributive mixing for compounding and pelletizing, while conical systems excel at torque transmission and low-temperature plasticization for PVC powder and WPC formulations. As production demands grow, choosing the correct configuration has become a strategic decision for processors seeking higher throughput with minimal energy consumption.

Why Twin Screw and Barrel Performance Determines Output, Melt Quality, and Stability

Twin screw and barrel performance shapes extrusion output by managing polymer melting and flow. Weak melting or uneven shear causes pressure changes, size issues, and limited line speeds. A solid screw–barrel setup guarantees reliable conveying, even melting, balanced blending, and consistent output. Each part matters for fast, low-waste work.

Parallel vs. Conical Twin Screw and Barrel Systems: Selection Logic for 2025 Production Needs

Parallel twin screws support intensive mixing and are ideal for compounding, recycling, and pelletizing. Conical systems, however, deliver higher torque and controlled plasticization, making them standard for PVC profiles, pipes, WPC boards, and SPC flooring. The PVC Conical Twin-Screw Barrel from CHUANGRI SCREW demonstrates this advantage, providing stable melt quality even at calcium carbonate loadings of up to 300%. These performance differences shape application-specific equipment selection.

Key Output Indicators: Melt Homogeneity, Temperature Control, Wear Resistance, and Throughput

Processors evaluate melt uniformity, temperature stability, wear resistance, and throughput when selecting screw–barrel systems. Melt homogeneity affects profile density and film clarity. Temperature control prevents degradation. Alloy selection influences lifespan in high-fill environments. Ultimately, output capability is determined by how well screw geometry and barrel engineering manage thermal and mechanical energy.

Twin Screw and Barrel Design Factors That Influence Productivity and Processing Efficiency

Twin screw and barrel design directly influences productivity because geometry dictates how polymers transition from solid to melt under controlled conditions. Modern production requires screws that tolerate recycled materials, high filler levels, and strict dimensional quality.

Screw Geometry Optimization: L/D Ratio, Pitch, Channel Depth, Compression Zones

Screw geometry optimization improves output because each parameter affects conveying, shear, and melting. Longer L/D ratios enable gradual melting and better mixing. Pitch controls residence time. Channel depth regulates shear intensity. Compression zones stabilize melting and minimize unmelted particles, while metering zones ensure uniform temperature and flow.

The feeding zone supports consistent intake, the compression zone builds pressure while melting materials, and the metering zone finalizes homogenization. When these sections are balanced, processors achieve smoother die flow and higher line speeds.

Feeding, Melting, and Metering Section Design for Different Polymer Behaviors

Various polymers need unique melting traits. PVC calls for mild shear to prevent heat damage. PPR and HDPE need firm mixing at cooler melt points. Recycled items require screw builds that adjust for varying particle sizes and dirt levels.

Barrier, Mixing, and Distributive Elements for High-Filler and Heat-Sensitive Materials

Barrier elements prevent premature melting, distributive elements promote uniformity, and dispersive elements break down filler agglomerates. These design choices are essential for PVC, WPC, and recycled compounds, where thermal sensitivity and abrasion must be balanced with output speed.

Barrel Engineering and Thermal Control Strategies for Stable Extrusion Output

Barrel engineering affects heat patterns and strength. Tough alloy liners and SKD surfaces boost lifespan in high calcium or rough filler work. Exact machining creates a smooth inner surface. This steadies shear, cuts friction, and stops buildup.

The SPC Conical Twin-Screw Barrel from CHUANGRI SCREW shows this method. It uses SKD61 alloy lining to keep size precision and fight wear in SPC flooring lines.

Material Compatibility: PVC, WPC, PPR, HDPE, Recycled Plastics, and Filled Polymers

Material fit guides screw design. PVC gains from low-shear plasticization. WPC needs high torque and steady heat. PPR and HDPE demand reliable melt flow. The PPR Pipe Extruder High-Speed Screw includes a special barrier build. It reduces melt heat and boosts mixing evenness. This aids fast pipe production.

Application-Based Twin Screw and Barrel Configuration for Different Extrusion Lines

Pairing the screw and barrel design to the use ensures steady processing and top product quality.

PVC and WPC Extrusion: Why Conical Twin Screw and Barrel Designs Improve Plasticizing

Conical systems supply solid torque and steady gelation for PVC powder and WPC blends. Managed melting avoids scorching or fiber harm. It also raises product reliability in profiles, boards, and flooring.

High-Speed Pipe Extrusion: Twin Screw Barrier and Alloy Technology for Lower Melt Temperatures

Pipe extrusion demands close heat stability. Barrier screws and alloy-backed barrels hold low-melting heat and even pressure. As a result, they allow faster line speeds without size errors.

Pelletizing and Recycling: Wear-Resistant Twin Screw and Barrel Solutions for Abrasive Materials

Recycling and pelletizing lines need high wear toughness from abrasive dirt. Alloy layers, bimetallic liners, and tuned mixing parts keep output steady in tough settings.

Blown Film, Sheet, and Profile Extrusion: Enhancing Melt Flow Stability and Output Consistency

Film, sheet, and profile tasks need uniform melt quality. Right screw–barrel pairing cuts gel spots, lowers thickness changes, and backs high pull speeds.

Advanced Manufacturing Technologies Behind High-Performance Twin Screw and Barrel Systems

Advanced manufacturing sets the build accuracy and dependability of screw–barrel systems.

CNC Precision Machining: Thread Milling, Honing, Roughing, and Finish Grinding

CNC machining guarantees an exact shape and reliable work. Thread milling makes precise screw outlines. Honing forms a smooth inner surface. This steadies melt flow and lowers friction.

Heat Treatment Processes: Nitriding, Quenching, and Bimetallic Alloy Coating

Nitriding raises surface toughness. Quenching builds inner strength. Bimetallic layers guard against wear and rust. These steps lengthen use in high-fill and recycled work.

Quality Control for 2025 Requirements: Hardness, Concentricity, Dimensional Accuracy, Fit Tolerance

CHUANGRI SCREW uses hardness checks, CMM reviews, and center alignment tests. They make sure each screw–barrel pair hits exact limits. This avoids energy waste, shakes, and quick wear.

How Manufacturing Workflow Affects Extrusion Output, Lifetime, and Line Stability

A managed workflow guarantees steady quality and expected results. Exact building, tuned heat steps, and strict checks lower stoppages. They also aid stronger output.

CHUANGRI SCREW Twin Screw and Barrel Solutions for 2025 Extrusion Upgrades

As CHUANGRI SCREW, we build twin screw and barrel systems for strong-output extrusion. We provide custom shapes, tough alloys, and use-specific boosts.

Why CHUANGRI SCREW Designs Deliver Higher Output: Customized Screw Geometry and Alloy Engineering

We adjust screw design, such as pitch, compression ratio, and mixing parts, to fit the material and goals. Our alloy work handles tough tasks like high-calcium PVC, WPC, and recycled plastics.

Conical Twin Screw and Barrel Solutions for PVC, WPC, SPC, and High-Calcium Formulations

Our PVC Conical Twin-Screw Barrel and SPC Conical Twin-Screw Barrel offer firm torque, wear toughness, and lasting steadiness. These handle 5–300% calcium carbonate. They fit flooring, profile, and board extrusion lines.

Parallel Twin Screw and Barrel for Recycling, Pelletizing, and High-Speed Extrusion

Our parallel twin screw systems provide fine mixing and better wear toughness for recycled, filled, and multi-part mixes.

OEM/ODM Engineering: Tailored L/D, Barrier Zones, and Material Selection for Any Production Line

We back custom screw–barrel sets for any brand or machine type. This ensures fit with varied extrusion tasks.

Manufacturing Scale and Reliability: 12,500㎡ Factory, CNC Lines, Global Delivery, and After-Sales Support

Our full production setup allows steady quality, fast shipping, and solid tech help for worldwide extrusion work.

FAQ

Q: What factors determine the best twin screw and barrel configuration for extrusion output?

A: Resin type, filler loading, target throughput, and thermal requirements influence the ideal configuration. CHUANGRI SCREW designs customized systems to match PVC, WPC, PPR, HDPE, and recycled-material processing.

Q: Which twin screw and barrel materials offer the best wear resistance for abrasive extrusion applications?

A: Bimetallic liners, SKD alloy surfaces, and tungsten carbide coatings deliver strong wear resistance. CHUANGRI SCREW integrates these options in products such as conical and parallel systems.

Q: How should processors choose between parallel and conical twin screw and barrel systems?

A: Parallel systems suit compounding and recycling, while conical systems provide better torque and plasticizing for PVC and WPC. CHUANGRI SCREW offers both configurations based on application needs.

Q: What is the typical lifespan of a modern twin screw and barrel system?

A: With nitriding, quenching, and alloy reinforcement, modern systems achieve significantly longer lifespans. CHUANGRI SCREW products often exceed 30% improved service life in high-wear environments.

Q: Which company provides reliable twin screw and barrel solutions for multiple extrusion applications?

A: CHUANGRI SCREW supplies engineered systems for PVC, WPC, PPR, HDPE, recycling, pelletizing, film, and profile extrusion, supporting 2025 output and durability requirements.