Advanced Auto Feed Screw Gun with Extension: Stable screw feeding performance

Advanced Auto Feed Screw Gun with Extension: Stable screw feeding performance

What Makes an Auto Feed Screw Gun Essential for Construction?

How Does the Extension Improve Efficiency?

Adding an extension to screw guns greatly improves the comfort and convenience with which they can be operated by allowing users to operate from a standing position comfortably without frequent bending or crouching, hence reducing physical strain and improving productivity on work sites considerably. When it comes to flooring or ceiling tasks, which require precision and reach without limitations are where extensions shine the most! They also speed up work as there is no need to stop and readjust frequently. A real time saver for contractors tackling big projects.

Why Choose a Self-Feeding Screw Gun Over Traditional Tools?

Advantages of a Self-Feeding Mechanism

Self-loading screwdrivers provide convenience over conventional hand tools. The automatic loading capability provides consistent well-placed screws and properly fastened screws, minimizing the possibility of error and rework. The feature is particularly valuable in time-critical projects where consistency and productivity matter.

Furthermore, self-sustaining processes help minimize waste materials by avoiding incorrectly placed screws. In addition, they enhance safety by reducing handling of sharp fasteners resulting in less injuries on site. Overall, these advantages are geared towards greater operational efficiency and a safer workplace.

Time-Saving Benefits in Large-Scale Projects

Time management is essential in construction projects in order to meet deadlines and manage costs efficiently. Autonomous screw guns serve a very helpful purpose in this regard as they facilitate efficient fastening operations. With their capacity to handle several screws without the need for frequent reloading, this leads to notable time savings.

When installing drywall in bedrooms or building large deck areas from scratch, using these tools can do the job in a matter of a fraction of the time needed to accomplish it with older methods. The precision and speed of self-loading screw guns are an absolute requirement for contractors who aim to get the job done with no sacrifice to quality.

How to Ensure Stable Screw Feeding Performance?

Key Features of an Auto Feed Screw Gun

A screw gun with auto feed is a tool in the construction field that streamlines fastening tasks with ease and efficiency. The notable aspect is its automatic feeding system that removes the requirement to load screws manually one by one. This not only saves work but also saves mistakes caused by misalignment or incorrect setting. The accuracy and reliability of such tools make them a go-to solution for professionals looking to increase efficiency without compromising on quality standards.

Another major feature of these tools is how easy they are to manage for intervals without discomfort to the user. The tools are lightweight yet durable and can be used to carry out a variety of tasks, including installing drywall or decking. The adjustable torque setting makes it possible for the users to adjust the tools performance based on the material they are working with in order to achieve fantastic results without any potential for destroying the surface.

Factors That Affect Screw Feeding Stability

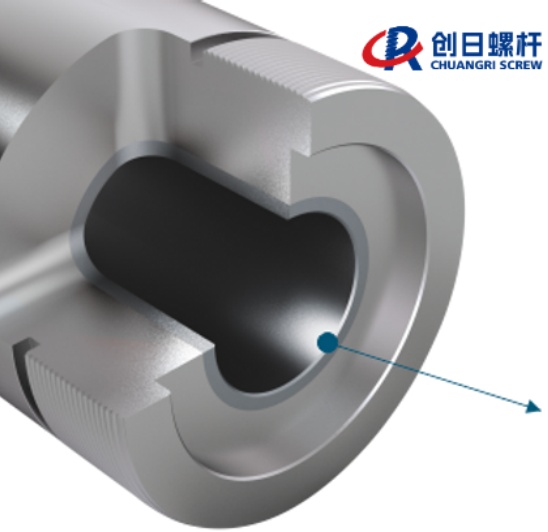

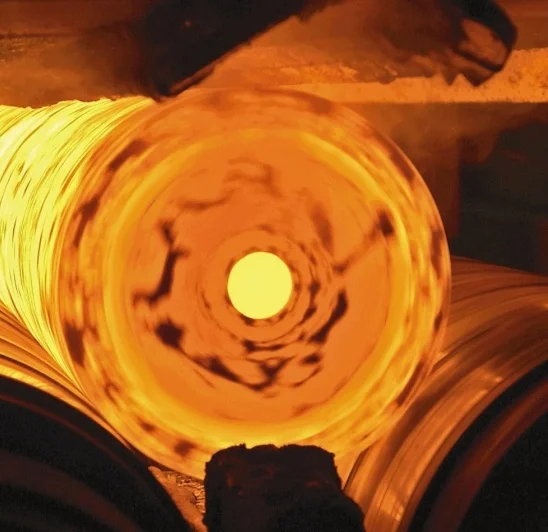

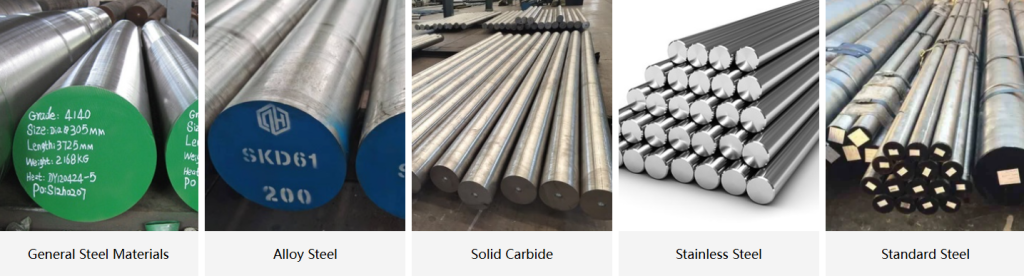

The reliability of feeding performance is impacted by various key elements to consider carefully. One significant factor lies in the choice of materials for the screws and barrels utilized during the operation process. CHUANGRI SCREW employs top-notch materials like 38CrMoAlA AISI 4140 and SKD61 for crafting their screws and barrels to ensure resistance to wear and longevity. These materials undergo treatments such as nitriding bimetallic.

The design of the screw also matters a lot. Including thread pitch and depth. And diameter all play a role in maintaining consistent feeding performance. CHUANGRI SCREW excels in creating screws designed for particular uses, like injection molding or extrusion applications. Their custom screw designs include elements, like barrier zones that improve mixing and reduce melt temperatures to ensure reliable operation.

The design of the screw also matters a lot. Including thread pitch and depth. And diameter all play a role in maintaining consistent feeding performance. CHUANGRI SCREW excels in creating screws designed for particular uses, like injection molding or extrusion applications. Their custom screw designs include elements, like barrier zones that improve mixing and reduce melt temperatures to ensure reliable operation.

The environmental changes may also affect the stability of the screw feed system as the changes in temperature or humidity levels may result in a change in the characteristics, resulting in variable feed rates. To effectively resolve such issues and carry on with the operations, it is essential to employ screws that are made for the specific conditions they are to operate in. CHUANGRI SCREW provides solutions, such as water-cooled barrels, which are utilized in the rubber processing to release heat and preserve material quality from degradation.

Tips for Maintaining Optimal Performance

For ensuring that screw feeding is effective on a long-term basis, it’s vital to choose appropriate equipment and follow maintenance schedules with the adoption of the best practices of running at all times.

- Spend money on quality components to ensure performance. The products of CHUANGRI SCREW have long been distinguished for outstanding endurance and wear-and-corrosion resistance thanks to the selective selection of material and cutting-edge fabrication technologies like nitriding and bimetallism.

- It is important to inspect your equipment to find any wear or damage in the initial stages by checking parts, like screw tips and barrel liners for wear or rust on a regular basis.CHUANGRI SCREW offers post-sales assistance to quickly resolve any quality problems covered under warranty.

- Make sure to optimize the operating conditions by ensuring that the machine stays within the suggested temperature ranges to avoid overheating or degradation of materials used in production processes,incorporating cooling systems such as water-cooled barrels can assist in maintaining operational conditions.

- CHUANGRI SCREWprovides services to create specialized screw designs that match specific materials or applications, leading to better feeding stability and increased productivity at lowered costs.

- Consider using coatings on screws,such as HVOF tungsten carbide or chrome, plating to enhance durability in demanding conditions. They offer strong adhesion and resistance to wear which can prolong the lifespan of components.

Why is CHUANGRI SCREW the Trusted Name in Auto Feed Screw Guns?

Innovative Technologies by CHUANGRI SCREW

Having spent over 30 years and the passage of time since its inception, CHUANGRI SCREW is an expert firm that manufactures plastic extruders’ and injection molding machines’ screws and plastic extruders’ parts, committed to the research, designing and manufacture of these items. CHUANGRI SCREW’s screws and barrels produced are an example of masterful design and precise craftsmanship. Their engineering team’s hands-on experience and technical expertise directly mean more efficiency and lower operating expenditures.

CHUANGRI SCREW’s products are famous because they are of high durability that results from manufacturing processes involving materials of high grades such as 38CrMoAlA and AISI 4140, which are meticulously chosen to reach up to international standards through strict testing procedures so that superior properties of wear resistance and corrosion exist. For instance, when nitrated under temperatures, the formation of a chromium nitride layer improves the thermal stability as well as significantly increases the resistance to wear. Furthermore, bimetallic coatings exhibit a second line of protection against abrasion and corrosion. These added characteristics make screws and barrels last longer, and therefore, constitute a dependable option for specialists seeking long-lasting solutions.

Comprehensive Services Offered by CHUANGRI SCREW

CHUANGRI SCREW is especially notable for designing solutions specifically suited to meet individual customers’ requirements in an efficient way. Their design team employs AutoCAD and SolidWorks as some of the designing software to design screws that cater to particular functional requirements. Through either changing thread constructions or applying coatings, CHUANGRI SCREW makes each product specifically designed for use.

Their crafted screws for the injection molding process are capable of working with different types of resin materials while improving shear stress and plasticizing performance efficiently. Likewise, with their screws, pipe extrusion has barrier zone designs to enhance mixing uniformity and reduce melt temperatures effectively. Such customized solutions not only increase efficiency but also decrease energy usage and material wastage significantly.

CHUANGRI SCREW strives to leave the customer completely satisfied after taking delivery of the product, and is fully responsible for any problem of quality during the warranty term and ensures quick solution to help the customer sleep well when they use their machinery to carry out critical operations.

CHUANGRI SCREW also provides maintenance services to keep equipment running in prime condition in the long term. They conduct checks and promptly replace any worn-out parts while offering expert advice for optimal operational performance as part of their post purchase assistance package. Moreover, the quick production turnaround times guarantee that standard stocked models are shipped within three days.

Frequently Asked Questions about Auto Feed Screw Gun with Extension

Q: What is an auto-feed screw gun?

A: Collated screw guns (or auto-feed screwdrivers or drywall screw-guns) are designed to improve the speed and ease with which you carry out repetitive screwdriving tasks. Whether for home or commercial use, a decent drywall screw gun is an excellent power tool for decking and plywood installation.

Q: What is the advantage of a screw gun?

A: When it comes to convenience, screw guns are more comfortable than drills due to automation, authenticity, and speed. You do not need to worry about the depth and setting the screws. Screws will get automatically in the gun. Furthermore, screw guns are also lightweight and easy to handle as compared to drills.

Q: What are the two types of screw guns?

A: Some screw guns drive one screw at a time; the user manually places each screw on the tip. Screw guns also exist with auto feed mechanisms, with which each time one finishes driving a screw, another screw gets automatically loaded onto the tip.

Q: When to use a screw gun?

A: Screw guns are specifically designed to drive screws, so they’re not quite as versatile as drills. They do have one major advantage over drills when it comes to driving screws, however: they’re much faster.