Choosing the Right Screw Barrel for the Extruder Machine in Snack Production

Choosing the Right Screw Barrel for the Extruder Machine in Snack Production

Importance of Choosing the Right Screw Barrel for Snack Extruder Machines

How screw barrels influence snack quality, extrusion stability, and output

The screw barrel sits at the heart of any snack extruder machine. It decides how well the final product turns out. Everything from crispiness to shape and size depends on this part. The screw pushes the raw materials forward. At the same time, it mixes, cooks, and builds pressure. If the design fits the job perfectly, snacks come out light, uniform, and tasty every single time.

A good screw barrel balances heat and shear just right. Too little energy leaves the dough under-cooked and heavy. Too much energy burns the taste or makes the pieces break easily. Modern snack lines run fast and use many different ingredients. Corn, rice, wheat, beans, and fibers all behave differently. Only the correct screw barrel keeps the line steady hour after hour. This means fewer stops, less waste, and happier customers.

Key challenges in modern food extrusion and why correct selection matters

Today’s snack makers face tough demands. Customers want clean labels and more protein or fiber. Factories want to switch recipes quickly on the same line. These changes put extra stress on the screw barrel. The wrong choice leads to sudden torque spikes, fast wear, or uneven cooking. In the worst cases, the line stops completely.

When the screw barrel matches the recipe and the machine, everything runs smoothly. Expansion stays the same from batch to batch. Texture feels perfect in every bag. That is why picking the right one is not just a technical detail. It directly affects daily production numbers and product quality.

Main Factors When Selecting a Screw Barrel for Food Extrusion

Matching screw barrel design to single-screw or twin-screw extruder machines

Start with the type of extruder you own. Single-screw machines are common for simple puffed snacks. They need strong compression and tight gaps inside the barrel. Twin-screw machines handle complex mixes and direct expanded products. They need segmented barrels and better cooling zones. Each type asks for its own geometry and material. Using the wrong style creates surging, overheating, or low output.

How raw materials and snack formulas affect screw geometry and barrel structure

Every recipe behaves in its own way. High-fiber mixes grind against the metal and wear it fast. Pure starch needs gentle but steady shear to gelatinize properly. Protein-rich doughs can burn easily if the shear is too strong. Moisture level also changes everything. Wet doughs need more mixing elements. Dry mixes need deeper flights to keep material moving.

Requirements for abrasive, fiber-rich, or starch-based ingredients

-

High-fiber blends speed up wear, so bimetallic barrels or hard alloys become necessary.

-

Starch-heavy formulas require balanced shear for full cooking.

-

Pulse-based or protein-enriched snacks need careful energy control to avoid dark spots.

Impact of moisture content and mixing needs on screw configuration

Higher moisture softens the dough and lowers friction. Screws can have more mixing paddles without overheating. Low-moisture recipes create more friction. Here, deeper channels and stronger conveying sections prevent blocking and torque peaks.

Production capacity and its relationship with L/D ratio, diameter, and compression zones

Bigger output needs longer barrels or larger diameters. A longer L/D ratio gives more time for cooking and mixing. This helps when you run difficult recipes. A larger diameter raises throughput but also raises the need for perfect cooling. Factories that move from medium to high capacity often upgrade both L/D and barrel lining at the same time. The result is lower power use and steadier running.

Material and Surface Treatment Options for Durable Screw Barrels

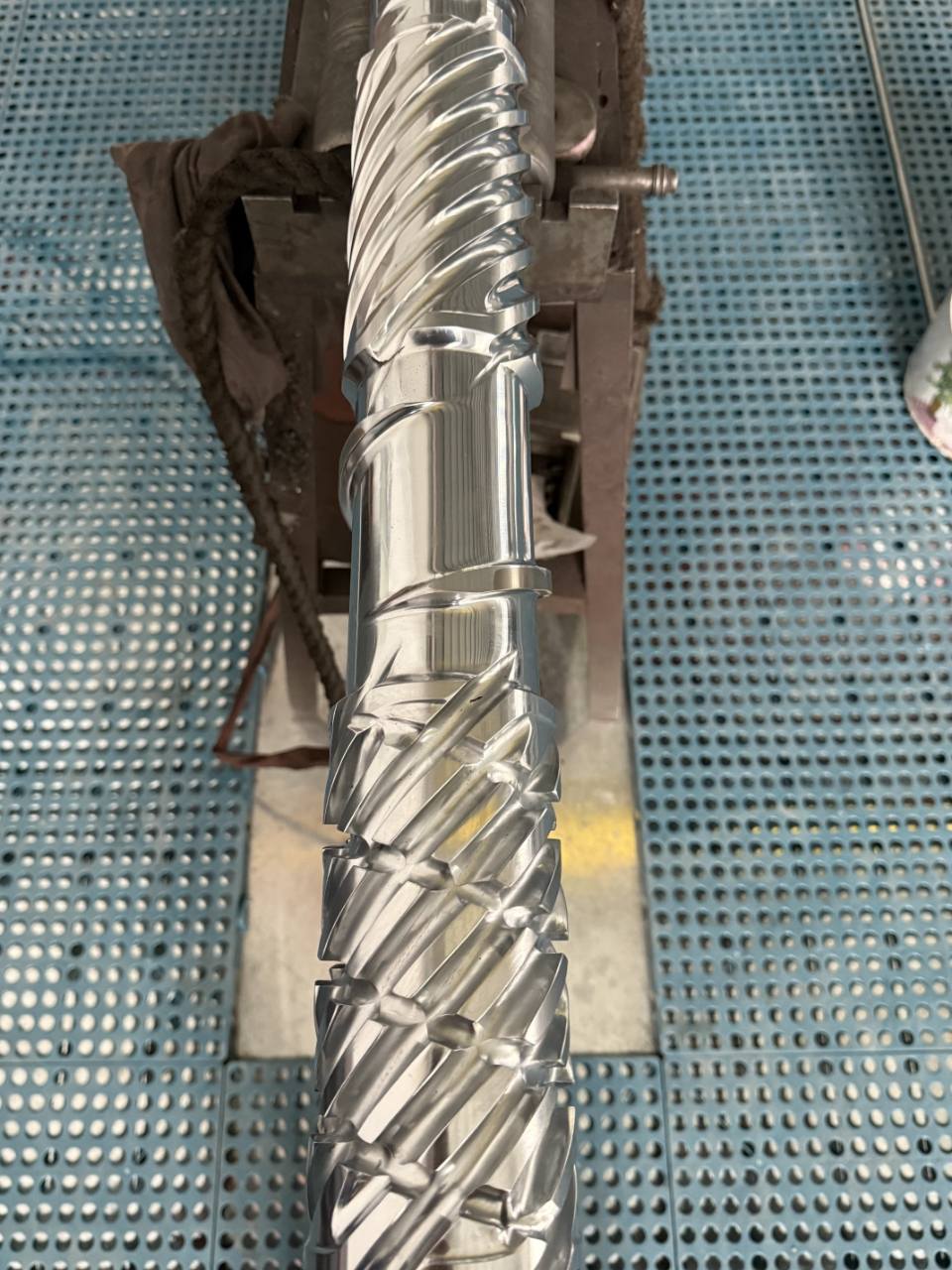

Comparing nitrided screw barrels and bimetallic screw barrels for snack production

Snack lines run many hours without stopping. Wear and corrosion appear quickly. Nitrided barrels offer good basic protection. Bimetallic barrels go much further, especially with rough ingredients.

Common materials such as 38CrMoAlA, SKD61, and alloy steels are used in extrusion

Popular base steels include 38CrMoAlA, SKD61, AISI 4140, and 42CrMo. These metals accept heat treatment well and stay tough under pressure.

Wear-resistant coatings, including HVOF and alloy welding layers

CHUANGRI SCREW uses nitriding to reach HV900–1000 hardness. For extra protection, we add HVOF tungsten carbide layers or full bimetallic liners up to 3 mm thick. These coatings fight abrasive grains and keep the barrel smooth for years.

How abrasive ingredients accelerate wear and how proper materials extend barrel lifespan

Whole grains, rice husks, or calcium additives act like sandpaper inside the barrel. Standard nitrided surfaces wear out fast. Bimetallic versions with tungsten carbide stay round and smooth much longer. One good barrel can last two or three times longer than a cheap one. This saves money on parts and reduces unplanned stops.

Total cost considerations: maintenance cycles, service life, and replacement strategies

The cheapest barrel is rarely the best deal. A high-quality screw barrel costs more at the start but pays back quickly through fewer repairs, less downtime, and steady product quality. Smart factories watch wear marks and plan replacement before problems appear.

Screw Barrel Geometry and Thermal Control for Process Optimization

Effects of screw geometry (diameter, compression ratio, L/D ratio) on mixing and expansion

Geometry decides how much energy goes into the dough. A bigger diameter moves more material. Higher compression cooks faster. Longer L/D gives better mixing and more stable puffing.

Relationship between shear, melt quality, and final snack texture

Just enough shear makes snacks light and crispy. Too much shear darkens the color and adds a burnt taste. The right screw finds the sweet spot every shift.

Geometry considerations for high-output extrusion lines

Fast lines need screws with gradual pitch changes and strong mixing zones. This keeps pressure steady even at maximum speed.

Importance of accurate barrel temperature control in food extrusion processing

A few degrees can change everything. Stable barrel temperature keeps gelatinization even and expansion predictable. Good cooling channels and strong heaters are essential.

Benefits of modular barrel sections for flexible snack production and quick recipe changes

Segmented barrels let operators change screw setup in minutes. One line can make curls in the morning and fill sticks in the afternoon without long cleaning stops.

Why CHUANGRI SCREW Is a Reliable Partner for Extruder Screw Barrel Solutions

CHUANGRI SCREW’s manufacturing expertise and global customer experience

We have over 30 years of experience and have finished more than 4,600 projects in over 30 countries. Our factory uses modern CNC machines, precise alloy treatment, and full quality checks at every step.

Customized screw barrel solutions tailored for snack extruders and food processing lines

Every customer gets a design that fits their exact recipe and machine. We adjust compression, mixing sections, and material choice to reach the best results.

High-precision machining and advanced materials to enhance extrusion performance

Our Single screw and barrel for injection machine (Φ14mm–Φ250mm) reaches HV850–1000 hardness and straightness of 0.015mm/m. The Bimetallic Screw and Barrel fights wear with thick nickel-based or tungsten-carbide layers. Our Extruder Nitride & Bimetal Screw Barrel (Φ15–Φ600) handles high output with barrier, vented, or intensive mixing designs.

In-house production, strict quality control, and fast delivery capability

Everything happens under one roof. This lets us keep quality high and ship fast, even for urgent orders.

Advantages in wear resistance, plastication efficiency, and long-term production stability

Our barrels keep tight gaps longer, deliver steady melt, and run thousands of hours with almost no trouble.

Practical Guide for Ordering Screw Barrels for Snack Extruder Machines

Technical parameters to confirm before purchasing a screw barrel

Diameter, L/D ratio, compression zones, and material selection

Always check screw diameter, barrel inside diameter, L/D ratio, compression style, surface treatment, and raw material list. These details make sure the new part fits perfectly.

Compatibility with existing extruder machine models

Wrong flange size or cooling connection causes big delays. Send your extruder model number so we can match everything exactly.

Recommended contract terms: quality inspection, warranty, delivery, and spare-parts support

Good contracts list exact hardness numbers, straightness limits, warranty months, and spare segment availability. Clear terms protect both sides.

When to upgrade or replace a screw barrel to increase snack production efficiency

Replace when you see lower output, higher power use, uneven shapes, or visible wear inside the barrel. A fresh screw barrel often brings back full speed and better quality the same day.

FAQ About Screw Barrels for Snack Production Extruders

Q: How to choose the right screw barrel for the extruder machine used in snack production?

A: Look at your recipe, moisture level, output target, and machine type. CHUANGRI SCREW helps you pick the best L/D ratio, compression, and barrel material for your exact needs.

Q: Which screw barrel materials are best for abrasive snack ingredients?

A: Our bimetallic screw barrels with tungsten carbide layers give the longest life against fiber and grain wear.

Q: What are the differences between single-screw and twin-screw extruder screw barrels for snack processing?

A: A single-screw needs strong conveying sections. Twin-screw needs modular barrels and precise mixing control. We build perfect solutions for both systems.

Q: Which brand offers reliable screw barrels for snack production extruders?

A: CHUANGRI SCREW supplies food-grade nitrided and bimetallic screw barrels trusted in over 30 countries.

Q: What signs indicate that a screw barrel for a snack extruder machine needs replacement?

A: Watch for lower output, higher torque, uneven product, visible wear marks, or rising energy use. Contact CHUANGRI SCREW for quick inspection and replacement options.