Choosing the Right Twin Screw Barrel Extruder: Key Factors to Consider

Choosing the Right Twin Screw Barrel Extruder: Key Factors to Consider

What Makes a Twin Screw Barrel Extruder Essential for Your Needs?

The Role of Twin Screw Barrel Extruders in Industrial Applications

CHUANGRI SCREW’s twin screw barrel extruders are employed in the majority of industrial operations, including plastics and polymer processing due to their superior design to allow for perfect mixing of the material and extrusion operations to achieve high-quality output in diverse industries, including packaging and automobile or pharmaceutical device manufacturing needs. The equipment is versatile and customized to process hard materials and complex formulations like PVC, PPR and HDPE with ease.

CHUANGRI SCREW’s twin screw barrel extruders are employed in the majority of industrial operations, including plastics and polymer processing due to their superior design to allow for perfect mixing of the material and extrusion operations to achieve high-quality output in diverse industries, including packaging and automobile or pharmaceutical device manufacturing needs. The equipment is versatile and customized to process hard materials and complex formulations like PVC, PPR and HDPE with ease.

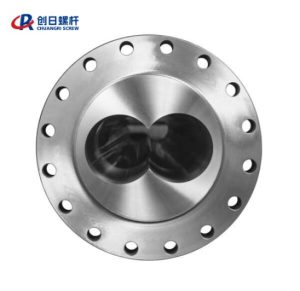

The two-screw design provides material mixing and quality control consistency in fulfilling specific demands in various industries, like recycling processes where CHUANGRI SCREW’s extruders can efficiently turn waste into usable material using their durable bimetallic barrels that are still wear-resistant and work well under tough conditions to provide consistent performance.

How Twin Screw Extruder Barrels Enhance Production Efficiency

Production efficiency is involved in industrial processing and twin screw barrel extruders are renowned for being best in class with regard to the same. Twin screw barrel extruders have a screw device that ensures smooth continuous, feeding and thorough mixing of materials yielding reduced cycle times and improved production, such as the SPC Conical Twin-Screw Barrel. CHUANGRI SCREW’s extruders stand out due to their characteristics, like enhanced temperature control and advanced structural designs, which enhance material plastification and mixing rates significantly.

Production efficiency is involved in industrial processing and twin screw barrel extruders are renowned for being best in class with regard to the same. Twin screw barrel extruders have a screw device that ensures smooth continuous, feeding and thorough mixing of materials yielding reduced cycle times and improved production, such as the SPC Conical Twin-Screw Barrel. CHUANGRI SCREW’s extruders stand out due to their characteristics, like enhanced temperature control and advanced structural designs, which enhance material plastification and mixing rates significantly.

For example, CHUANGRI SCREW’s twin screw barrels utilize SKD inner lining technology for economic processing of recycled and virgin materials. The novel design extends the screws’ life by more than 30% alongside improving uniform melting and efficient plasticizing. Besides, CHUANGRI SCREW features three-side alloy technology that dramatically improves wear resistance, thus making their extruders a perfect choice for high calcium PVC applications.

CHUANGRI SCREW’s twin screw barrels are designed for maximum production efficiency with custom screw designs addressed to material specifications in a variety of industrial environments—whether through the optimization of melt homogeneity or by facilitating quicker color changes.

How to Evaluate the Specifications of a Twin Screw Barrel Extruder?

Key Technical Parameters to Assess Before Purchase

Barrel Diameter and Length Considerations

In choosing a twin screw barrel extruder machine, one must take note of the size and length of the barrel because they impact the performance outcome. The diameter determines the quantity of material processed at the same time while the length-to-diameter (L/D) ratio determines the melting and mixing processes. CHUANGRI SCREW provides diameter sizes ranging from 50mm to 800mm with L/D ratios that can be customized depending on the particular application needs. Their screw barrels with a parallel design have ratios of length to diameter, ranging from 18 to 40 units to cater to various processing needs effectively for tasks, involving common plastics or those with high calcium content.

Material Compatibility and Wear Resistance

Material compatibility assessment is one aspect of assessing twin screw barrels’ capacity for performance. Material selection for construction indirectly sets limits on how well equipment can process harsh or corrosive materials and still be durable. CHUANGRI SCREW employs quality materials such as 38CrMoAlA and SKD61 in the construction of their barrels and complements them with surface treatment, nitriding and bimetallic coating included.

Such improvements are corrosion and wear-resistant and are most effective to be used with hard materials such as heavily filled resins or PVC filled with calcium carbonate. Moreover, CHUANGRI SCREW employs HVOF tungsten coatings in order to meet the demands of applications requiring maximum longevity.

![]()

Customization Options for Specific Requirements

![]()

![]()

![]() Tailoring solutions to meet production requirements is crucial in the manufacturing industry’s modern landscape. CHUANGRI SCREW stands out for its ability to provide solutions that cater to individual operational objectives effectively. Whether it involves adjusting screw designs or integrating coatings, such as chromium or titanium plating, CHUANGRI SCREW’s customization expertise guarantees the peak performance of the equipment. Their tapered double screw barrels can be customized with dual-layer alloy coatings in high-wear areas specifically tailored for WPC boards or SPC flooring production processes. This technique not only increases the standard of products but also extends the lifetime of the machines significantly.

Tailoring solutions to meet production requirements is crucial in the manufacturing industry’s modern landscape. CHUANGRI SCREW stands out for its ability to provide solutions that cater to individual operational objectives effectively. Whether it involves adjusting screw designs or integrating coatings, such as chromium or titanium plating, CHUANGRI SCREW’s customization expertise guarantees the peak performance of the equipment. Their tapered double screw barrels can be customized with dual-layer alloy coatings in high-wear areas specifically tailored for WPC boards or SPC flooring production processes. This technique not only increases the standard of products but also extends the lifetime of the machines significantly.

What Are the Maintenance and Longevity Tips for Your Twin Screw Barrel?

Best Practices for Prolonging the Life of Your Twin Screw Extruder Barrel

Screw extruders should be kept in the best possible condition by following the correct cleaning procedures so that their effectiveness and lifespan are properly ensured in the long run. Buildup of residue should not be permitted as it can result in barrel system wear and extruder performance loss.

For cleaning your twin screw barrel, use soft tools that will not end up in any scratches or damage to the inner barrel surface. Keep off brushes and sharp objects that may interfere with the integrity of the barrel lining. Try cleaning solutions that are formulated for plasticizing equipment because they will clean residues without destroying the coatings of your twin screw barrel.

In addition, CHUANGRI SCREW also provides customization choices for replacing screws and barrels, allowing you to align with operational needs. Whether you require a nitrided screw for applications or a bimetallic alternative for dealing with harsh substances.

Why Should You Choose CHUANGRI SCREW’s Twin Screw Barrel Extruder?

Unique Features of CHUANGRI SCREW’s Twin Screw Barrel Products

CHUANGRI SCREW is particularly committed to the use of high-quality materials in the production of its screw barrel extruders. Advanced alloys such as 38CrMoAlA, SKD61 and CPM 10v are employed by the company for durability and anti-wear, such as the Parallel Twin-Screw Barrel. Its materials are further supported by surface treatments such as nitriding, bimetallic coatings and HVOF tungsten carbide coatings. The nitrification process creates a hardness of 65–70 HRC making the screws highly resistant to wear even in severe operating conditions.

CHUANGRI SCREW is particularly committed to the use of high-quality materials in the production of its screw barrel extruders. Advanced alloys such as 38CrMoAlA, SKD61 and CPM 10v are employed by the company for durability and anti-wear, such as the Parallel Twin-Screw Barrel. Its materials are further supported by surface treatments such as nitriding, bimetallic coatings and HVOF tungsten carbide coatings. The nitrification process creates a hardness of 65–70 HRC making the screws highly resistant to wear even in severe operating conditions.

CHUANGRI SCREW’s bimetal barrels are extremely strong and can well withstand corrosion. The barrels are equipped with an even dispersion of carbide alloy liner in a corrosion-resistant nickel matrix. This offers the optimal performance under conditions, with abrasives and corrosive components, and renders them the best choice for handling hard materials, like PVC containing high amounts of calcium carbonate or highly filled resins.

CHUANGRI SCREW incorporates design elements in its dual screw barrel extruders to enhance efficiency. Their conical screw barrels come with SKD inner lining technology that boosts the durability of the screws by more than 30%. This innovation guarantees melting and efficient plasticizing performance when working with new and recycled materials alike.

They have introduced an creative element by incorporating three side alloy technology into their designs that boosts durability while still ensuring great material blending capabilities—a feature especially advantageous for tasks that demand accurate quality management, like crafting WPC boards or SPC flooring products.

The Benefits of Using CHUANGRI SCREW’s Twin Screw Barrel Extruders

Improved Productivity with Precision Engineering

CHUANGRI SCREW’s double screw barrel extruders are designed to boost efficiency. The two-screw setup allows for seamless material feeding and thorough blending, resulting in production cycles and higher yields. These extruders also feature temperature control systems that improve material melting rates while reducing energy usage.

The meticulous craftsmanship involved in these extruders also plays a part in enhancing the quality of the products they produce. They incorporate structural layouts, like barrier zone setups to improve the consistency of the molten material and decrease strain during production. This leads to product outcomes with few imperfections.

Frequently Asked Questions about Twin Screw Barrel Extruder

Q: What are the disadvantages of twin screw extruders?

A: Twin-screw extruders disadvantages in food processing:

Higher cost: Both the capital expenditure and the operation cost are higher.

Complexity: Twin-screw extruder is mechanically more complicated and less robust. Consequently, the machine is more mechanically subject to abuse (e.g., excessive torque).

Q: What is the difference between a twin screw extruder and a single screw extruder?

A: Twin-screw extruders are advantageous over single-screw extruders, especially in demanding applications like compounding and mixing, due to their improved mixing, higher throughput, and screw wear compensation. Single-screw extruders, although simpler and less expensive, work well in straightforward extrusion applications where precise mixing is not as critical.

Q: How much energy does a twin screw extruder use?

A: For the twin screw extruder, the measured power (motor energy) increased linearly with screw speed from about 1.02 kW to 1.71 kW.

Q: Why use a twin screw extruder?

A: Twin-screw extruders are preferable to single-screw extruders in most instances since they mix better, possess greater flexibility to handle different materials, have higher capacity, and are more consistent in product quality. Their intermeshing nature allows for finer and more efficient material mixing, especially when using additives or pigments. They can also handle a wider material range and are better suited for handling materials with different viscosities.