Comparative Analysis of Injection Moulding Machine Screw Barrel Technologies

Comparative Analysis of Injection Moulding Machine Screw Barrel Technologies

Overview of Injection Moulding Machine Screw Barrel Technologies

Injection moulding machine screw barrel technologies are key to working with plastics. They decide how well raw materials get melted, mixed, and pushed into molds. The screw and barrel team up to move, melt, and measure the material. Their design affects output, melt quality, and how long they last. Industries like cars, electronics, packaging, and medical tools depend on these parts for steady, high-quality products.

Key things that matter include:

-

Output capacity: More output means faster work.

-

Wear and corrosion resistance: Tough parts last longer.

-

Melt homogeneity: Even melt makes better products.

-

Dimensional accuracy: Exact sizes ensure parts fit molds correctly.

Types of Injection Moulding Screw and Barrel Designs

Different designs handle various material challenges.

Single Screw and Barrel for Injection Machines

Single-screw barrels are common for everyday plastics like PP, PE, ABS, and PET. They’re simple and work well for medium jobs. CHUANGRI SCREW Nitrided Injection Molding Screw is built with a nitrided layer of 0.5–0.8 mm. It reaches hardness up to HV900–1000. This gives good wear resistance and keeps costs low.

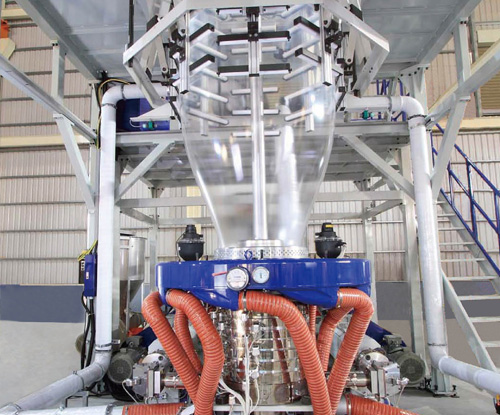

Parallel Twin-Screw and Conical Twin-Screw Barrels

Twin-screw barrels mix better and boost output for tough jobs. Parallel twin-screws give steady melt flow and even mixing. Conical twin-screws are made for PVC, SPC, and WPC products. CHUANGRI SCREW Conical Twin-Screw Barrel handles up to 300% calcium carbonate filler. It keeps plasticizing steadily, even with heavily filled materials.

Bimetallic, Nitrided, and Solid Carbide Screw Barrel Variants

Special designs fit specific needs:

-

Bimetallic Injection Molding Screw: Has tungsten carbide alloy layers to fight abrasive fillers.

-

Solid Carbide Screw: Great for plastics with up to 75% glass fiber.

-

Nitrided screws and barrels: Affordable for common plastics with decent wear resistance.

Materials and Coating Technologies for Screw Barrels

The materials and treatments you pick decide how long screw barrels last.

Common Alloy Materials: 38CrMoAlA, SKD61, and High-Nickel Steels

Common alloys like 38CrMoAlA and 42CrMo are strong and handle heat well. For rough settings, high-nickel alloys like Inconel and Hastelloy C-276 fight corrosion nicely.

Nitriding, Bimetallic Layer, and Quenching Processes Explained

-

Nitriding: Makes a hard layer 0.5–0.8 mm thick, hitting HV900+ hardness.

-

Bimetallic liners: Use centrifugal casting to spread tungsten carbide evenly. They reach up to 62 HRC hardness.

-

Quenching and tempering: Keep hardness at HB260–290 for toughness.

Advanced Coatings: Chromium Plating, Tungsten Carbide, and Titanium

Coatings improve surface strength:

-

Chromium plating: Adds a 10–50 μm layer for wear resistance and smoothness.

-

Tungsten carbide coatings: Stand up to rough fillers.

-

Titanium plating: Works well in corrosive, hot settings.

These treatments make parts last longer and cut downtime.

Comparative Analysis of Screw Barrel Technologies

Wear and Corrosion Resistance Performance Comparison

| Technology | Wear Resistance | Corrosion Resistance | Typical Use Cases |

| Nitrided Screw Barrel | Medium | Medium | General-purpose plastics |

| Bimetallic Screw Barrel | High | High | PVC, filled resins, glass fiber |

| Solid Carbide Screw | Very High | Very High | Reinforced engineering plastics |

This shows bimetallic and carbide options are tougher for rough or corrosive settings. Nitrided designs work for budget-friendly, standard jobs.

Cost Efficiency and Service Life of Screw Barrel Options

Bimetallic and carbide barrels last longer than nitrided ones. They cost more upfront but save money by needing less maintenance and fewer unexpected stops.

Productivity and Melt Homogeneity in Applications

CHUANGRI SCREW’s high-speed blown film screws give 20% more output than older designs. Not every job sees this boost, but better designs improve melt temperature control and film evenness. This helps a lot in film extrusion and packaging.

Trends and Innovations in Screw Barrel Manufacturing

CNC Machining Precision and Automated Inspection Systems

CNC lathes, thread milling, and 5-axis machines ensure super-precise parts. Tools like coordinate measuring machines (CMM) and hardness testers check fit, alignment, and strength before shipping.

High-Speed Processing and Energy Efficiency Trends

New shapes from CHUANGRI SCREW Screw speed up work and mix melts better. This means less energy is used per kg of plastic, which is great for manufacturers.

Sustainability and Recycling Applications with Screw Barrels

The push for recycling has led to special screw barrels. CHUANGRI SCREW Recycling Pelletizing Screws use nickel-based alloys and tungsten carbide layers. They keep output steady when working with waste plastics. These designs cut material waste and support eco-friendly production.

CHUANGRI SCREW Barrel Solutions and Advantages

At CHUANGRI SCREW, we make custom screw barrel solutions for industry needs. Since 1990, we’ve done over 4,600 projects and shipped to more than 30 countries.

Customized OEM & ODM Design Capabilities

We offer OEM/ODM solutions that work with all major injection moulding brands. Our R&D team uses CAD and SolidWorks to tweak screw shapes for specific jobs.

Production Process Flow: From Alloy Selection to Final Assembly

Our process ensures tough, precise parts:

-

Material preparation: We use ultrasonic flaw detection.

-

Machining: Done with CNC turning, thread milling, and honing.

-

Heat treatment: Includes nitriding or quenching.

-

Inspection: Checks hardness, size accuracy, and surface finish.

-

Protective packaging: Uses anti-rust oil and wooden crates.

Proven Case Studies in Automotive, Pipe, and Recycling Applications

-

Nitrided Injection Molding Screw: Used for consumer goods and toys.

-

Bimetallic Injection Molding Screw: Picked for car plastics with glass fiber, fighting wear.

-

Solid Carbide Screw: Needed for electronics with high-strength plastics.

FAQ

Q: What is the typical lifespan of a nitrided vs. a bimetallic injection moulding screw barrel?

A: Nitrided barrels work for standard plastics but wear out faster in tough conditions. Bimetallic barrels, with alloy layers, last much longer.

Q: How to choose the right injection moulding screw barrel for high-glass fiber plastics?

A: For glass-fiber plastics, a Solid Carbide Screw from CHUANGRI SCREW is best. It handles high wear without losing performance.

Q: Are injection moulding screw barrels interchangeable across machine brands?

A: Yes. CHUANGRI SCREW makes OEM/ODM barrels that fit various global machine models, ensuring a good fit and performance.

Q: What is the difference between an injection moulding screw barrel and an extruder screw barrel?

A: Injection barrels are for batch processing and precise shots. Extruder barrels give steady melt flow for films, pipes, or sheets.

Q: Which companies are known for reliable injection moulding screw barrel solutions?

A: CHUANGRI SCREW is trusted worldwide for precise CNC machining, ISO 9001:2008 quality, and proven results in over 30 countries.