Decoding the Barrel Single Screw Extruder: Crucial Elements Unveiled

Decoding the Barrel Single Screw Extruder: Crucial Elements Unveiled

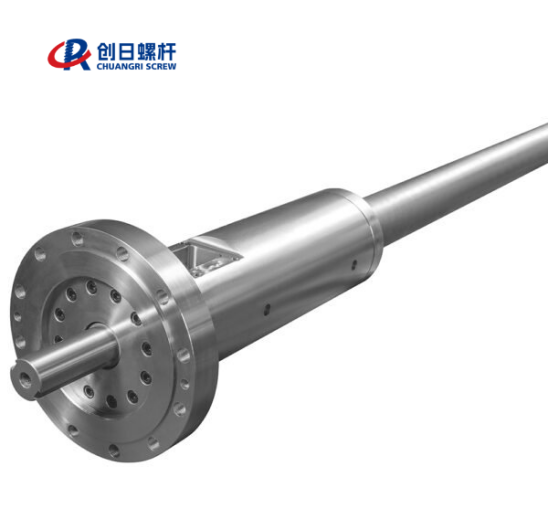

Plastic processing is a big deal in many industries. The barrel single screw extruder is a top tool for this job. It’s super handy for making things like plastic pipes or packaging films. It’s flexible and works well. This article breaks down the key parts that make this machine so great. It also shows how CHUANGRI SCREW offers special solutions for all kinds of extrusion needs.

Introduction to Single Screw Extruders

What is a Single Screw Extruder?

A single screw extruder is a machine that melts and shapes plastic. It has one spinning screw inside a barrel. The screw pushes plastic into the barrel. Heat and pressure turn the plastic into a smooth mix. Then, the mix goes through a mold to make shapes like pipes or sheets.

Key Applications in Plastic Manufacturing

Single screw extruders are vital in lots of fields. They’re used in cars, buildings, packaging, and even medical stuff. They make things like PVC pipes, wire covers, and food wrap. They handle many materials and keep output steady. This makes them a must for big production setups.

The Mechanics of a Barrel Single Screw Extruder

How the Single Screw and Barrel Work Together

The screw and barrel team up to make the extruder work great. The screw spins and does three main jobs:

- Solid Conveying: It moves the material through the barrel.

- Melting: Heat and rubbing melt the plastic as it travels.

- Metering and Pumping: It controls the flow to keep it even as it leaves the mold.

The barrel is just as important. It has different zones. Each zone handles a part of the process, from feeding to final shaping.

The Role of Heat and Friction in Plasticizing Materials

Melting plastic is a big part of what the extruder does. Heat comes from outside heaters on the barrel. Rubbing from the spinning screw also helps. For plastics like PVC, PE, and PET, this melting makes sure the final product is smooth and high-quality.

Understanding the Three Zones of a Single Screw Extruder

A single screw extruder has three key zones:

- Feeding Zone: Plastic goes in here. The screw starts moving.

- Compression Zone: The plastic gets squished and begins to melt.

- Metering Zone: The plastic is fully melted and ready to flow out.

Each zone matters a lot. They make sure the plastic moves smoothly and melts without breaking down.

Key Components of a Barrel Single Screw Extruder

Screw Design: Types and Functions

The screw is super important. It moves, melts, and pumps the plastic. Its design changes based on the job or material. There are three main types: barrier screws, solid screws, and pin-type screws. Each is built for specific materials or results.

Barrel Design: Variations for Different Materials

The barrel needs to be tough. It handles high heat and pressure. It also keeps the plastic flowing smoothly. Some barrels have special coatings, like bimetallic ones. These fight wear and rust, especially for rough or filled materials. CHUANGRI SCREW‘s Bimetallic Screw and Bimetallic Barrel is awesome for tough plastics and high-filler stuff. It lasts longer and works better.

Feed Section: Enhancing Material Flow and Output

The feed section controls how plastic enters the barrel. The screw design here is key. It keeps the flow steady and even. This affects how well the extruder works and how good the final product is.

Screw Speed and Torque: Optimizing Performance

Screw speed and torque are big factors. They help process materials well. The right settings save energy and reduce wear. CHUANGRI SCREW‘s custom solutions balance speed and torque. This boosts output and cuts costs.

Advantages of Barrel Single Screw Extruders

Efficiency and Versatility in Plastic Processing

Single screw extruders are super flexible. They work with lots of plastics, like polyolefins, styrenes, and tough engineering plastics. This makes them great for many industries. You can tweak the design for specific needs, which makes them work even better.

Enhanced Output with Minimal Energy Consumption

CHUANGRI SCREW’s products are built for high output. They use less energy. They are perfect for big operations. They save money on power while keeping quality steady.

Customization for Specific Industrial Applications

Every job has its own needs. Materials and output goals vary. CHUANGRI SCREW makes custom solutions. They ensure top performance, whether you’re working with high-filler plastics or need specific heat and pressure settings.

Common Issues and How to Address Them

Wear and Tear on the Screw and Barrel

Screws and barrels wear out over time. This happens a lot with rough or high-filler plastics. CHUANGRI SCREW fixes this with Bimetallic Screws and Alloy Coating. These are super tough and last longer.

Overheating and Material Degradation

Too much heat can ruin plastic. It leads to poor quality. CHUANGRI SCREW uses bimetallic coatings and nitriding to control heat. This keeps the plastic in good shape during processing.

Solutions for Extended Equipment Life

CHUANGRI SCREW uses advanced materials and coatings. These make equipment last longer. Their Extruder Nitride & Bimetallic Screw Barrel is great for tough jobs. It keeps working well even under stress.

Best Practices for Maintaining Barrel Single Screw Extruders

Routine Maintenance: Ensuring Longevity

Regular checks keep your extruder in top shape. Look for wear. Make sure cooling systems work right. Replace worn parts like screws or barrels when needed.

Choosing the Right Materials for Optimal Performance

Picking the right materials for screws and barrels is key. It helps the extruder work well. CHUANGRI SCREW offers options like 38CrMoAlA, AISI 4140, and SKD61. These fit specific job needs.

Upgrading Screws and Barrels for Better Output

Better screws and barrels can boost performance. CHUANGRI SCREW’s custom designs help a lot. They make sure the extruder fits your exact needs.

FAQ

Q: What are the benefits of using a single screw extruder over a twin-screw extruder?

A: Single screw extruders are simpler and cheaper. They work great for many materials. They’re awesome for basic jobs. Twin-screw extruders are better for mixing or complex tasks.

Q: How do I know if my extruder needs a screw upgrade?

A: Look for uneven output or high energy use. If the plastic breaks down, it’s time for a new screw. CHUANGRI SCREW offers custom designs to improve output and save money.

Q: Can a single screw extruder handle high-filler materials?

A: Yes, with the right setup. CHUANGRI SCREW’s Bimetallic Single Screw is built for tough, high-filler plastics. It fights well.

Q: What is the role of the metering zone in a single screw extruder?

A: It keeps pressure and flow steady as plastic goes to the mold. This ensures the product comes out great.

Q: How can I reduce wear on my screw and barrel?

A: Use tough coatings like bimetallic layers or nitriding. CHUANGRI SCREW’s solutions make equipment last longer.