Enhancing Durability of Extruder Screws and Barrels: An In-depth Guide

Enhancing Durability of Extruder Screws and Barrels: An In-depth Guide

Key Factors Influencing Extruder Screw and Barrel Durability

Extruder barrels and screws’ durability affects product quality, work productivity, and overall cost. Their durability depends on material choice, surface finishes, and precise shape. The above factors are inextricably linked to determine the degree to which they can survive wear, heat, and chemical exposure in continuous extrusion.

Extruder Screw Material Selection for Long-Term Wear Resistance

Picking the right material is the core of screw and barrel durability. Most strong extruder screws use 38CrMoAlA, 42CrMo, or SKD61 (H13) alloy steels. Each is chosen for its toughness and heat resistance.

| Material | Typical Application | Key Benefit |

| 38CrMoAlA | PE, PP, ABS, general plastics | Excellent machinability, nitriding response |

| 42CrMo | Glass-fiber reinforced polymers | High toughness, fatigue strength |

| SKD61 (H13) | High-temperature and engineering resins | Superior heat resistance and wear life |

To extend lifespan, modern designs add bimetallic layers or solid carbide surfaces. These greatly boost resistance to abrasive fillers or compounds.

Surface Treatment Technologies to Improve Screw and Barrel Hardness

Even top alloys need surface hardening for full wear protection. Common methods include gas or plasma nitriding, hard chrome plating, and tungsten carbide coating.

-

Nitriding builds a hard layer (0.5–0.8 mm thick, HV900–1000). It fights mechanical wear.

-

Hard chrome plating gives a smooth surface. This cuts polymer sticking.

-

Tungsten carbide coatings, applied by HVOF thermal spray or PTA welding, resist both wear and corrosion.

The best method depends on the polymer and filler amount. For instance, nitriding suits PE and PP extrusion. Carbide coatings work better for PVC or glass-filled materials.

Screw Geometry and Barrel Design Optimization for Longevity

Durability relies on more than materials. It also depends on shape. The flight depth, compression ratio, and metering section affect how evenly stress and heat spread along the screw.

Modern screw designs feature:

-

Rounded root corners to reduce stress buildup.

-

Even compression zones to control melt heat.

-

Special barrier sections for consistent mixing.

Precise machining keeps the screw and barrel aligned. This avoids side-load wear. Maintaining this balance slows material damage and mechanical tiredness.

Maintenance and Inspection Strategies to Extend Extruder Screw and Barrel Life

Steady upkeep is the cheapest way to protect extruder parts. Regular checks, cleaning habits, and controlled settings can add years to screw and barrel life.

Regular Inspection and Dimensional Wear Monitoring

Wear builds slowly and can be tracked with careful measurement. Checking the screw outer diameter (OD) and barrel inner diameter (ID) shows clearance changes over time.

If clearance goes past 0.3–0.4 mm, melt compression weakens. This causes uneven output. Tools like coordinate measuring machines (CMMs), bore gauges, or hardness testers help plan upkeep. This reduces sudden downtime.

Cleaning and Purging Practices for Extruder Screw and Barrel Maintenance

Contamination is a main cause of early wear. During material switches, leftover polymers must be cleaned well. Suggested practices include:

-

Use copper or brass tools instead of steel to avoid scratches.

-

Applying purging compounds before changing materials.

-

Avoiding quick cooling that causes heat stress.

Smooth barrel finishes (surface roughness ≤ Ra 0.4 µm) cut residue buildup. This simplifies cleaning cycles.

Optimizing Operating Parameters to Reduce Screw and Barrel Wear

Extruder performance depends on work conditions. Too much stress, uneven RPM, or overheating can shorten part life.

Industry reports show stable melt heat and torque within design limits can boost screw life by up to 20%. This comes from field data by major plastic processors. Even heat zones and slow startup speed help prevent local wear.

Refurbishment, Rebuild, or Replacement of Worn Extruder Components

When wear appears, the right fix depends on its level:

-

Small wear (<0.1 mm): Surface polishing or light grinding.

-

Medium wear: Overlay welding or bimetallic spray coating.

-

Heavy damage: Full replacement to restore tolerance and output.

Well-fixed screws often regain 85–90% of their original performance. This delays costly replacements.

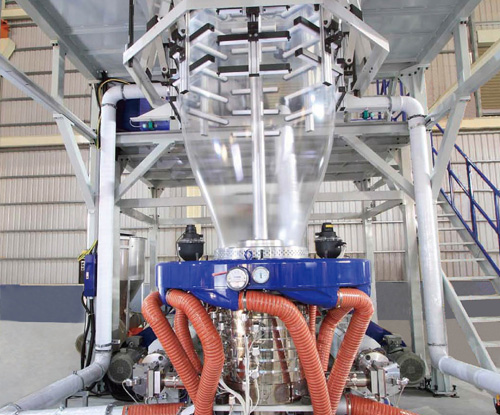

Advanced Engineering Solutions for Enhancing Extruder Screw and Barrel Durability

New extrusion technology blends advanced metalwork, surface science, and data-driven upkeep. These improve output efficiency and extend lifespan.

Bimetallic and Solid Carbide Screw Barrel Technology

Bimetallic barrels are standard for tough tasks. A nickel-based alloy or tungsten carbide liner, bonded to a steel shell, handles fillers over 35% without bending.

Solid carbide screws suit abrasive polymers like glass-filled PA or flame-retardant compounds. They reach a hardness of up to 70 HRC. These screws maintain shape accuracy under constant high stress and heat.

Innovative Coating and Surface Engineering Technologies

New nano-composite coatings and ceramic-metal hybrids offer self-lubricating and crack-resistant traits. Centrifugal casting creates a dense, even structure. This stops peeling, a common issue in standard coatings.

These treatments extend wear life and cut color-change times and purging needs. This boosts production efficiency.

Predictive Maintenance Systems for Extruder Screw and Barrel Health Monitoring

Digital monitoring changes how extrusion lines are kept up. Sensors track stress, vibration, and heat. Predictive tools spot wear before it causes process issues.

Reports from Society of Plastics Engineers (SPE) conferences note that plants using predictive upkeep cut sudden stops by about 20–25%. This shows that condition-based monitoring saves more than reactive fixes.

Case Studies and Material-Based Selection Guide for Extruder Screw and Barrel Durability

Different polymers and additives create unique stresses on extruder parts. Choosing the right setup based on material behavior improves efficiency and lifespan.

Comparing Wear Resistance Solutions Across Different Extrusion Applications

| Application | Recommended Design | Average Life Improvement |

| Glass-Filled Polypropylene | Solid Carbide Screw | +40–45% |

| PVC with High Calcium Carbonate | Bimetallic Conical Twin-Screw Barrel | +30–35% |

| Recycled PE/PP Compounds | Alloy-Coated Pelletizing Screw | +25–30% |

These results come from real plant data. They optimized materials and coatings for specific production settings.

Choosing the Right Screw and Barrel Design for Your Extrusion Process

When picking or upgrading screws and barrels, consider work conditions and upkeep ability:

-

Abrasive fillers (glass, minerals): Tungsten carbide or solid carbide solutions.

-

Corrosive materials (PVC, fluoropolymers): Nickel-based bimetallic liners.

-

Standard applications: Nitrided 38CrMoAlA is cost-effective and reliable.

Matching material choice with production settings leads to steady wear patterns. This ensures even melt performance and avoids early part fatigue.

CHUANGRI SCREW’s High-Durability Extruder Screw and Barrel Solutions

Precision Engineering and Material Expertise

With over 30 years of experience, CHUANGRI SCREW focuses on exact design and production of extruder screws and barrels. Each part uses advanced CNC machining, heat treatment, and bimetallic alloying. This ensures strong wear resistance and shape stability under high load.

Durability-Focused Product Range

Our main products—Bimetallic Barrel, Solid Carbide Screw, and Nitrided Screw and Barrel—are built for tough extrusion tasks. These include PVC, WPC, and high-filler polymers. The mix of high-performance alloys and optimized shapes ensures longer life and steady melt quality.

Proven Industrial Performance

Used in over 4,600 global projects, CHUANGRI SCREW’s solutions consistently cut upkeep needs and extend service intervals. They maintain high output efficiency, offering reliable performance in ongoing production settings.

FAQ

Q: How can I increase the lifespan of an extruder screw and barrel?

A: Use wear-resistant alloys, keep steady work settings, and do regular checks. Cleaning with non-metal tools and purging compounds prevents residue buildup that speeds wear.

Q: What materials are best for high-filler extrusion lines?

A: Tungsten carbide and nickel-based bimetallic alloys give top resistance to abrasion from glass fiber, minerals, or flame retardants.

Q: What’s the difference between nitrided and bimetallic barrels?

A: Nitrided barrels suit standard resins. Bimetallic barrels offer higher wear and corrosion protection for filled or high-stress tasks.

Q: When should worn extruder components be replaced?

A: Replace when clearance exceeds 0.3–0.4 mm or output stability drops. Moderate wear can often be fixed with overlay welding or regrinding.

Q: What are the early signs of screw or barrel wear in extrusion lines?

A: Signs include uneven pressure, inconsistent melt heat, higher motor load, or visible streaks in products. These show that shape accuracy is weakening.