The Science Behind Bimetallic Screw Barrel Durability and Longevity

The Science Behind Bimetallic Screw Barrel Durability and Longevity

What Drives Durability in a Bimetallic Screw Barrel

Bimetallic screw barrel durability is not accidental—it is the result of deliberate material engineering and process-driven design choices. In plastic extrusion and injection molding, the screw and barrel operate under continuous mechanical load, high temperatures, and aggressive material environments. Understanding why bimetallic designs outperform conventional barrels starts with recognizing that durability is a system-level outcome, not a single-material advantage.

From a processing perspective, a bimetallic screw barrel is engineered to handle long production cycles, abrasive fillers, and chemically active polymers without rapid dimensional loss. Unlike traditional nitrided barrels that rely on surface hardness alone, bimetallic barrels combine a tough steel substrate with a highly wear-resistant alloy liner. This layered structure allows the barrel to resist wear while maintaining structural integrity over extended service life.

Material Synergy Behind a Bimetallic Screw Barrel

Bimetallic screw barrel performance relies on how various materials team up. They do not fight each other. The outer steel body gives mechanical strength, stiffness, and protection against bending under force. The inner alloy liner, though, is what really sets durability.

In factory settings, this teamwork lets the liner take on abrasion and rust. Meanwhile, the base material holds the shape steady. As a result, the barrel keeps an even spacing with the screw. This ensures steady output and melt quality. It holds up even after thousands of hours of use. Such reliability matters a lot in tasks where steady processes affect product quality.

Wear, Corrosion, and Thermal Stress in Real Processing Conditions

Bimetallic screw barrel longevity depends on actual stress factors in the field. It does not rely on lab guesses. Rough fillers like calcium carbonate, glass fiber, or waste bits keep scraping the barrel surface. At the same time, harmful gases from polymer breakdown attack the metal at high heat levels.

Heat stress brings extra challenges. Cycles of heating and cooling lead to swelling and shrinking. This can speed up tiny cracks if the materials do not match well. A well-made Bimetallic Barrel reduces these dangers. It balances hardness, strength, and heat matching. This balance is key for reliable long-term use.

Bimetallic Screw Barrel Wear Mechanisms Explained

Bimetallic screw barrel wear mechanisms involve many sides. They link closely to how materials move. Each wear type affects the barrel surface in its own way. Knowing these helps users make smart choices.

Abrasive Wear in High-Filler and Glass-Fiber Compounds

Abrasive wear is the main failure type in bimetallic screw barrels for filled plastics. Hard bits scrape the barrel wall over and over. They remove material bit by bit through small cuts and furrows. In time, this wear widens the gap. It cuts shear power and harms output steadiness.

Bimetallic barrels fight this issue. They embed hard parts, such as tungsten carbide, in a rust-proof alloy base. This setup spreads out the wear forces. It also slows down material loss. Thus, bimetallic barrels fit well for PVC, engineering plastics, and recycled items with lots of fillers.

Corrosive and Chemical Degradation in Polymer Processing

Corrosion wear in a bimetallic screw barrel often stays hidden until output falls a lot. Some polymers give off acid leftovers during work. Flame retardants and extras can make the chemical harm worse. Unlike abrasive wear, corrosion eats at the metal on a tiny scale.

Nickel-based alloy liners in bimetallic barrels offer good defense against chemical harm. They create steady oxide covers. These stop harsh agents from digging deeper into the material. So, the barrel lasts longer even in tough chemical spots.

Thermal Fatigue and Mechanical Stress Over Long Service Life

Thermal fatigue poses a slow danger to bimetallic screw barrel longevity. Steady changes in temperature create repeating stress. This can cause cracks from tiredness if the liner and base expand at different speeds. Pressure buildup adds to the problem mechanically.

Modern bimetallic designs tackle thermal fatigue. They match heat expansion rates closely. They also ensure a solid metal bond between layers. This cuts internal stress. It stops early liner breakdown during long runs.

How Bimetallic Barrel Manufacturing Impacts Longevity

Bimetallic screw barrel durability ties closely to manufacturing methods. It goes beyond just picking materials. The way it is made sets the liner’s density, bond strength, and lasting steadiness.

Centrifugal Casting vs Spray Welding for Bimetallic Liners

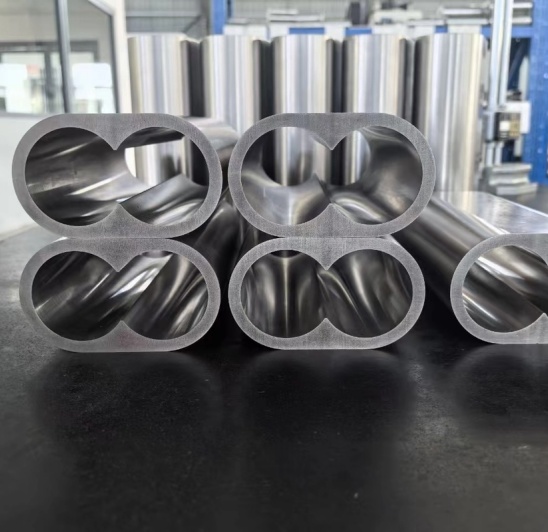

Manufacturing technique plays a decisive role in bimetallic screw barrel performance. Centrifugal casting produces a dense, uniform liner by forcing molten alloy against the barrel wall under high rotational speed. This process minimizes porosity and ensures consistent thickness throughout the bore.

Spray welding, while suitable for localized reinforcement, may introduce variations in density and bonding quality if not precisely controlled. For applications demanding maximum lifespan and uniform wear resistance, centrifugal casting offers superior reliability.

Alloy Composition and Carbide Distribution in Bimetallic Barrels

The inner structure of a bimetallic screw barrel decides how well it fights wear. Alloy makeup controls rust resistance. Carbide size and spread affect scrape resistance. A good mix is vital.

Too-big carbides lead to weakness. Too few carbides cut wear fight. Smart bimetallic barrels spread carbides evenly in a strong base. This gives both hardness and hit resistance. Such traits support steady, long-term work.

Machining Precision and Clearance Control Between Screw and Barrel

Precision machining is essential for maintaining bimetallic screw barrel longevity. Even the most advanced materials cannot compensate for poor concentricity or inconsistent surface finish. Tight tolerances ensure stable clearance, reducing localized wear and energy loss.

At CHUANGRI SCREW, CNC machining and rigorous inspection processes are used to achieve smooth bore finishes and accurate alignment. This precision directly translates into lower wear rates and longer service intervals.

Evaluating Bimetallic Screw Barrel Longevity in Industrial Use

Bimetallic screw barrel service life varies widely depending on application, making evaluation a critical step in the decision-making process. A realistic assessment considers both operating conditions and long-term operational goals.

Service Life Expectations Under Different Processing Scenarios

Bimetallic screw barrel lifespan fits specific uses. In basic plastics, a bimetallic barrel may show small gains. But in rough or rusting spots, life can grow a lot. Often by 30% or more than nitrided barrels.

For instance, handling recycled plastics or high-calcium PVC stresses the barrel surface hard. In those cases, bimetallic options are not just extras. They are must-haves for steady making.

Total Cost of Ownership vs Initial Investment

Total cost of ownership means more than the starting price for a bimetallic screw barrel. Longer life cuts stop times, fix work, and swap needs. These gains usually beat the higher first cost.

From a business view, better durability steadies making plans. It also lowers the risks of surprise halts. This counts for lines with high output.

When Bimetallic Screw Barrels Are Not the Optimal Choice

Bimetallic screw barrels are not universally required. In low-wear applications with clean, unfilled polymers, nitrided barrels may provide sufficient performance at lower cost. Overengineering can lead to unnecessary expenditure without proportional benefit.

A proper evaluation balances material characteristics, throughput requirements, and expected service life to select the most appropriate solution.

Engineering Bimetallic Screw Barrel Solutions at CHUANGRI SCREW

At CHUANGRI SCREW, bimetallic screw barrel engineering targets exact wear and life issues. We do not sell plain items. Our way blends material knowledge, making skills, and the use of know-how.

Matching Bimetallic Barrel Design to Material and Process Conditions

Bimetallic screw barrel design must fit the materials in use. High-filler PVC, recycled polymers, and engineering plastics each bring different wear and rust patterns. We adjust liner alloys, thickness, and barrel build to match.

Items like the Bimetallic Barrel use tungsten carbide bits in a rust-proof base. They suit rough and rusting work spots. This setup tackles the wear types noted before.

Advanced Manufacturing and Quality Control for Long-Life Barrels

Bimetallic screw barrel trust rests on steady making quality. At CHUANGRI SCREW, we use centrifugal casting, set heat treatments, and fine grinding. We add full check steps.

Our making ensures even liner thickness, firm metal bonds, and steady hardness. These parts together make a long life in hard work conditions.

Custom Screw and Barrel Systems to Reduce Wear at the Source

Reducing bimetallic screw barrel wear often starts with optimizing the screw itself. By adjusting screw geometry, compression ratios, and mixing sections, wear-inducing stress can be minimized.

Solutions such as the Bimetallic Injection Molding Screw and Bimetallic Twin-Screw are designed to work in harmony with bimetallic barrels. This system-level optimization improves material flow, lowers shear stress, and extends the life of both components.

FAQ

Q: What is the main advantage of a bimetallic screw barrel compared to a nitrided barrel?

A: A bimetallic screw barrel offers superior wear and corrosion resistance due to its alloy liner, resulting in longer service life and more stable processing in abrasive or corrosive applications.

Q: How long does a bimetallic screw barrel typically last in high-wear applications?

A: In high-filler or corrosive environments, a bimetallic screw barrel can last 30% or more longer than conventional barrels, depending on materials and operating conditions.

Q: How to choose the right bimetallic screw barrel for a specific material?

A: Selection should consider filler content, chemical reactivity, processing temperature, and throughput. Matching the liner alloy composition and barrel design to these factors is essential.

Q: Are bimetallic screw barrels suitable for recycled plastics processing?

A: Yes, bimetallic screw barrels are particularly effective for recycled plastics, where contaminants and fillers accelerate wear in standard barrels.

Q: Which factors most affect bimetallic screw barrel durability and longevity?

A: Key factors include alloy composition, manufacturing method, machining precision, and how well the barrel design matches the processing application.