What Are the Key Functions of an Injection Molding Machine Screw Barrel?

What Are the Key Functions of an Injection Molding Machine Screw Barrel?

How Does an Injection Molding Screw and Barrel Operate?

The Role of the Screw in Material Processing

The role of the screw in an injection mold machine is of utmost significance to process the materials with efficiency by performing three functions. Carrying and then melting and metering or pumping them, respectively. CHUANGRI SCREW is very much concerned to emphasize how significant it is to design the screw with efficiency to enhance the extrusion or injection molding process. The screw will rotate within the barrel to push the plastic pellets from the hopper to hot zones of the barrel where the pellets are melted in stages due to unwanted heat inputs and friction. The metering zone of screws provides a material supply of the melted one to the mold to maintain consistency in production and continuous high-quality product output.

The Importance of the Barrel in Maintaining Consistency

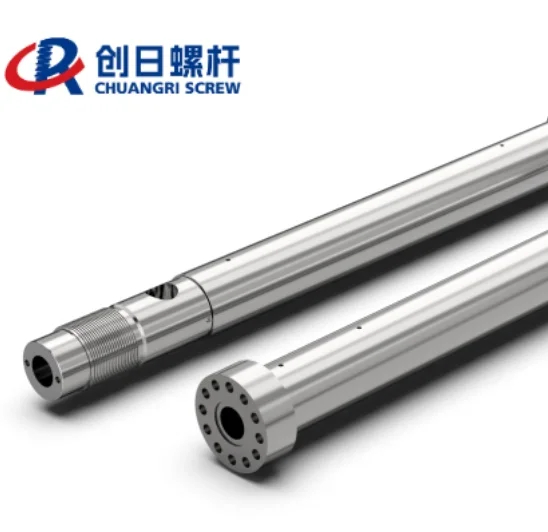

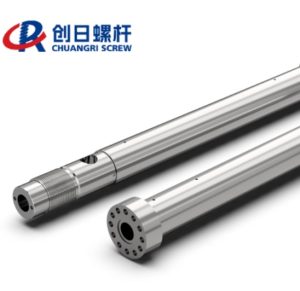

The barrel accommodates the screw and plays a significant role in achieving uniform temperature while processing the material effectively. CHUANGRI SCREW’s Injection Molding Barrel can be as long as 8000mm without joint for enhanced durability and stability. The ideal screw and barrel pairing delivers the highest production level and quality of finished product. The high-quality 38CrMoAlA or SKD61 material utilized ensures that the barrels are extremely wear-resistant and corrosion-resistant. This allows temperature to be evenly distributed in the process, reducing stress and optimizing material quality.

The barrel accommodates the screw and plays a significant role in achieving uniform temperature while processing the material effectively. CHUANGRI SCREW’s Injection Molding Barrel can be as long as 8000mm without joint for enhanced durability and stability. The ideal screw and barrel pairing delivers the highest production level and quality of finished product. The high-quality 38CrMoAlA or SKD61 material utilized ensures that the barrels are extremely wear-resistant and corrosion-resistant. This allows temperature to be evenly distributed in the process, reducing stress and optimizing material quality.

Why Is Material Compatibility Critical for Injection Molding Screw Barrels?

Factors Affecting Material Selection for Screws and Barrels

The effectiveness of screws and barrels in an injection molding machine largely relies on material compatibility utilized therein. Such properties as plastic wear and corrosion resistance are engaged in their functioning and problems, like thermal stability and processing, which are also fundamental to the selection of materials employed in these components. For instance, nitrided screws are very well suited for plastic application, thanks to their extremely high surface hardness levels, which achieve the quality of HV1000. Conversely, tungsten carbide coatings bimetallic screws are highly recommended to effectively deal with abrasive materials or corrosive chemicals.

The effectiveness of screws and barrels in an injection molding machine largely relies on material compatibility utilized therein. Such properties as plastic wear and corrosion resistance are engaged in their functioning and problems, like thermal stability and processing, which are also fundamental to the selection of materials employed in these components. For instance, nitrided screws are very well suited for plastic application, thanks to their extremely high surface hardness levels, which achieve the quality of HV1000. Conversely, tungsten carbide coatings bimetallic screws are highly recommended to effectively deal with abrasive materials or corrosive chemicals.

Common Issues Caused by Incompatible Materials

While different materials are compounded by employing the process of injection molding, it can lead to problems in the process of a different kind. For example, a poor coat of fillers leads to screws or barrels getting worn out faster. Moreover, corrosion can also occur while incompatibilized materials receive a chemical reaction with polymers that could lead to machinery damage. These issues, subsequently, not only reduce the lifespan of the equipment but also negatively impact the quality of the product by causing abnormal melting or contamination.

How Can You Ensure Optimal Performance of Your Injection Molding Screw and Barrel?

Cleaning Procedures for Screws and Barrels

Injection molding machine barrels and screws need to be cleaned so that they are able to perform at best. Cleaning is critical as accumulation of residue material will be a problem, i.e., melting or contamination in subsequent production runs. CHUANGRI SCREW advises that cleaning operations are undertaken using the right tools to remove deposits without causing damage to screws or barrel surfaces. For instance, purging compounds may be utilized to remove any residual plastic while reducing downtime.

Regular Inspection Tips for Early Problem Detection

It’s crucial to regularly check for signs of wear or damage in screws and barrels at a stage. It’s essential to monitor surface roughness as well as component alignment and straightness. Early solution of problems can prevent manufacturers from having to pay costly repair or replacement costs in the future.

Why Should You Choose CHUANGRI SCREW for Your Injection Molding Machine Screw Barrel Needs?

Precision Engineering for Enhanced Efficiency

Our manufacturing engineers have technical expertise and hands-on knowledge, the prime driver of optimizing efficiency, lowering cost and ensuring quality in the product. We work with the latest CNC machine tools for machining screws and barrels with precision. This precision not only optimizes material movement but also reduces wastage of energy during injection molding.

Our manufacturing engineers have technical expertise and hands-on knowledge, the prime driver of optimizing efficiency, lowering cost and ensuring quality in the product. We work with the latest CNC machine tools for machining screws and barrels with precision. This precision not only optimizes material movement but also reduces wastage of energy during injection molding.

In our manufacturing operations, we use nitriding and bimetallic plating with quenching in a bid to improve the heat resistance as well as surface hardness of our products. For example, screws that go through the nitriding process attain up to 65-70 HRC, a level which makes them extremely long-lasting even under adverse conditions. Through such practices, we maintain that our screw barrels continue to give consistent performance resulting in improved efficiency as well as optimum product quality.

Materials Used to Ensure Longevity and Reliability

The selection of material is required to render injection molding screw barrels durable and reliable. We employ excellent materials, including 38CrMoAlA steel, AISI 4140 steel and Hastelloy C276 for our abrasion resistance, corrosion resistance and thermal resistance. Our bimetallic barrels also have tungsten carbide particles in an even distribution of a corrosion-resistant nickel alloy matrix. This design very significantly extends the barrels’ life while maintaining performance under abrasive or corrosive material handling.

Through the combination of components and advanced manufacturing methods, such as centrifugal casting and HVOF tungsten carbide coating, we guarantee that our screw barrels are of the highest standard in the industry.

Customization Options Tailored to Your Specific Requirements

Every manufacturing line has its specific needs that CHUANGRI SCREW addresses by providing a wide range of customization options for injection molding screw barrels. With our research and development team being professionals utilizing the latest design technology software such as AutoCAD and SolidWorks, we are capable of supplying tailor-made solutions according to your specifications. From plastics screws or for specialty applications with closely packed resins, we can reformulate or replicate products based on your requirements.

Frequently Asked Questions about Injection Molding Machine Screw Barrel

Q: What screws are used in injection molding machines?

A: The most common screws used in injection moulding machines are standard screws. Standard screws have equal pitch and diameter and are typically manufactured from chrome-molybdenum or nickel alloy steel. Standard screws are of general-purpose type and can process any kind of material from low-viscosity plastics to high-viscosity plastics.

Q: What is the purpose of the screw in the injection barrel?

A: The basic function of an extrusion or injection molding screw is simply to deliver the material to the die or mold in a uniform mixture of pressure and resin to fill the mold cavities appropriately in an attempt to produce an acceptable plastic part.

Q: What is a barrel in an injection molding machine?

A: Injection molding barrel is a cylindrical product which is a very important component of the injection molding machine. It is located between the mold cavity and the plasticizing screw. It serves as a chamber for melting and processing plastic materials.