Exploring the Design Elements of Conical Extruder Twin Screw Barrels

Exploring the Design Elements of Conical Extruder Twin Screw Barrels

The Role of Conical Twin-Screw Barrels in Extrusion

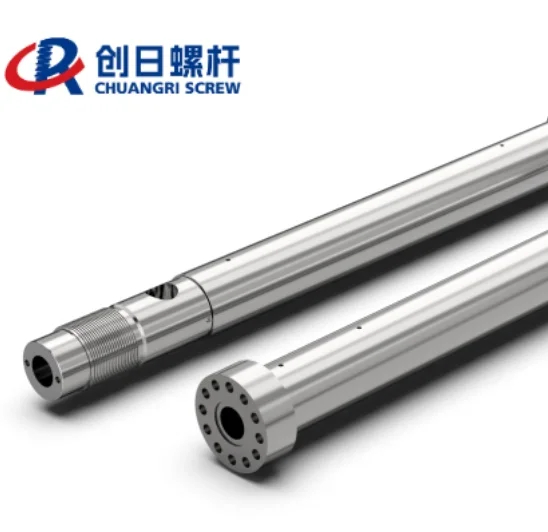

Overview of Conical Twin-Screw Barrels

Conical twin screw barrels are a key part of a plastic extrusion device, which through the use of different types of screw structures, in combination with various molds and auxiliary machines, can produce a variety of products such as PVC pipe, profile, sheet and board. Their special structure enables the blending of materials and temperature regulation both essential factors in producing top-notch results.

CHUANGRI SCREW is recognized as a player in this industry sector and provides cutting-edge conical twin screw barrels tailored to meet various industrial requirements. The unique conical twin screw barrel is specifically crafted for manufacturing WPC boards, doors, form boards, specialty PVC flooring and other PVC items. This particular design by CHUANGRI SCREW guarantees the processing of both new and recycled materials.

CHUANGRI SCREW’s Conical Twin-Screw Barrel Offerings

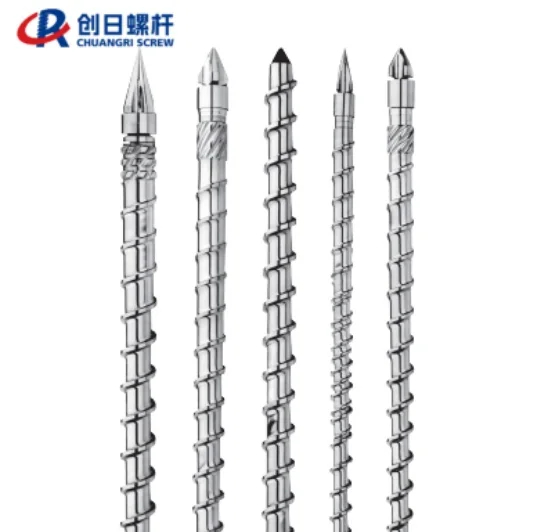

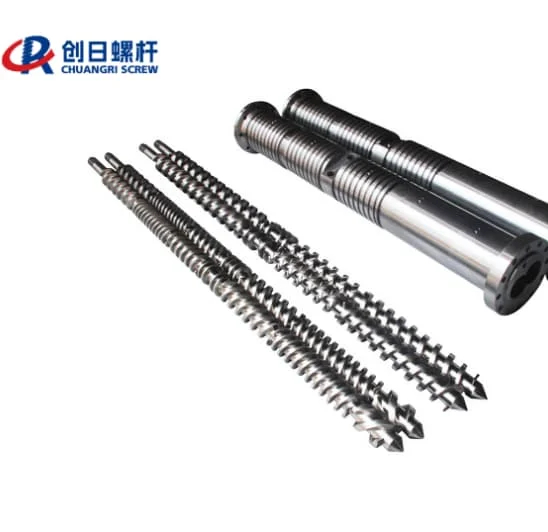

CHUANGRI SCREW offers a selection of twin screw barrels designed to cater to different extrusion needs efficiently. Their innovative bimetallic and SKD inner lining technology enables the handling of both recycled materials with ease. This ensures durability and efficiency when dealing with raw materials high in calcium carbonate. The enhanced screw lifespan by more than 30% makes it a popular option among numerous manufacturers.

The company also highlights the importance of tailoring products to fit manufacturing settings. They provide structural options for screws tailored to high calcium content, medium calcium content and low calcium content ensuring that each screw is perfectly suited for its purpose. With a selection of over 10 screw designs crafted to match different raw material compositions, productivity and efficiency are boosted through optimized performance.

Key Design Considerations for Twin Screw Barrels

Material Selection and Durability

Material selection is a critical factor while designing twin screw barrels since these parts need to endure severe conditions of high stress and temperature. Attention should be paid to corrosion-resistant materials like nitriding steel and stainless steel for enduring tough processing conditions. Also choose high-strength materials such as tool steel to withstand mechanical stresses from high torques, pressures and abrasives. CHUANGRI SCREW opts for materials like 38CrMoAla and SK61 to guarantee their products can handle challenging environments effectively, such as the SPC Conical Twin-Screw Barrel. The raw material is capable of incorporating 5%–300% calcium carbonate. In environments with any calcium carbonate ratio, the screw lifespan has extended by over 30%.

Combined with hardening, coating and other surface treatments to improve wear resistance and extend service life. The thermal stability design maintains structural integrity and prevents deformation under cyclic heating and cooling. CHUANGRI SCREW applies a tungsten carbide alloy coating to the screws areas like the root diameter and outer diameter as well as the thread surface to boost durability, against wear and corrosion significantly. The careful choice of materials not prolongs the screw’s lifespan but also ensures steady performance over time.

Geometry and Configuration Impact

Force Distribution & Side Load Mitigation

Adopt configurations like parallel leg designs or intermeshing screw geometries to evenly distribute mechanical forces, reducing side loading (as seen in double-piston systems). This minimizes wear and extends the barrel’s lifespan.

Application-Specific Geometry Optimization

Tailor screw pitch, flight depth, and barrel length based on material properties (e.g., viscosity, abrasiveness) and process requirements. Complex geometries (e.g., cogged profiles) enhance mixing efficiency for intricate formulations.

Alignment Precision

Ensure rigid mounting and alignment during installation to prevent misalignment-induced stress, akin to optimizing pump systems. Use precision dovetail slide dynamics principles for stable screw positioning under high torque.

By paying attention to details, such as the structure of threads and the setup of flow channels, CHUANGRI SCREW improves the efficiency of plasticization and mixing processes.

Enhancing Performance with Advanced Technologies

Innovative Manufacturing Techniques

CHUANGRI SCREW implements manufacturing processes to maintain high-level quality in conical twin screw barrels production successfully. The company utilizes advanced CNC machining equipment with various processes, including threading, turning, milling, grinding, polishing, nitriding, quenching, bimetallic coatings and alloy coatings. These advanced processes play an important role in determining the accuracy and consistency of screws and barrel manufacturing.

Nitriding and bimetallic treatment are applied to maximize the efficiency and strength of the screws. It is achieved by subjecting the screws to a heat treatment process in a mixture of nitrogen and hydrogen gases to create a layer of chromium nitride (CrN) with high thermal stability. The PVC Conical Twin-Screw Barrel uses this technology processing. This detailed method guarantees that CHUANGRI SCREW’s products are capable of enduring the temperatures produced during plastic extrusion or molding operations.

Quality Assurance and Testing Protocols

Quality control is an aspect of CHUANGRI SCREW’s business practices. The company strictly adheres to the ISO 9001 Standard of 2008 to maintain consistent high-quality manufacturing processes. Every screw and barrel undergo inspection protocols to ensure they adhere to global quality standards.

By adopting a quality control mechanism, CHUANGRI SCREW not only controls possible troubles before they are faced but also earns the trust of its clientele by continuously offering consistent products. Their commitment to excellence is established through their potential to offer individualized solutions which address industry demands, yet assure superior levels of quality and performance.

Applications and Benefits of Using CHUANGRI SCREW’s Products

Diverse Industrial Applications

CHUANGRI SCREW’s conical twin screw barrels are components that meet the needs of diverse industries with their specialized design aimed at producing WPC boards and doors among other PVC products, like foam boards and SPC flooring options as well. This flexibility enables manufacturers to employ these barrels in fields guaranteeing effective production processes and excellent results.

Economic and Operational Advantages

CHUANGRI SCREW’s conical twin screw barrels provide cost savings advantages to manufacturers looking to optimize their operational expenses, due to their extended lifespan and reduced maintenance requirements resulting in less frequent replacements.

Furthermore, the improved strength and efficiency of these barrels help boost productivity. By reducing downtime and maintaining quality companies can increase their output without added expenses.

When companies opt for CHUANGRI SCREW’s twin screw barrels they not only save on operational expenses but also acquire cutting-edge technology that boosts production efficiency overall. Welcome to consult us!

Frequently Asked Questions

Q: What is a conical twin screw extruder?

A: Through compounding and extrusion technology, the twin screw extruder equipment is designed for complete plants for processing PVC from raw material feeding phases and dry blend to heat-cooling mixture of pellets environment.

Q: What is the difference between conical and parallel extruders?

A: Parallel twin-screw extruder screw is longer than conical twin-screw extruder. So, the plasticizing capacity of the parallel twin-screw extruder is better and the kneading of the materials is more uniform.

Q: What are the key advantages of conical twin screw barrels in tire factory extrusion systems?

A: Conical twin screw barrels are more durable and precise for tire production, with better material mixing (e.g., rubber, additives) and wear resistance. The conical design enhances shear efficiency and reduces energy consumption, applicable to high-torque applications like 250kW extruders.

Q: How do material choices like R-HDPE impact conical screw barrel performance?

A: The use of R-HDPE (recycled high-density polyethylene) in screw barrels provides improved corrosion resistance and reduces wear during high-temperature processing. It extends barrel life while maintaining stability in harsh tire production environments.