Exploring the Impact of Friction on Single Screw Extruder Barrel Productivity

Exploring the Impact of Friction on Single Screw Extruder Barrel Productivity

What Role Does Friction Play in Single Screw Extruder Barrels?

How Friction Affects Material Flow Efficiency

Friction affects how efficiently material flows through single screw extruder barrels by directly influencing efficiency. The contact between the screw, barrel walls, and processed material creates friction. This friction is vital for moving solid materials along the barrel. CHUANGRI SCREW‘s production engineers stress that maintaining ideal friction levels is essential for a smooth extrusion process. A balanced friction level supports consistent material flow. It also prevents problems such as blockages or uneven flow rates. This balance further enhances productivity and reduces costs.

The Connection Between Friction and Heat Generation in Barrels

The heat generated inside screw extruder barrels is closely linked to friction levels during material conveying and melting in the mixing process. During this process of moving and blending materials in the barrel, thermal forces help melt the plastic material. This heat boosts plasticizing performance by supporting efficient plastic melting. However, excessive or uncontrolled friction can lead to overheating. Overheating harms the material quality. It also speeds up wear on both screws and barrels.

Can Optimizing Friction Improve Barrel Performance?

Optimizing screw extruder barrel efficiency through precise friction control delivers measurable performance gains. Manufacturers can enhance the surface finish and design of screws and barrels. This balances reduced energy consumption with increased output. This approach yields benefits.

How Does Barrel Design Influence Friction Levels?

The Importance of Barrel Surface Finish on Friction

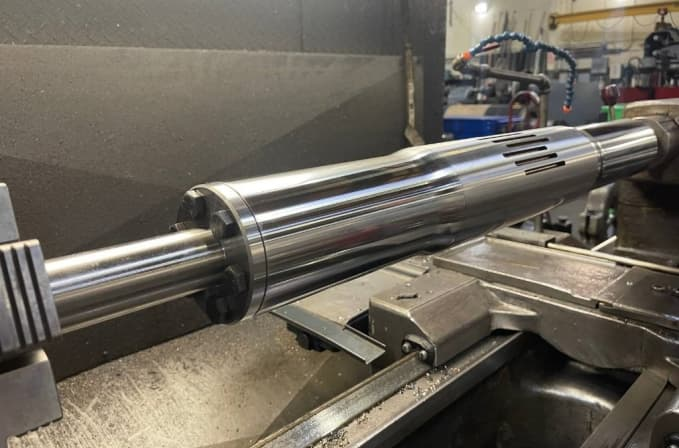

The smoothness of a barrel’s surface is crucial in controlling friction when extruding materials. A polished surface helps in reducing resistance without compromising the ability to handle materials effectively. CHUANGRI SCREW uses polishing methods, such as belt polishing with different grain sizes to achieve a highly smooth surface. This helps prevent materials from sticking to surfaces, ensuring a continuous flow and minimizing delays in processing.

Material Selection and Its Effect on Friction Dynamics

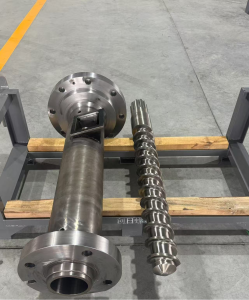

The friction characteristics and overall performance of extruder barrels are directly affected by their material composition. Premium alloys like 38CrMoAlA and nickel-based variants deliver optimal results due to their unique properties. These ensure smooth barrel operation under tough conditions. CHUANGRI SCREW’s Bimetallic Barrel uses tungsten carbide particles in a corrosion mix to handle rough fillers and high heat. These materials boost longevity while keeping friction at levels for smooth processing.

How Barrel Geometry Impacts Productivity

The barrel’s design influences how effectively materials move during extrusion. It directly affects output by altering material behavior on the barrel’s internal surfaces. The length-to-diameter ratio and groove design impact pressure distribution and material melting efficiency. CHUANGRI SCREW provides single screw extruder barrels with a variety of length ratios ranging from 7 to 55. These are customized to meet specific requirements.. This customized approach ensures effective material flow control and consistent melting during extrusion.

What Are the Challenges of Managing Friction in Single Screw Extruder Barrels?

Common Issues Caused by Excessive Friction

High friction levels in screw extruder barrels can damage interior surfaces over time. As the screw rubs against the barrel walls and materials interact continuously, mechanical stresses form. These stresses gradually wear down the equipment. Improper levels of friction can cause material flow and worsen wear in specific areas over time. It not only shortens the barrels’ lifespan but also increases maintenance costs and causes production delays.

Strategies to Reduce Undesirable Friction

Reducing resistance in single screw extruder barrels demands a thorough approach. This integrates choosing suitable materials, refining design, and applying advanced manufacturing methods.

- Selecting Suitable Materials: Picking the right materials is vital for minimizing friction problems. CHUANGRI SCREW offers bimetalsmade with nickel-based alloys. These materials provide excellent resistance to wear and corrosion, especially when processing abrasive substances and reactive fillers.

- Surface Finishing Techniques: Improving screw and barrel durability involves techniques like nitriding or electroplating. These create stress-resistant layers. CHUANGRI SCREW’s nitriding process achieves a hardness of up to 70 HRC. This greatly improves wear resistance.

- Precision Engineering: Precise screw and barrel design is vital. Their geometry directly influences friction control and material flow efficiency while minimizing energy waste. CHUANGRI SCREW offers customized screw extruder barrels with tailored length-to-diameter ratios. These meet specific application needs.

- Regular Maintenance: Consistent upkeep is essential. It involves following a regular inspection schedule. This detects issues like wear and overheating early. Prompt action prevents larger problems later.

By adopting these strategies, manufacturers can boost efficiency. They can also lower costs tied to equipment maintenance and energy use.

Why Choose CHUANGRI SCREW for Your Single Screw Extruder Barrel Needs?

Our Commitment to Precision and Quality Manufacturing

At CHUANGRI SCREW, quality isn’t just a promise – it’s a measurable output of our manufacturing process. We’ve built our reputation on three pillars of excellence:

At CHUANGRI SCREW, quality isn’t just a promise – it’s a measurable output of our manufacturing process. We’ve built our reputation on three pillars of excellence:

Material Excellence: Hand-selected, mill-certified alloys. Rigorous material testing (spectral analysis, hardness verification). Batch-level traceability from raw material to finished product

Engineering Expertise: Advanced CNC machining (±0.01mm tolerance). Proprietary heat treatment protocols. In-house metallurgical laboratory

Our engineering team uses advanced technologies for precise product development. This thorough approach enables us to meet the needs of each client, providing reliable and cost-effective products.

Key Features of CHUANGRI SCREW’s Single Screw Extruder Barrels

High-Performance Materials for Enhanced Durability

At CHUANGRI SCREW, we engineer extruder barrels to withstand the most demanding processing conditions. Our material science approach ensures maximum service life through premium alloy selection, such as the 38CrMoAlA Alloy and AISI 4140 Chromoly Steel. Our proprietary bimetallic construction combines tungsten carbide particles (88-92 HRA hardness), nickel-chrome alloy matrix (45-50 HRC), precision laser-clad deposition and uniform particle distribution. This matrix effectively resists corrosion. This unique combination ensures our barrels withstand harsh fillers and extreme heat conditions. It significantly extends their operational lifespan.

Advanced Surface Treatment Techniques to Minimize Friction

To improve efficiency and durability, we use advanced surface treatment methods. Our nitriding process forms a hardened layer on screws. This reaches a peak hardness of 70 HRC. It enhances stress resilience while maintaining strong heat conduction. Our electroplating methods use chrome plating with thicknesses from 10 to 50 microns. This enhances surface smoothness and reduces friction during operation.

Choose CHUANGRI SCREW for screw extruder barrels that deliver exceptional durability and efficiency. Our barrels optimize performance for your extrusion needs. Let us assist you about extrusion operations with tailored solutions designed to boost productivity.

Frequently Asked Questions about Single Screw Extruder Barrel

Q: What is a single screw extruder?

A: Single-screw extruders are the most widely used polymer extrusion machines. Although their utility as mixing equipment is somewhat limited, many compounding operations have at least one. Their key advantage is a low cost, straightforward design, durability, and a strong performance-to-cost ratio.

Q: What is the difference between single and double screw extruders?

A: Twin screw extruders are more effective than single screw extruders at achieving uniform mixing of ingredients like additives, fillers, and liquids. Single screw extruders can improve mixing with mixing elements. However, they are less effective than twin screw extruders.

Q: What causes wear in a single screw extruder barrel?

A: Wear in a single screw extruder barrel results from ongoing friction, heat, and pressure from processed materials. Abrasive fillers, high shear forces, and poor maintenance speed up barrel degradation.

Q: How can I extend the lifespan of a single screw extruder barrel?

A: To prolong the lifespan, maintain equipment properly and use high-quality materials. Optimize the extrusion process to avoid excessive temperatures and pressures. Regular inspections and prompt repairs are also vital.