How to Avoid Pitfalls in Conical Screw Barrel Installation

How to Avoid Pitfalls in Conical Screw Barrel Installation

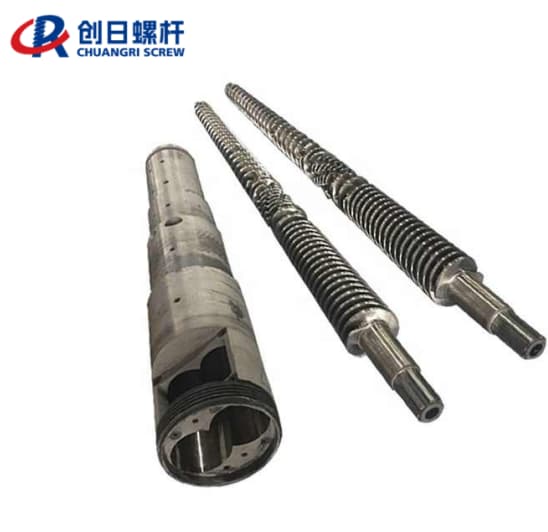

Common Installation Mistakes of Conical Twin Screw Barrel

Misalignment Between Screw and Barrel Causing Rub or Noise

Improper alignment ranks among the top errors during conical twin screw barrel installation. Even minor mismatches between the screw shaft and barrel bore can lead to rubbing. This creates unwanted noise and speeds up wear. Over time, such issues harm product quality and shorten the barrel’s lifespan.

Incorrect Screw-to-Barrel Clearance

The gap between the screw and barrel affects melt flow and extrusion performance. A gap that’s too wide causes polymer leakage, reducing output. A gap that’s too narrow increases friction, generating excess heat and damaging the alloy layer. For most conical screw models, the clearance should stay between 0.03 and 0.08 mm, depending on the barrel size.

Wrong Barrel Orientation or Support Frame Height Issues

Incorrect barrel positioning or improper frame height creates stress along the axis. This can result in spline mismatches, vibrations, or inconsistent extrusion. Many problems arise from overlooking these basic mechanical factors. Proper setup alignment prevents such risks.

Preparation Steps Before Installing the Conical Screw Barrel

Cleaning and Inspecting the Extruder Frame and Components

Before installing, remove all old debris, such as plastic residue, carbon buildup, or rust. A clean frame surface ensures a secure fit and steady operation. This step avoids instability during use.

Ensuring the Machine Frame is Level and Horizontal

An uneven frame base leads to ongoing alignment issues. Checking the frame with a spirit level before installation prevents tolerance shifts during operation. This simple step ensures long-term stability.

Verifying All Heaters, Thermocouples, Fasteners Removed or Released

Leftover components, like heaters or fasteners, can block smooth barrel insertion. Using a checklist to remove or loosen these parts avoids costly errors. This preparation saves time and effort.

| Preparation Step | Importance | Tools Needed |

| Cleaning surfaces | Prevents gaps and instability | Solvent, brush |

| Leveling frame | Avoids long-term misalignment | Spirit level |

| Removing accessories | Prevents installation blockage | Wrench, screwdriver |

Step-by-Step Proper Installation Procedure for Conical Twin Screw Barrel

Inserting Screws Symmetrically into the Barrel Small End First

Insert both screws together from the small end of the barrel. This approach ensures even thread stress. It also maintains balance during initial placement, reducing the risk of damage.

Adjusting Axial Position / Backward Movement Toward the Gearbox

Set the correct backward distance to ensure a stable spline connection. Too little clearance can lock the screw in place. Too much clearance causes vibrations and uneven melt flow. Proper adjustment avoids these issues.

Installing Gaskets or Shims to Set the Correct Screw-to-Barrel Clearance

Use metal shims to achieve precise spacing. These ensure optimal plastification while protecting the barrel from wear. Correct clearance enhances performance and longevity.

Tightening Large Barrel Nut and Securing with Correct Torque

Tighten the barrel nut according to torque guidelines. Over-tightening may crack the flange. Under-tightening can lead to leaks. Keep a record of torque values for maintenance logs to track performance.

Critical Alignment, Measurement, and Tolerance Checks

Measuring Screw Backward Distance, Using Reference Points

Accurate measurement of the screw’s backward distance ensures smooth gearbox spline engagement. For conical twin screws, like SJZ models, a 2–3 mm backward movement is typically needed. This prevents operational issues.

Checking Barrel Height Relative to Gearbox or Distribution Box

The barrel’s height must align with the gearbox to ensure a precise spline connection. A mismatch as small as 0.5 mm can accelerate wear. Proper height adjustment maintains equipment durability.

Using Dial Indicators or Rulers to Confirm Parallelism and Spline Alignment

Dial indicators help measure concentricity, preventing rotational wobble. Checking parallelism ensures steady extrusion without vibrations. These tools are essential for precise installation.

What Are Acceptable Tolerances / Clearance Values for Conical Twin Screw Barrel

Industry standards recommend a clearance of 0.03 mm for smaller barrels and up to 0.1 mm for larger ones. Always verify against the manufacturer’s specifications to ensure accuracy.

How to Prevent Damage After Installation & Maintenance Tips

Regular Inspection for Wear Between the Screw and the Barrel

Check wear depth regularly to plan replacements. Using ultrasonic gauges provides precise measurements. This helps avoid unexpected failures and extends equipment life.

Avoiding Operation without Feed / Preventing Screw Migration

Running the extruder without feed causes overheating. Worn thrust rings may also allow screws to shift toward the gearbox, leading to damage. Consistent feed prevents these risks.

Temperature Control, Lubrication, Material Cleanliness

Maintain stable heating zones and lubricate the gearbox properly. Clean feed materials reduce contamination risks. These steps protect components and ensure smooth operation.

How to Clean, Polish & Handle Abrasives or Additives

Processing PVC with high CaCO₃ content requires regular cleaning. Polishing screw surfaces prevents filler buildup. Frequent maintenance ensures consistent performance.

Why Choose CHUANGRI SCREW for Conical Twin Screw Barrel Solutions

Advanced Bimetallic and SKD Inner Lining Technology Extending Service Life

At CHUANGRI SCREW, we use SKD lining and tungsten carbide coatings to boost wear resistance. These technologies extend barrel life by over 30% compared to standard nitrided barrels.

Customized Structural Designs for Different Calcium Carbonate Ratios in PVC/WPC Applications

Different formulations need tailored designs. Our WPC Conical Twin-Screw Barrel (SJZ 65/132) ensures uniform plastification for calcium carbonate loadings from 5% to 300%. This versatility suits various applications.

Strict Quality Control and CNC Precision Machining for Better Alignment and Fit

Every barrel undergoes CNC turning, honing, and polishing to achieve a surface roughness of Ra ≤ 0.4 μm. This ensures smooth screw rotation and precise alignment.

Global Service and Fast Delivery with Packaging That Protects Against Transport Damage

We ship globally from Zhoushan, using wooden crate packaging, film wrapping, and anti-rust oil. This protects barrels from damage or corrosion during transport, ensuring they arrive in perfect condition.

Products closely related to installation precision include:

-

SPC Conical Twin-Screw Barrel (SJZ 110/220) – Ideal for flooring, ensuring consistent melt quality with heavy fillers.

-

PVC Conical Twin-Screw Barrel (SJZ 92/188) – Designed for pipe extrusion, with bimetallic lining for extended wear resistance.

-

WPC Conical Twin-Screw Barrel (SJZ 65/132) – Suited for doors and boards, compatible with both virgin and recycled PVC.

FAQ

Q: Which brand of conical twin screw barrel is reliable for long service life?

A: Brands like CHUANGRI SCREW, with bimetallic and SKD lining, offer durability and minimal downtime for high-filler extrusion.

Q: How to choose the best conical twin screw barrel for PVC extrusion?

A: Consider filler ratio, machine size, and output needs. For example, the PVC Conical Twin-Screw Barrel (SJZ 92/188) excels in pipe production with reliable stability.

Q: What is the difference between bimetallic conical screw barrels and nitrided versions?

A: Bimetallic barrels resist wear and corrosion better. Nitrided versions are more budget-friendly but less suited for abrasive fillers.

Q: Top companies for conical screw barrel solutions—what makes them stand out?

A: Leaders like CHUANGRI SCREW excel with CNC precision machining, advanced coatings, and dependable global logistics.

Q: How often should screw-to-barrel clearance be measured in conical twin screw extruders?

A: Measure every 3–6 months. For PVC with high CaCO₃, check more often to prevent costly failures.